Mitsubishi Outlander XL. Manual - part 186

REMOVAL SERVICE POINTS

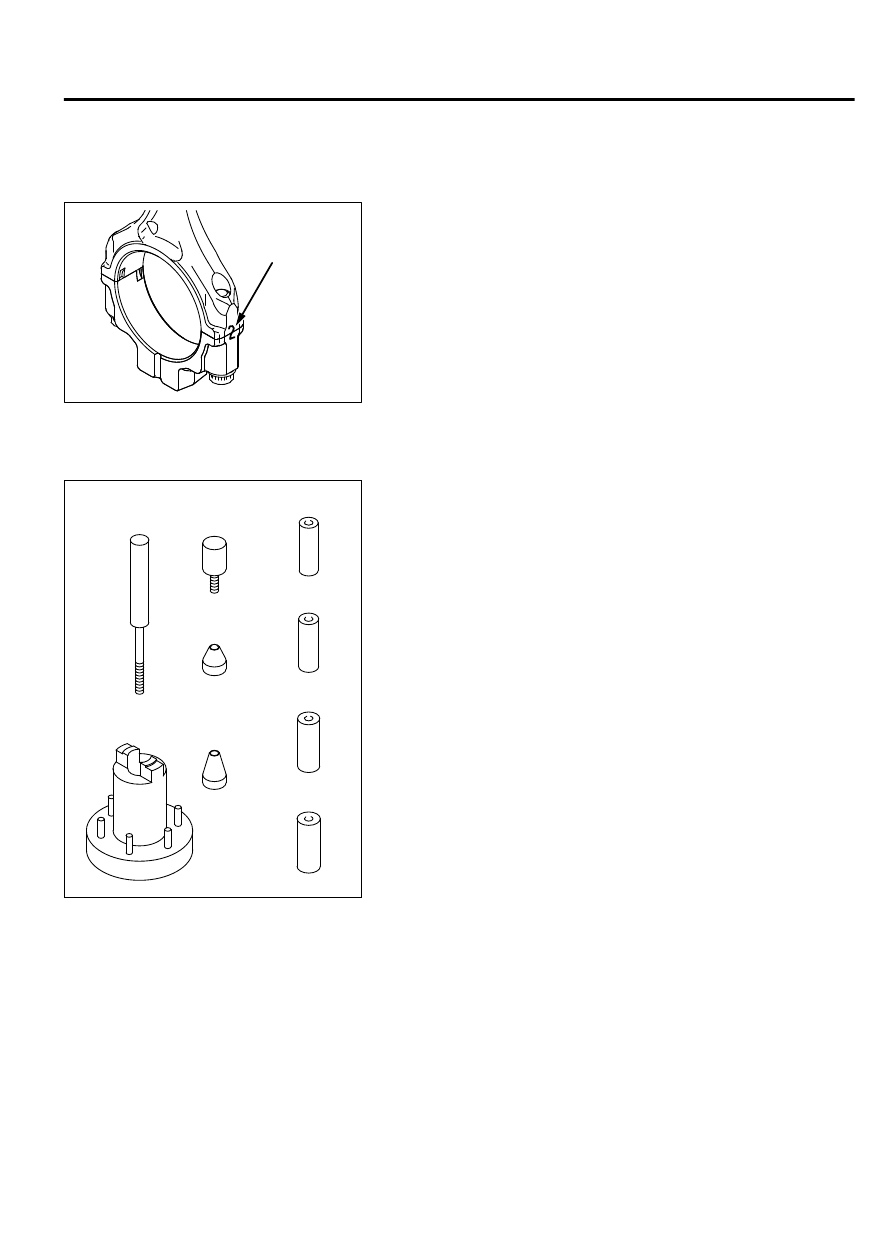

<<A>> CONNECTING ROD CAP REMOVAL

ZK602114

Cylinder number

0000

1.

Mark the cylinder number on the side of the connecting rod

big end for correct reassembly.

2.

Keep the removed connecting rods, caps, and bearings in

order according to the cylinder number.

<<B>> PISTON PIN REMOVAL

ZK602503AA00

Guide A:

21.9 mm (0.86 in)

Guide A:

20.9 mm (0.82 in)

Guide A:

18.9 mm (0.74 in)

Guide A:

17.9 mm (0.70 in)

Guide B

Guide C

Guide D

(MB991659)

Base

Push rod

MD998780

1.

The special tool MD998780 consists of the elements shown in

the illustration.

2.

When removing the piston pin, the special tool MB991659 is

also used.

ENGINE OVERHAUL

11B-63

PISTON AND CONNECTING ROD