Mitsubishi Outlander XL. Manual - part 166

INSTALLATION SERVICE POINTS

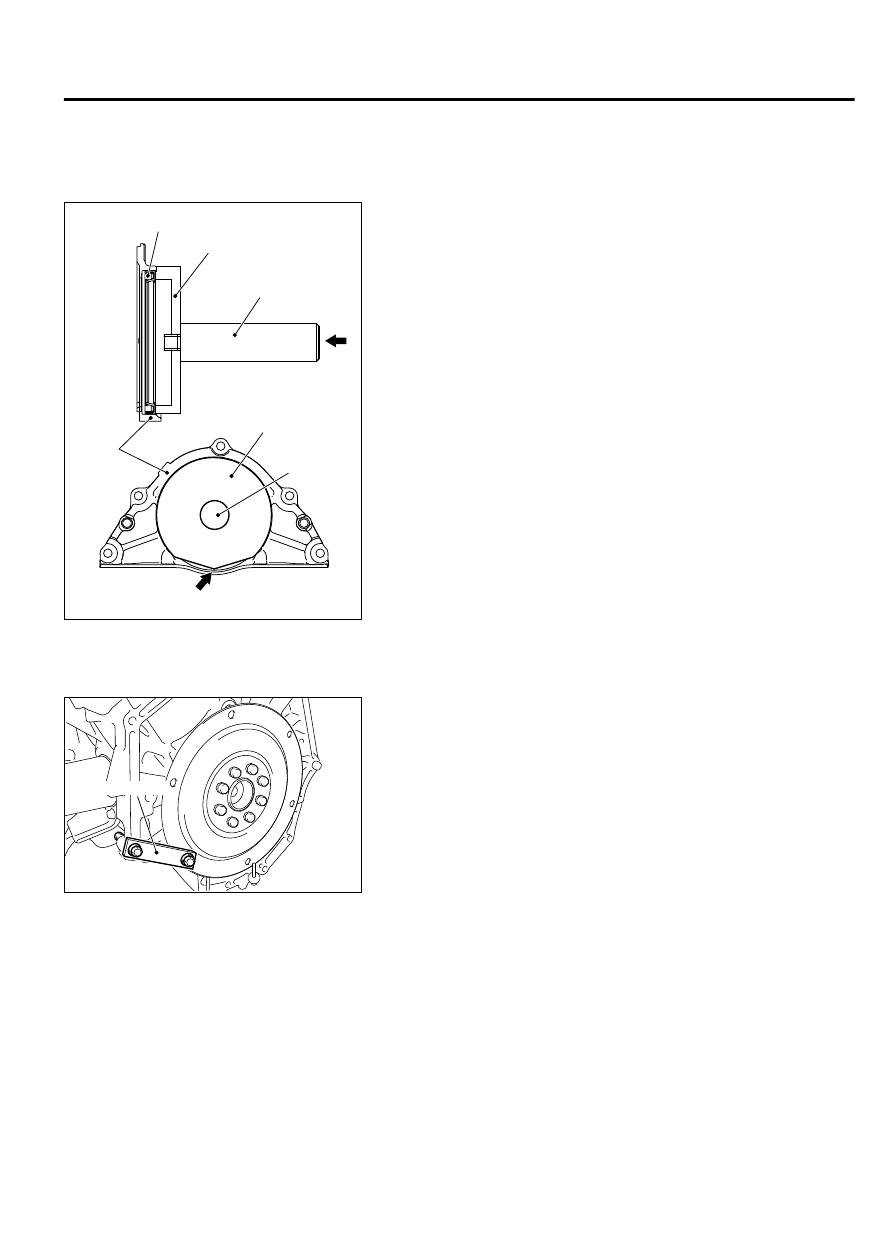

>>A<< CRANKSHAFT REAR OIL SEAL INSTALLATION

ZC603634

Edge

Oil seal

MB992183

MB992075

MB992183

Oil seal

case

AA00

MB992075

Use special tool MB992075 and MB992183, press-fit a new

crankshaft rear oil seal into the oil seal case.

>>B<< DRIVE PLATE BOLTS INSTALLATION

ZC6017630000

MD998781

1.

Use special tool MD998781 to secure the drive plate in the

same manner as removal.

2.

Tighten the drive plate bolts to the specified torque.

Tightening torque: 74 ± 1 N·m (54 ± 1 ft-lb)

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

M11102000040USA0000010001

Pre-removal and Post-installation Operation

⦆

Intake Manifold Removal and Installation (Refer to GROUP 15, Intake Manifold P.15-8).

⦆

Exhaust Manifold Removal and Installation (Refer to GROUP 15, Exhaust Manifold P.15-11).

⦆

Timing Belt Removal and Installation (Refer to P.11A-49).

⦆

Thermostat Housing Removal and Installation (Refer to GROUP 14, Water Hose and Water Pipe P.14-23).

ENGINE MECHANICAL

11A-45

CYLINDER HEAD GASKET