Mitsubishi Outlander XL. Manual - part 188

Required Special Tools:

⦆

MB992075: Handle

⦆

MB992183: Crankshaft Rear Oil Seal Installer

⦆

MD998781: Flywheel Stopper

REMOVAL SERVICE POINT

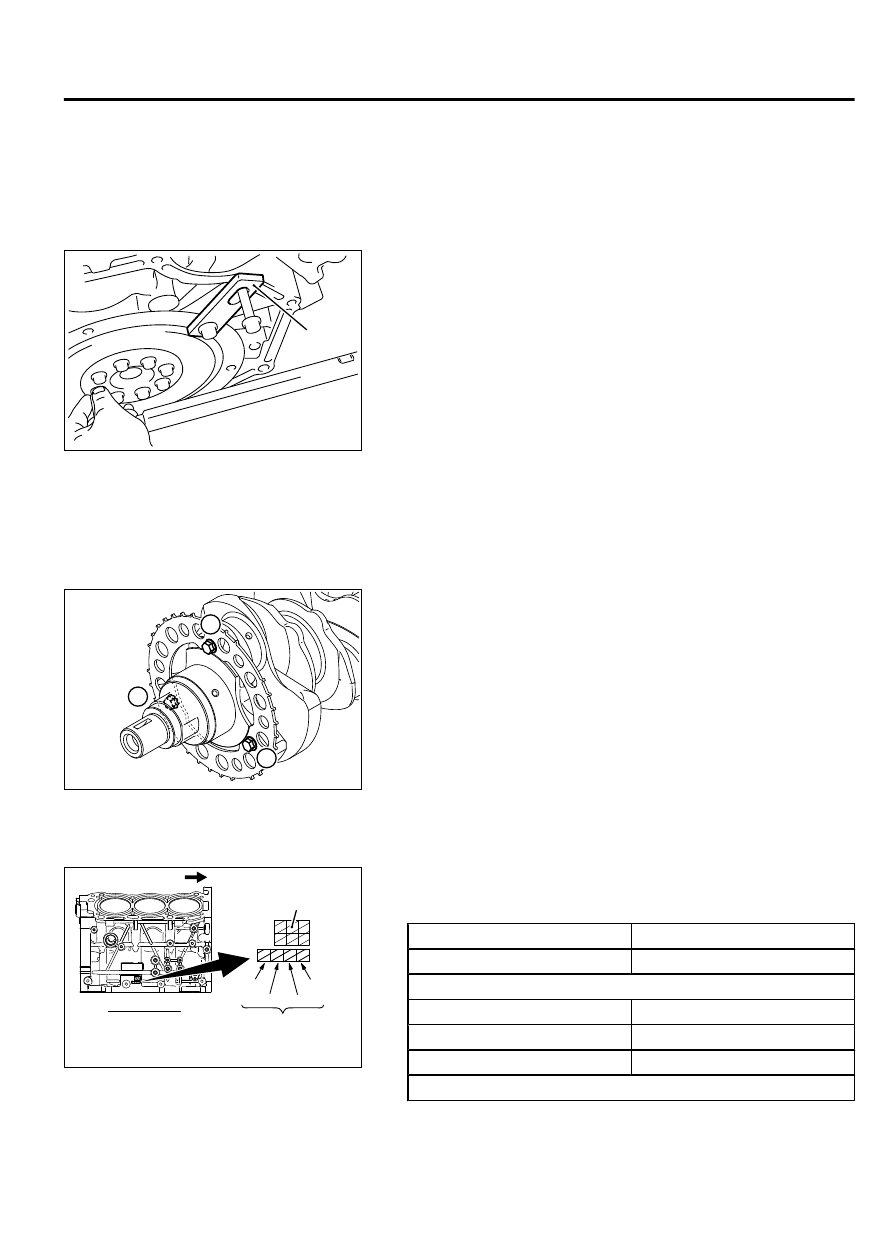

<<A>> DRIVE PLATE BOLT REMOVAL

ZK602109AA00

MD998781

1.

Using special tool MD998781, hold the drive plate.

2.

Remove the drive plate bolt.

INSTALLATION SERVICE POINTS

>>A<< CRANKSHAFT SENSING RING INSTALLATION

1.

Apply the engine oil to the thread portions and the sealed

portions on the installation bolts.

ZK6006540000

1

2

3

2.

In accordance with the tightening order shown in the

illustration, tighten the crankshaft sensing ring to the specified

torque.

Tightening torque: 12 ± 2 N·m (106 ± 17 in-lb)

>>B<< CRANKSHAFT BEARING UPPER INSTALLATION

ZK600656

No.4

Cylinder

bore size

No.3 No.2

No.1

0000

Right side

Timing belt side

Crankshaft journal (Upper)

identification mark

1.

If the upper crankshaft bearing is replaced, select based on

the identification mark of cylinder block (illustrated) and the

table shown below.

Crankshaft journal (Upper) Crankshaft bearing

Identification mark

Identification mark

Number 1 and 4 journal

1

1

2

2

3

3

Number 2 and 3 journal

ENGINE OVERHAUL

11B-71

CRANKSHAFT AND CYLINDER BLOCK