Mitsubishi Outlander XL. Manual - part 474

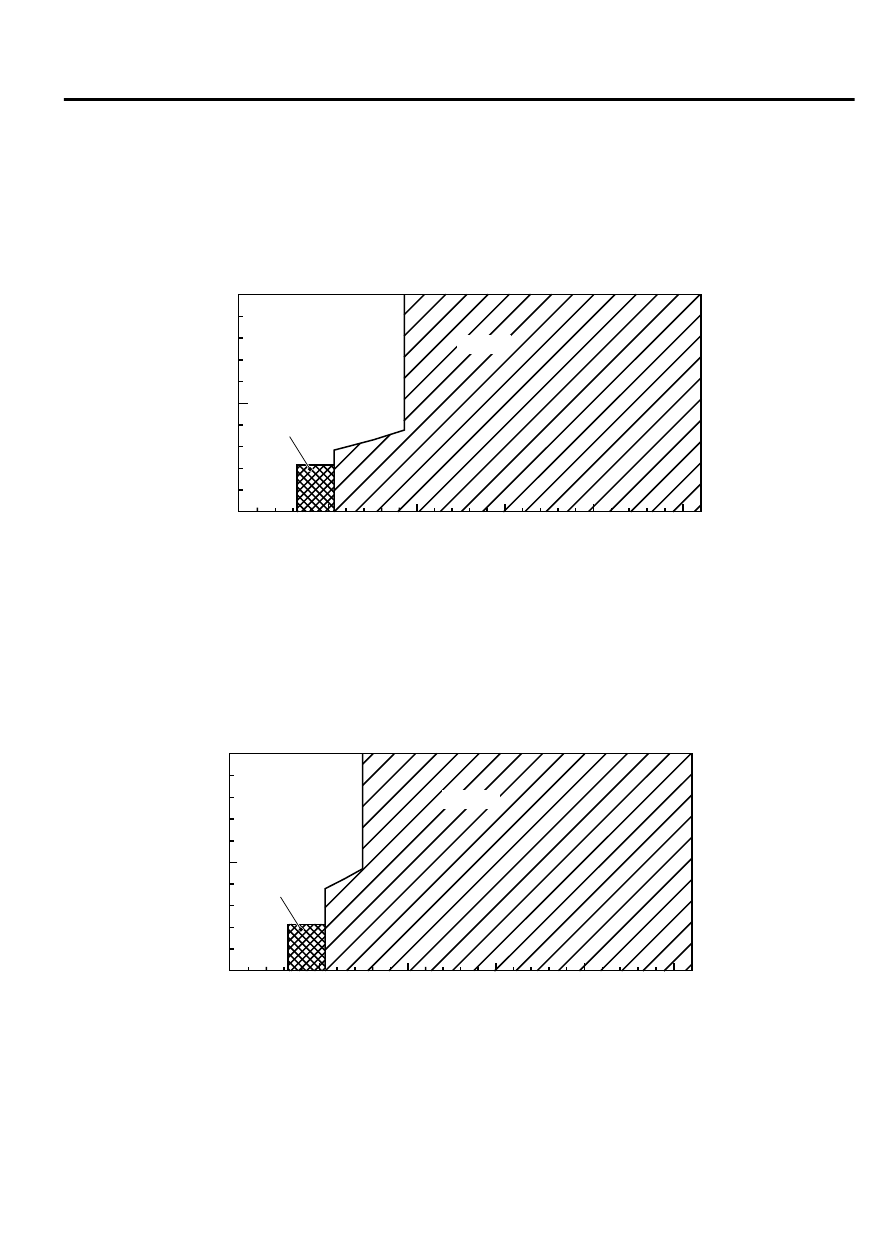

TORQUE CONVERTER CLUTCH

CONTROL

6TH GEAR RANGE

0

50

100

0 (0)

50 (31)

100 (62)

150 (93)

200 (124)

250 (155)

ZC6045590000

Lock-up

Disengaged

Throttle

opening (%)

Vehicle speed km/h (mph)

Slip lock-up

5TH GEAR RANGE

0

50

100

0 (0)

50 (31)

100 (62)

150 (93)

200 (124)

250 (155)

ZC6045580000

Lock-up

Disengaged

Throttle

opening (%)

Vehicle speed km/h (mph)

Slip lock-up

AUTOMATIC TRANSAXLE MECHANICAL

23A-11

GENERAL INFORMATION