Mitsubishi Outlander XL. Manual - part 26

ZB6001100000

4.

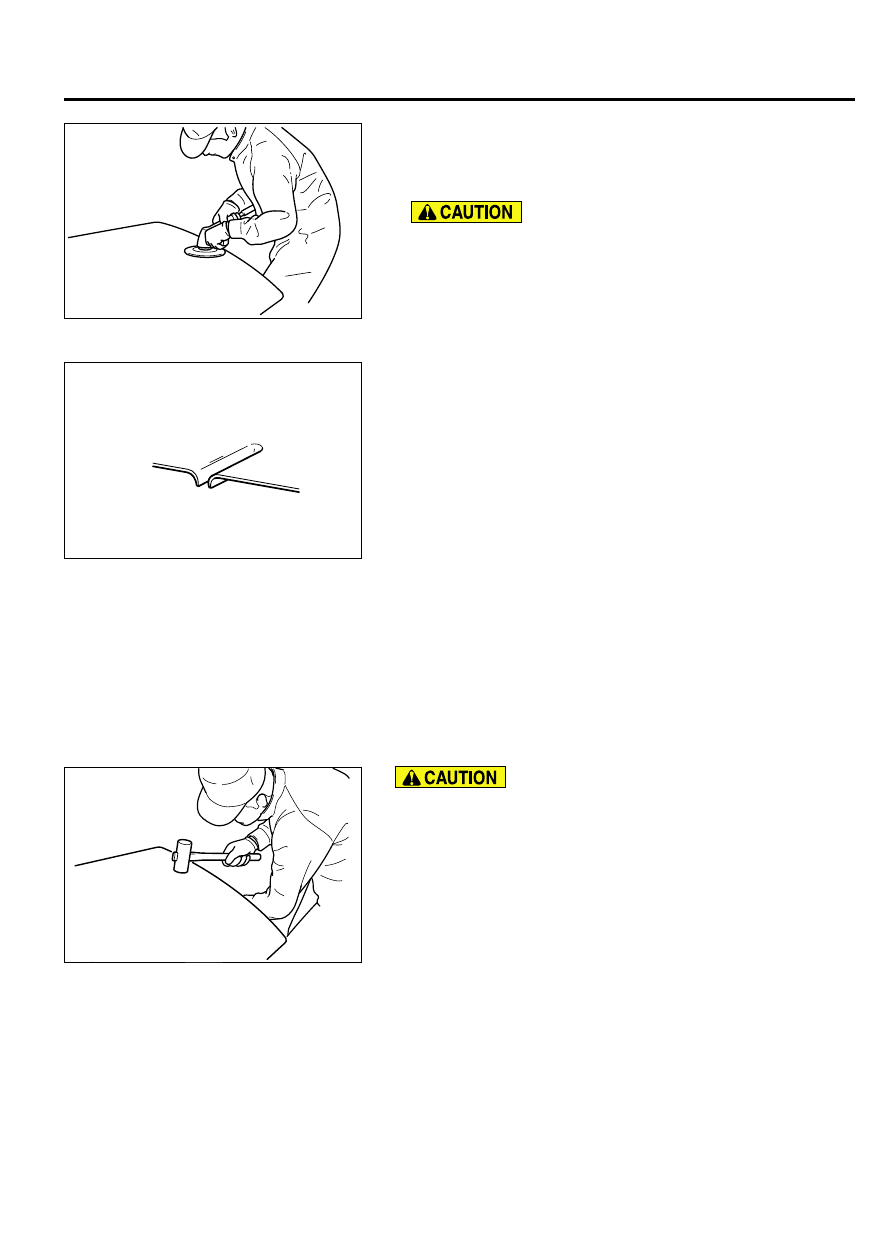

Sanding: Grind the surface with a disk sander or a double-

action sander.

⦆

Disk sander: #100 to #120

⦆

Double-action sander: #150 to #180

Aluminum plates are softer than steel sheets, therefore

select an appropriate abrasive to prevent the surface from

deeply scratched. The heating temperature should be

approximately 250°C (482°F).

Correction of cuts and cracks

ZB6001210000

If cuts, cracks, or holes occur in a steel sheet panel, MIG welding

with CO2is used for repair. However, for an aluminum panel, use

MIG or TIG welding with argon gas (inert gas) as shielding gas

for repair.

DEGREE OF DISTORTION CAUSED BY WELDING

Gas welding (a large amount of distortion) TIG welding MIG

welding (a small amount of welding). This manual explains the

operation procedure of MIG welding which causes a small

amount of distortion by welding heat.

Operation procedure of MIG welding

ZB600118

0000

⦆

Be careful to avoid excessive stretch of or damage to the

panel.

⦆

Minimize the gap of the butt joint.

1.

Correct the damaged area by hammering lightly while heating

it. If any area is stretched by hammering, grind it off with a

pneumatic saw.

WELDED PANEL REPLACEMENT

3-53

ALUMINUM PANEL