Mitsubishi Outlander XL. Manual - part 173

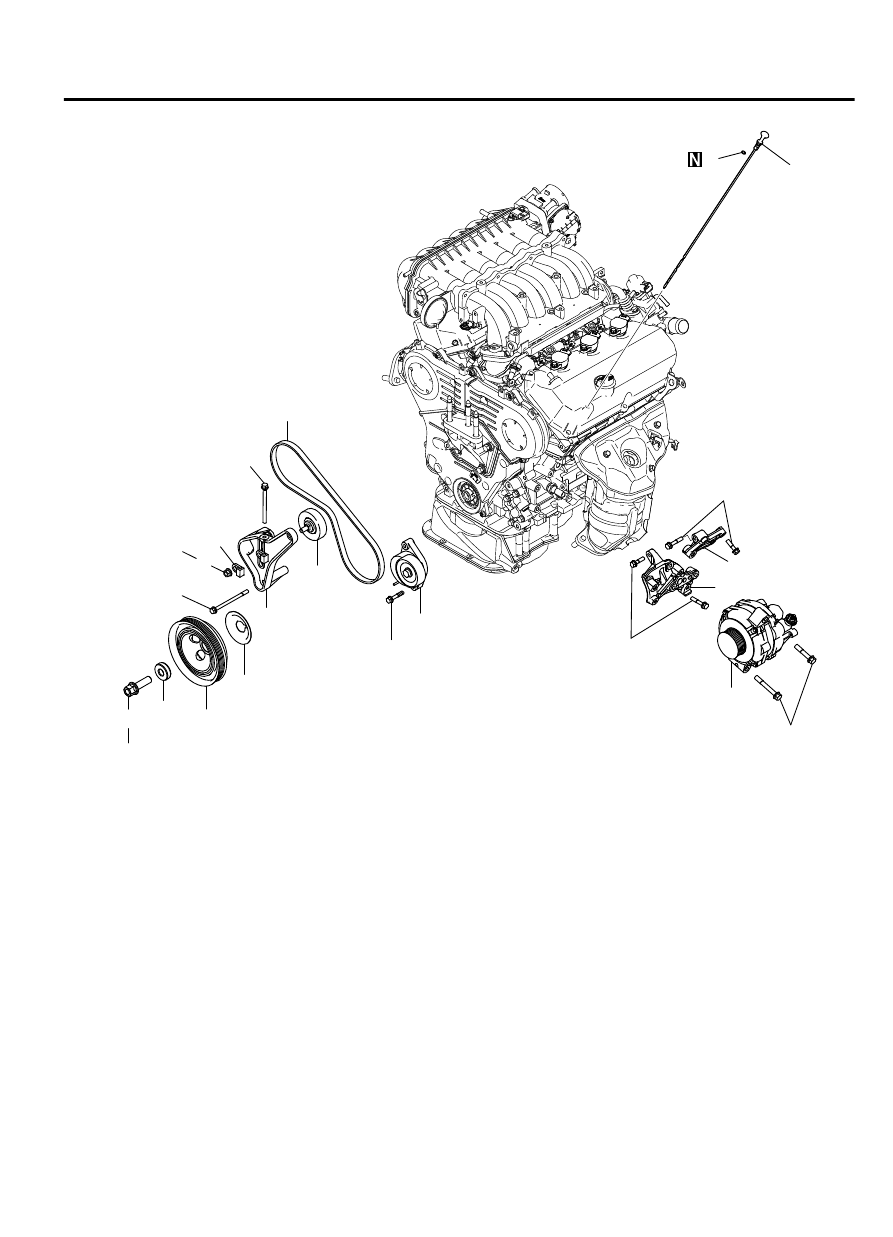

ZK600041

23 ± 6 N·m

17 ± 4 ft-lb

1

3

4

5

6

7

8

9

10

11

12

13

16

15

47 ± 11 N·m

35 ± 7 ft-lb

200 N·m

148 ft-lb

0 N·m

0 ft-lb

23 ± 6 N·m

17 ± 4 ft-lb

23 ± 6 N·m

17 ± 4 ft-lb

47 ± 11 N·m

35 ± 7 ft-lb

2

23 ± 6 N·m

17 ± 4 ft-lb

14

AA01

→

→

110 N·m

81 ft-lb

→

+60°

Removal steps

1.

OIL DIPSTICK

2.

O-RING

3.

DRIVE BELT

<<A>>

>>B<<

4.

CRANKSHAFT BOLT

5.

CRANKSHAFT PULLEY WASHER

6.

CRANKSHAFT PULLEY

7.

FRONT FLANGE

8.

FLANGE NUT

9.

ADJUSTING NUT

Removal steps

10. FLANGE BOLT

11. TENSIONER PULLEY

12. POWER

STEERING

TENSIONER

PULLEY BRACKET

13. DRIVE BELT AUTO TENSIONER

>>A<<

14. GENERATOR

15. GENERATOR BRACKET UPPER

16. GENERATOR BRACKET LOWER

Required Special Tool:

⦆

MD998781: Flywheel Stopper

ENGINE OVERHAUL

11B-11

GENERATOR