Mitsubishi Outlander XL. Manual - part 191

6.

Install the engine oil filler cap.

7.

Let the engine run for a few minutes.

8.

Stop the engine, and then check the oil level using the oil

dipstick after a few minutes.

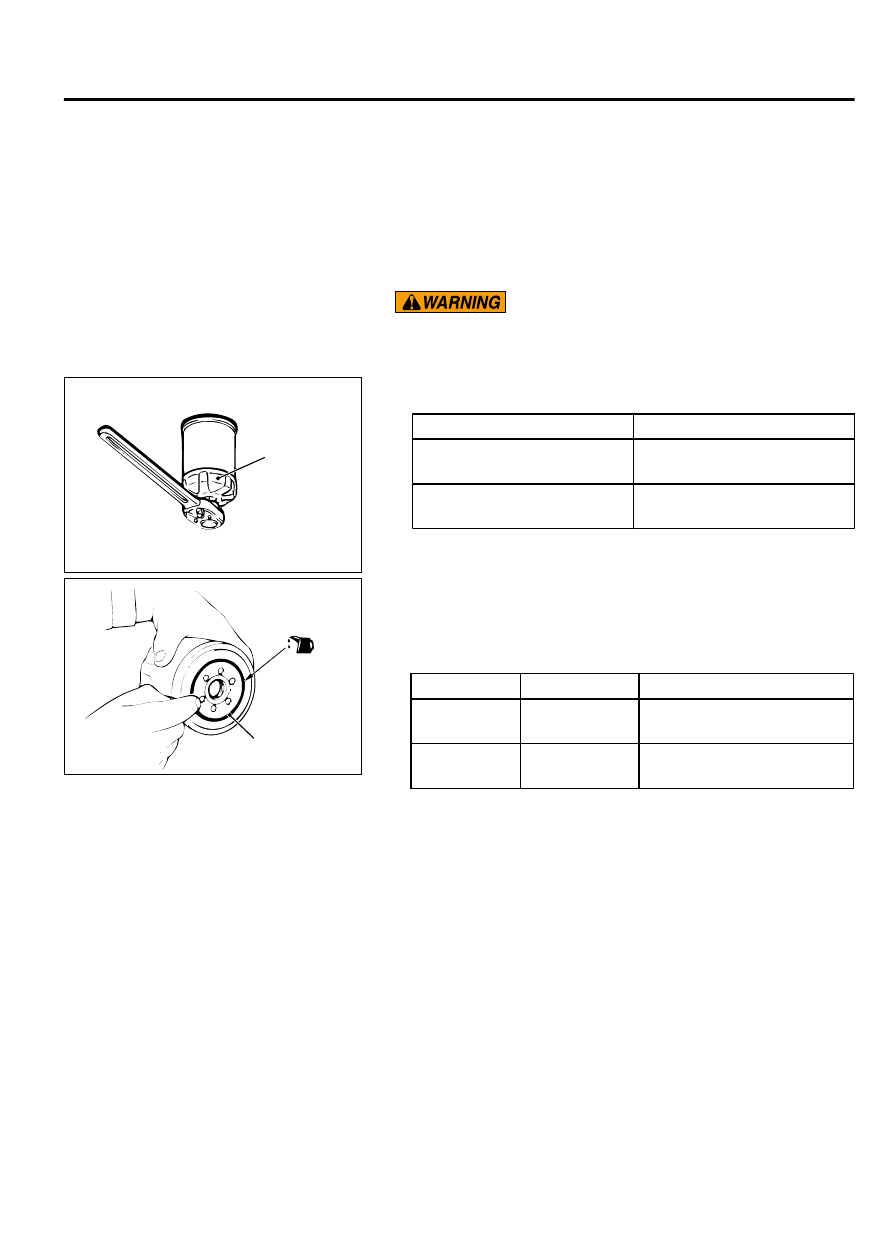

ENGINE OIL FILTER REPLACEMENT

M11201000011USA0000010000

1.

Start the engine and allow it to warm up until the temperature

of the coolant reaches 80 - 90°C (176 - 194°F)

Use care as oil could be hot.

2.

Remove the engine oil filler cap.

3.

Remove the drain plug to drain oil.

ZC601081

MB991828,

MB991396

or equivalent

0000

4.

Use the respective tool in the following table to remove the

engine oil filter.

Number

Special tool

MD332687 or MD365876

Oil filter wrench (MB991828)

or equivalent

MD360935

Oil filter wrench (MB991396)

or equivalent

5.

Clean the filter bracket side mounting surface and ensure the

old O-ring has been removed.

ZC601082

O-ring

0001

6.

Apply a small amount of engine oil to the O-ring of the new oil

filter.

7.

Screw on the oil filter by hand until it touches the surface of

the flange and then tighten it with an oil filter wrench.

Number

Special tool

Tightening torque

MD332687 or

MD365876

MB991828 or

equivalent

Approximately 3/4 turn [16 ±

4 N·m (12 ± 3 ft-lb)]

MD360935

MB991396 or

equivalent

Approximately one turn [14 ±

2 N·m (124 ± 18 in-lb)]

8.

Install the drain plug and refill engine oil (Refer to P.12-4).

9.

Rev the engine a few times, and check to be sure that no

engine oil leaks at the oil filter.

ENGINE OIL PRESSURE CHECK

M11201000023USA0000010000

1.

Check engine oil quantity.

ENGINE LUBRICATION

12-5

ON-VEHICLE SERVICE