Mitsubishi Outlander XL. Manual - part 309

DIAGNOSIS

Required Special Tools:

⦆

MB991958: Scan Tool (M.U.T.-III Sub Assembly)

⦆

MB991824: V.C.I.

⦆

MB991827: USB Cable

⦆

MB991910: Main Harness A

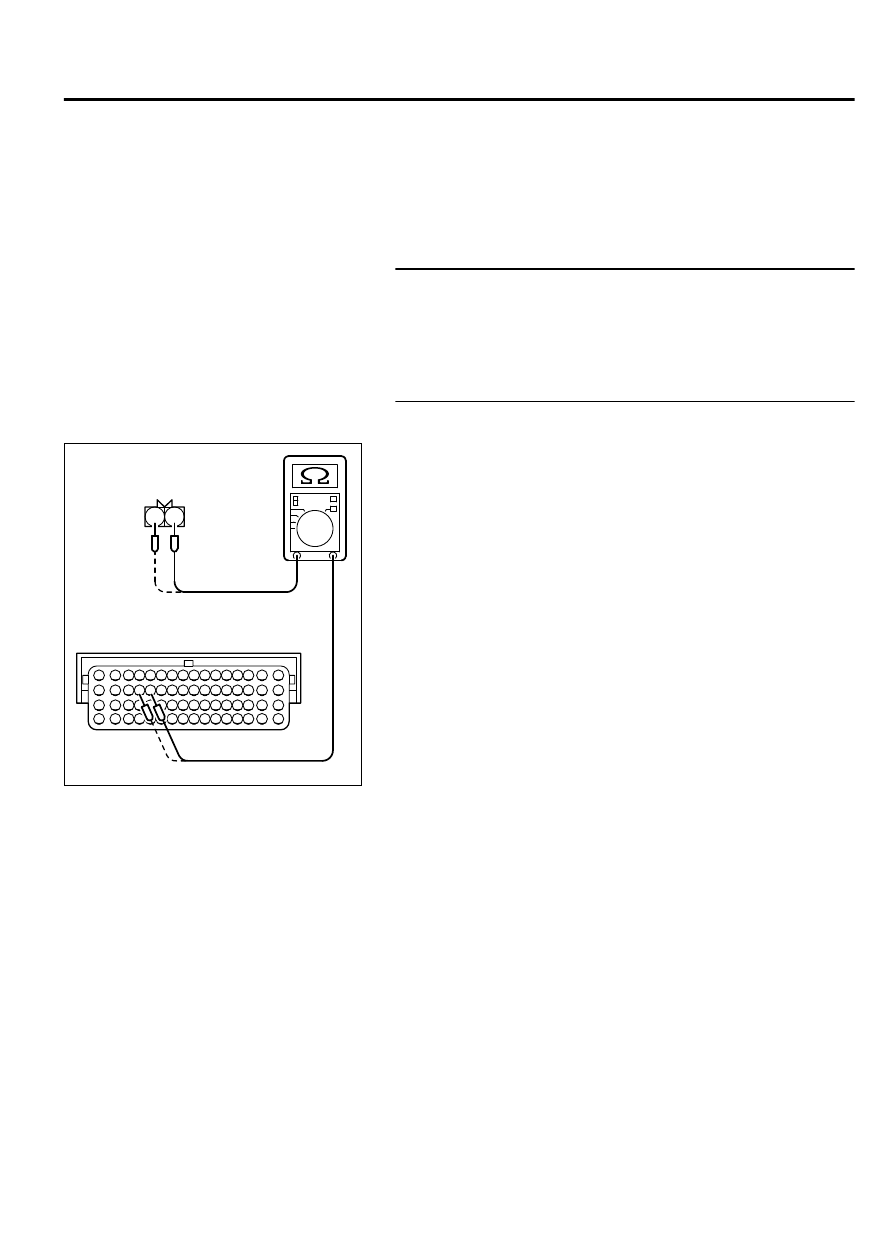

STEP 1. Check harness connector B-20 at the knock sensor

2 and harness connector B-10 at ECM for damage.

Q:Is the harness connector in good condition?

YES:

Go to Step 2.

NO:

Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection P.00E-2. Then go to Step 4.

STEP 2. Check for harness damage between knock sensor

2 connector B-20 and ECM connector B-10.

ZK604049

16

15 14 13 12 11 10 9 8 7 6 5 4

3

2

1

32

31 30 29 28 27 26 25 24 23 22 21 20 19 18

17

48

47 46 45 44 43 42 41 40 39 38 37 36 35 34

33

64

63 62 61 60 59 58 57 56 55 54 53 52 51 50

49

1

2

AA00

B-20 harness connector:

component side

B-10 harness connector:

component side

(1)

Disconnect the connector B-20 and B-10 measure at the

harness side.

(2)

Measure the resistance between connector B-20 and

connector B-10.

a

.

Knock sensor 1 connector B-20 (terminal No. 1) and ECM

connector B-10 (terminal No. 28).

b

.

Knock sensor 1 connector B-20 (terminal No. 2) and ECM

connector B-10 (terminal No. 29).

⦆

Should be less than 2 ohms.

Q:Is the measured resistance less than 2 ohms?

YES:

Then go to Step 3.

NO:

Repair it. Then go to Step 4.

MULTIPORT INJECTION SYSTEM (MFI) <DIAGNOSIS>

13Ab-431

DIAGNOSTIC TROUBLE CODE PROCEDURES