Mitsubishi Outlander XL. Manual - part 176

ZK6019170000

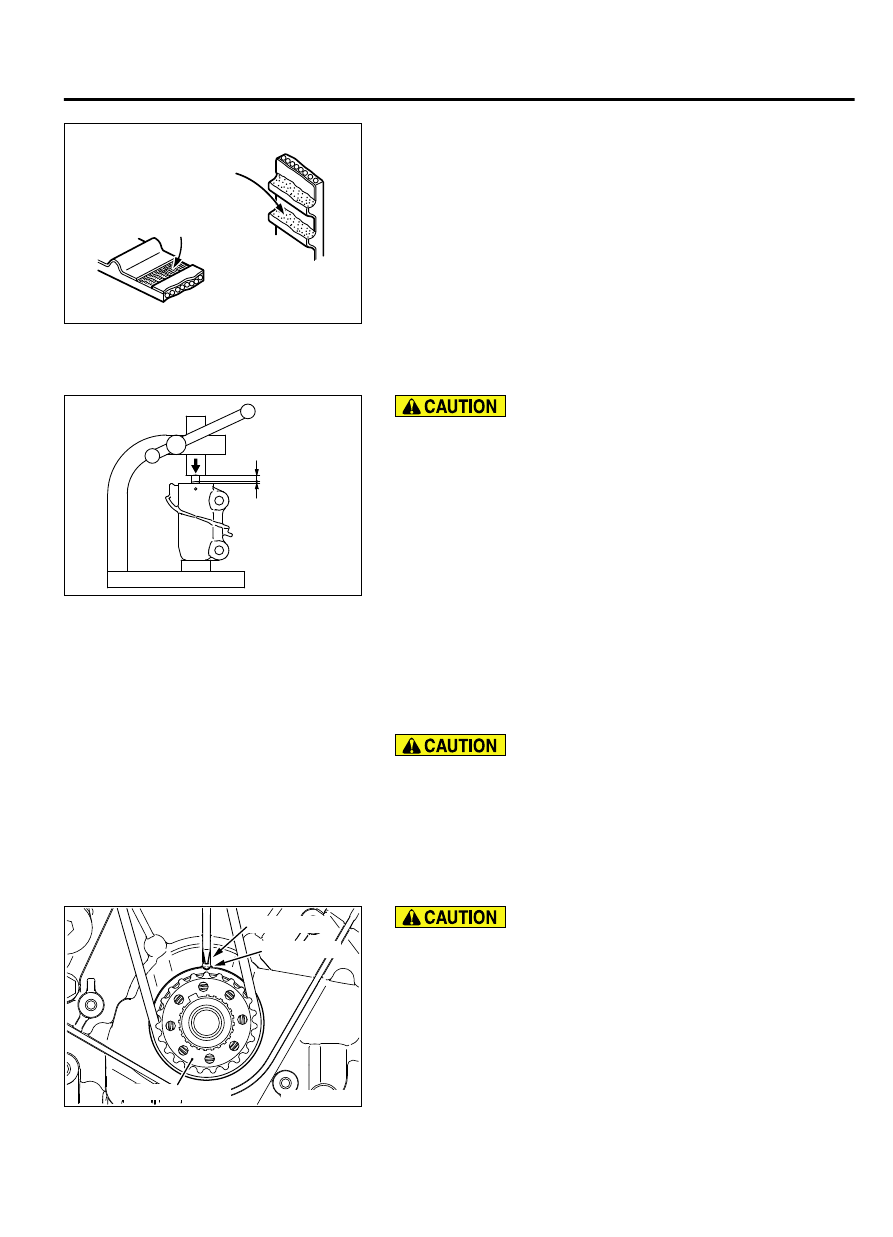

Missing

tooth

Canvas lost and

rubber exposed

7.

Abnormal wear on teeth.

Initial stage:

Canvas worn (fluffy canvas fibers, rubbery texture

gone, white discoloration, canvas texture indistinct)

Final stage:

Canvas worn, exposing rubber (tooth width reduced)

8.

Missing tooth.

AIR BLEEDING METHOD

M11103000952USA0000010000

ZK600050

A: 3 mm

(0.12 in)

B: 11.4 mm

(0.45 in)

0000

100 to 200 N

(22 to 44 lb)

Upright

stance

⦆

Always use the vertical press and put the auto-tensioner

vertically.

⦆

For breakage prevention, Do not apply the load of 5,000

N (1,124 pound) or more to the rod.

⦆

Do not press the rod beyond Dimension "A" shown in the

illustration.

1.

Set the auto tensioner as shown in the illustration.

2.

Press the rod slowly down to the lowest point "A" shown in the

illustration.

3.

Repeat the procedure 2 three times.

4.

While the rod is projected at the point "B" shown in the

illustration, push the rod with 100 - 200 N (22 - 44 pound).

Check the enough stiffness. If the stiffness is not enough,

replace the auto tensioner.

5.

Press the rod slowly down. Put the pin through the hole and

fix it.

After the air bleeding operation has been completed, do not

tilt the auto-tensioner to 60° or more from the right angle

position.

VALVE CLEARANCE ADJUSTMENT

M11103000917USA0000010000

1.

Remove the rocker cover and ignition coil.

ZK6000560000

Timing mark

Timing mark

Camshaft sprocket

Rotate the crankshaft clockwise at any time.

2.

Turn the crankshaft clockwise, and align the crankshaft

sprocket timing mark with the position shown in the illustration.

ENGINE OVERHAUL

11B-23

TIMING BELT