Mitsubishi Outlander XL. Manual - part 18

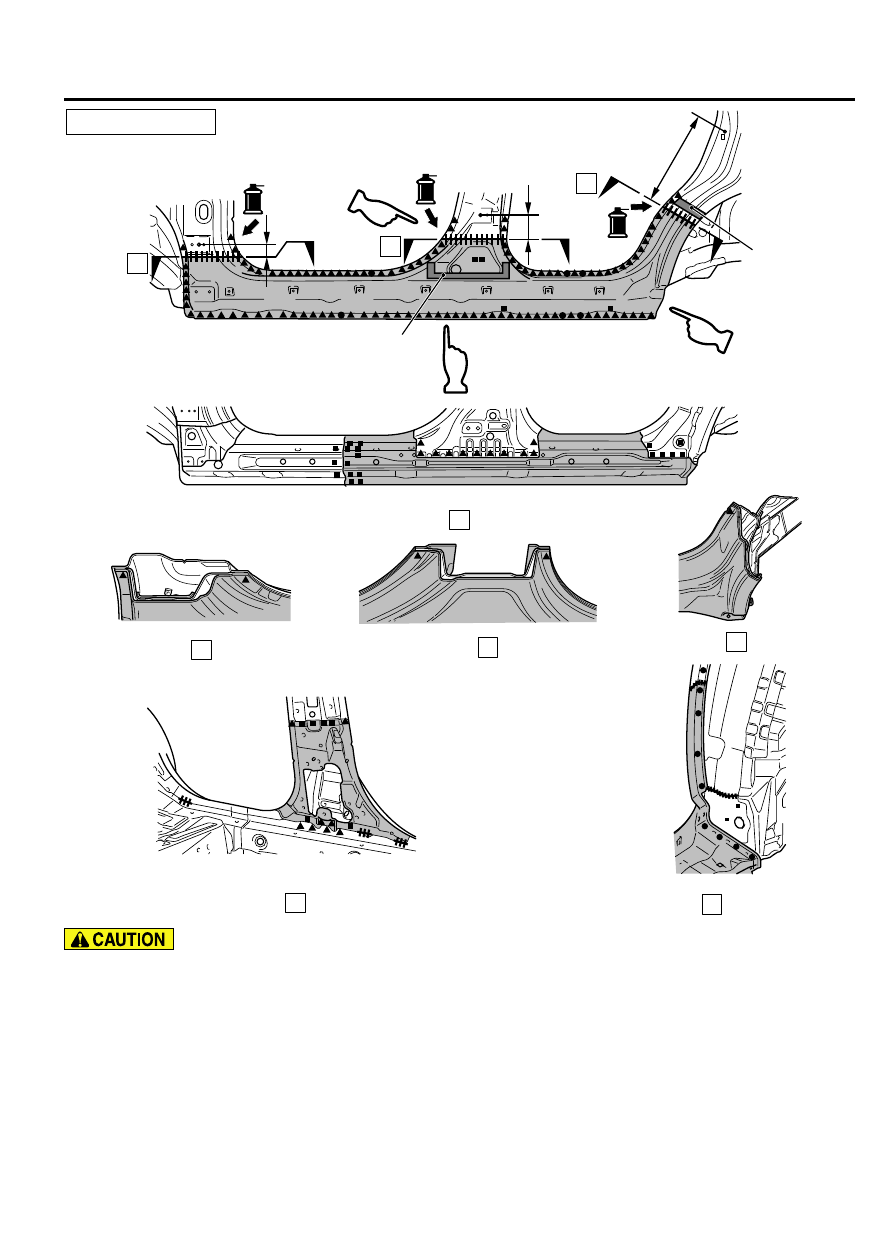

ZB600075

F

A

B

C

F

0000

A

REPAIR WELDS

Acoustic foam

(With the side outer panel removed)

Acoustic foam

50 mm

(1.97 in)

50 mm

(1.97 in)

260 mm

(10.2 in)

B

C

D

E

F

D

When repairing the area using foam materials do

not use firing tools since the foaming materials

may burn.

WELDED PANEL REPLACEMENT

3-21

SIDE SILL