Content .. 1206 1207 1208 1209 ..

Mitsubishi Outlander XL. Manual - part 1208

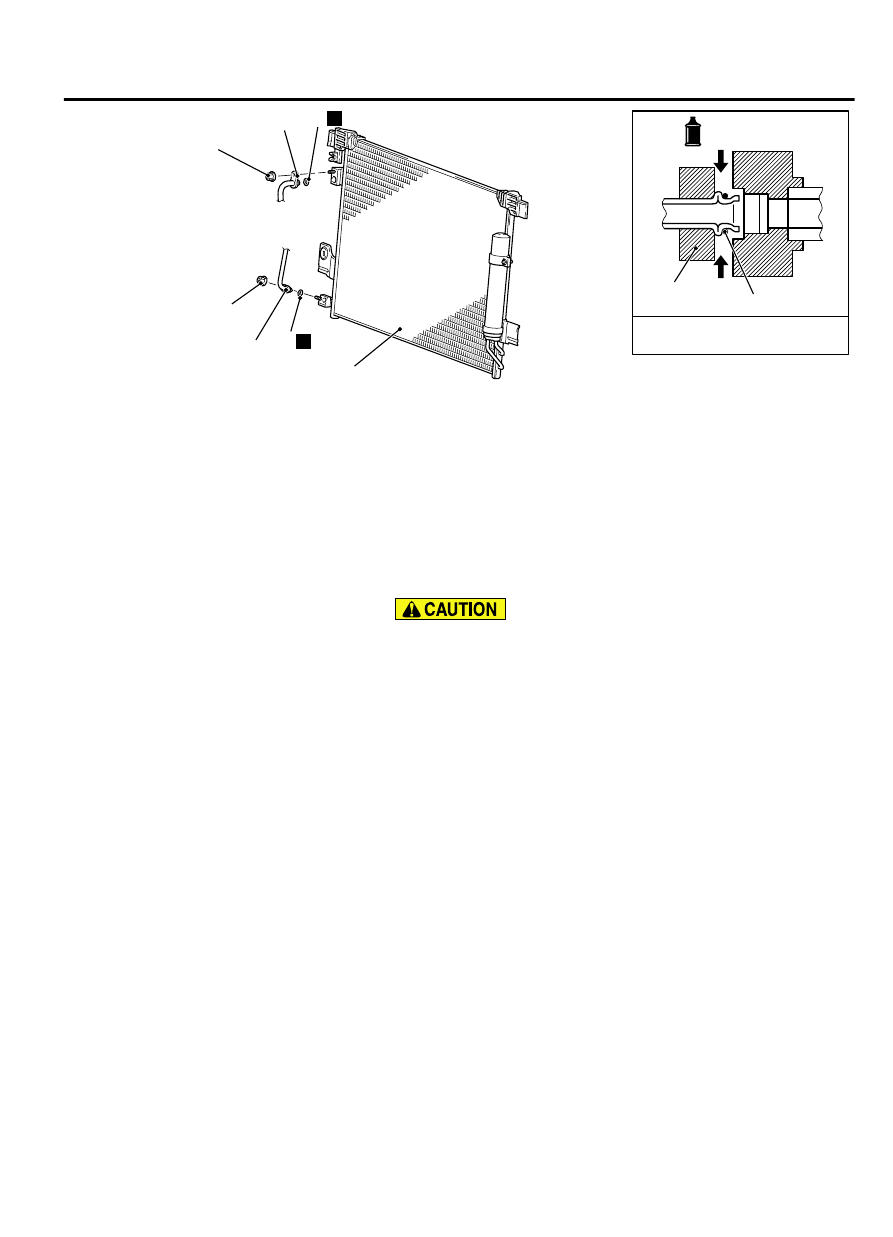

ZC6020480000

2

1

4

4.9 ± 0.9 N·m

43 ± 8 in-lb

1, 2

3

3

N

3

N

-Pipe coupling

A/C compressor oil:

SUN PAG 56

4.9 ± 0.9 N·m

43 ± 8 in-lb

Condenser removal steps

<<A>>

1.

Flexible discharge hose connection

<<A>>

2.

Liquid pipe A connection

3.

O-ring

Condenser removal steps

·

Front under cover

4.

Condenser assembly

REMOVAL SERVICE POINTS

<<A>> FLEXIBLE DISCHARGE HOSE AND LIQUID PIPE A

DISCONNECTION

As the compressor oil and receiver are highly moisture

absorbent, use a non-porous material to plug the hose and

nipples.

To prevent the entry of dust or other foreign bodies, plug the

dismantled hose and condenser assembly nipples.

INSTALLATION SERVICE POINT

>>A<< CONDENSER INSTALLATION

When replacing the condenser, refill it with a specified amount

of compressor oil and install it to the vehicle.

Compressor oil: SUN PAG 56

Quantity: 15 cm3(0.5 fl.oz)

REFRIGERANT LINE

REMOVAL AND INSTALLATION

M15502000064USA0000010000

Pre-removal and Post-installation Operation

⦆

Refrigerant Draining and Refilling (Refer to Charging and Discharging P.55A-125).

AIR CONDITIONING

55A-123

REFRIGERANT LINE