Mitsubishi Outlander XL. Manual - part 189

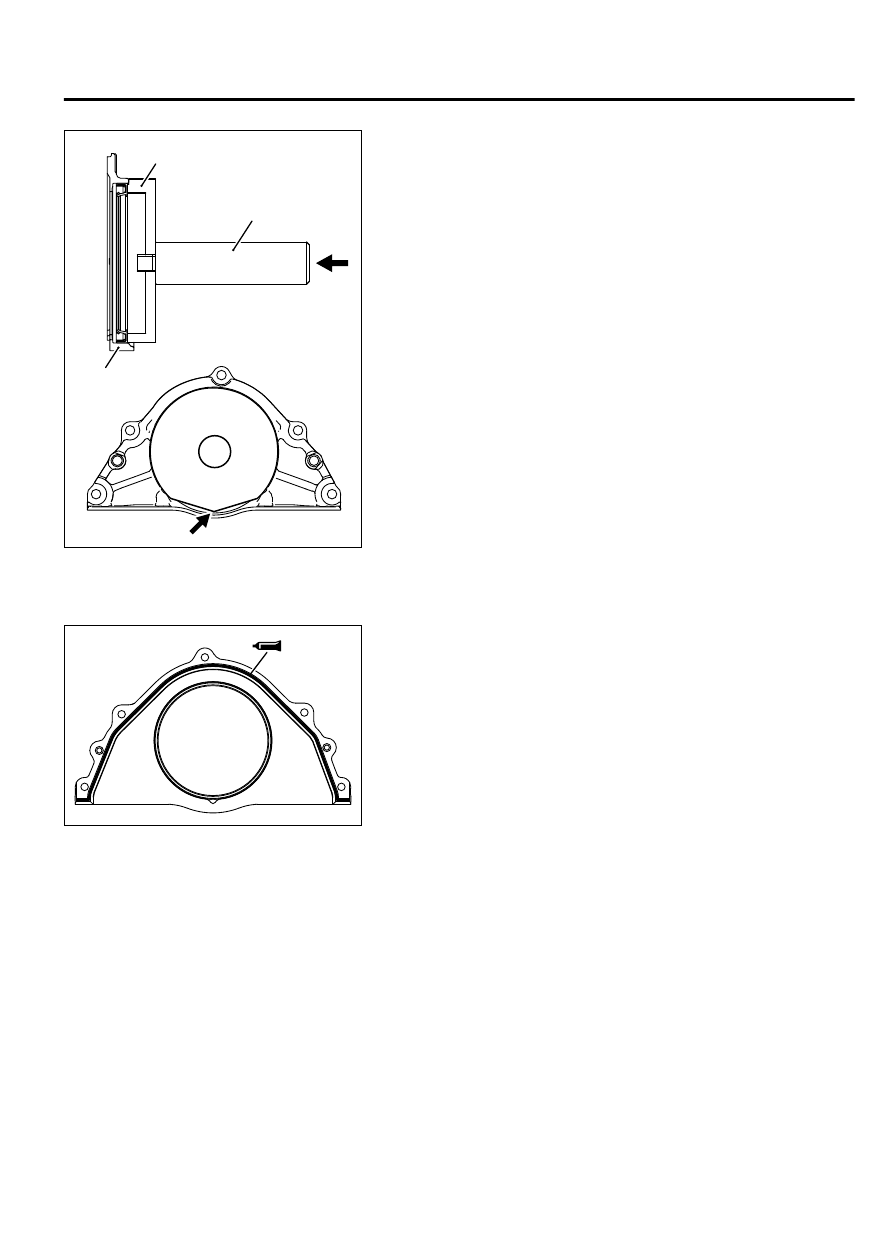

>>F<< CRANKSHAFT REAR OIL SEAL INSTALLATION

ZK600653

MB992183

Oil seal

case

MB992075

0000

Edge

Using special tools MB992075 and MB992183, press-fit a new

crankshaft rear oil seal into the oil seal case.

NOTE:

Put the edge position in place as shown in the

illustration.

>>G<< OIL SEAL CASE INSTALLATION

ZK602461AA00

1.

Apply a 2.5 ± 0.5 mm (0.10 ± 0.01 inch) diameter bead of

sealant (Three bond 1227D [MZ100792] or equivalent) to the

oil seal case.

2.

Apply a small amount of engine oil to the entire circumference

of the oil seal lip section, and place the oil seal case on the

cylinder block.

NOTE:

Install the oil seal case within 15 minutes after

applying liquid gasket.

NOTE:

Then wait at least one hour. Never start the engine

or let engine oil or coolant touch the adhesion surface

during that time.

>>H<< DRIVE PLATE BOLT INSTALLATION

1.

Cleanly remove sealant, oil and dust on the drive plate bolt,

the drive plate and the threaded portions of the crankshaft.

ENGINE OVERHAUL

11B-75

CRANKSHAFT AND CYLINDER BLOCK