Mitsubishi Outlander XL. Manual - part 175

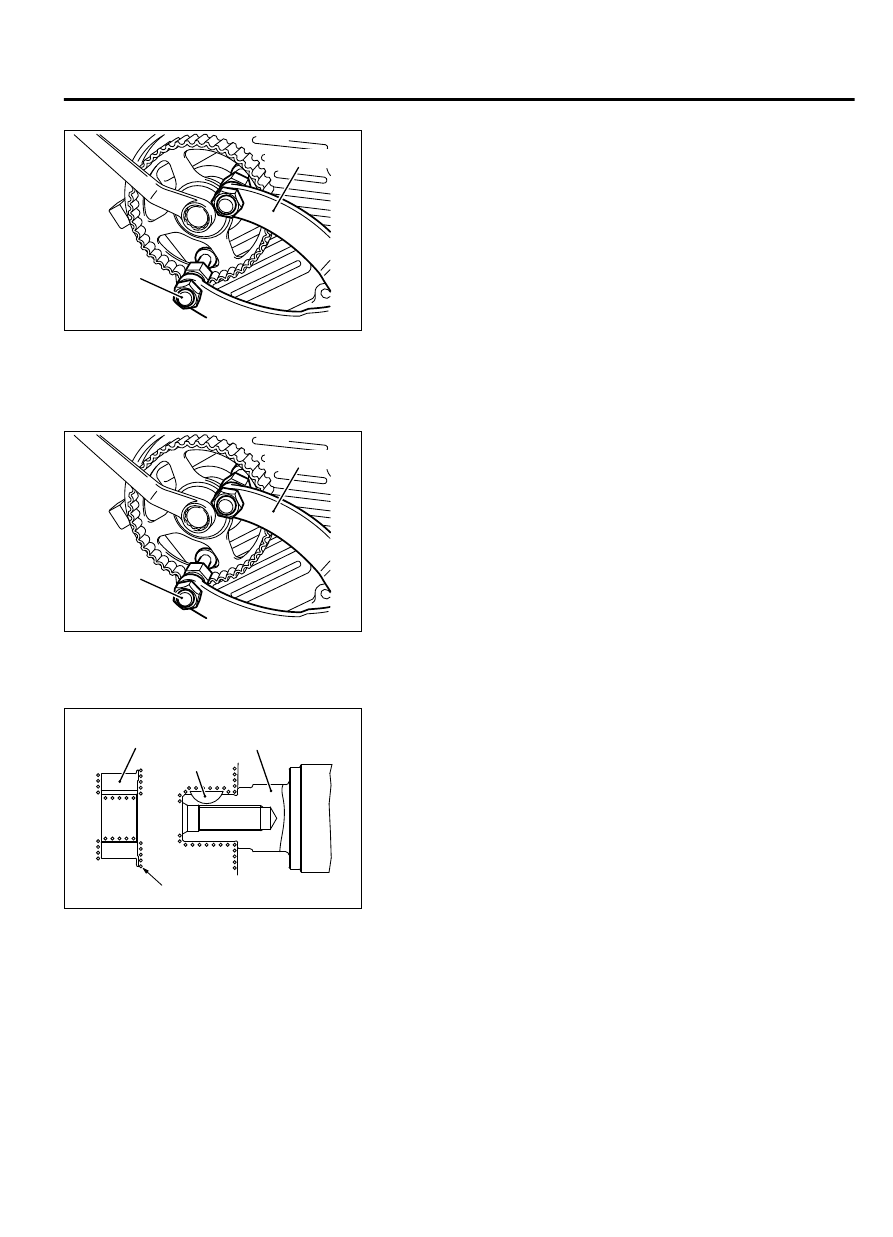

<<D>> CAMSHAFT SPROCKET BOLT REMOVAL

ZK602101AA00

MB990767

MD998719

Use special tools MB990767 and MD998719 to prevent the

camshaft sprocket from turning, and then loosen the camshaft

sprocket bolt.

INSTALLATION SERVICE POINTS

>>A<< CAMSHAFT SPROCKET BOLT INSTALLATION

ZK602101AA00

MB990767

MD998719

Use special tools MB990767 and MD998719 to prevent the

camshaft sprocket from turning, and then tighten the camshaft

sprocket bolt.

Tightening torque: 90 ± 10 N·m (65 ± 7 ft-lb)

>>B<< CRANKSHAFT SPROCKET INSTALLATION

ZK600044

Crankshaft

Crankshaft

sprocket

Clean

0000

Key

1.

Clean the hole in the crankshaft sprocket.

2.

Clean and degrease the mating surfaces of the crankshaft

sprocket.

NOTE:

Degreasing is necessary to prevent decrease in

friction on the mating surfaces.

3.

Install the crankshaft sprocket to the crankshaft.

ENGINE OVERHAUL

11B-19

TIMING BELT