Mitsubishi Outlander XL. Manual - part 17

ZB600347 0000

: Body sealant

4.

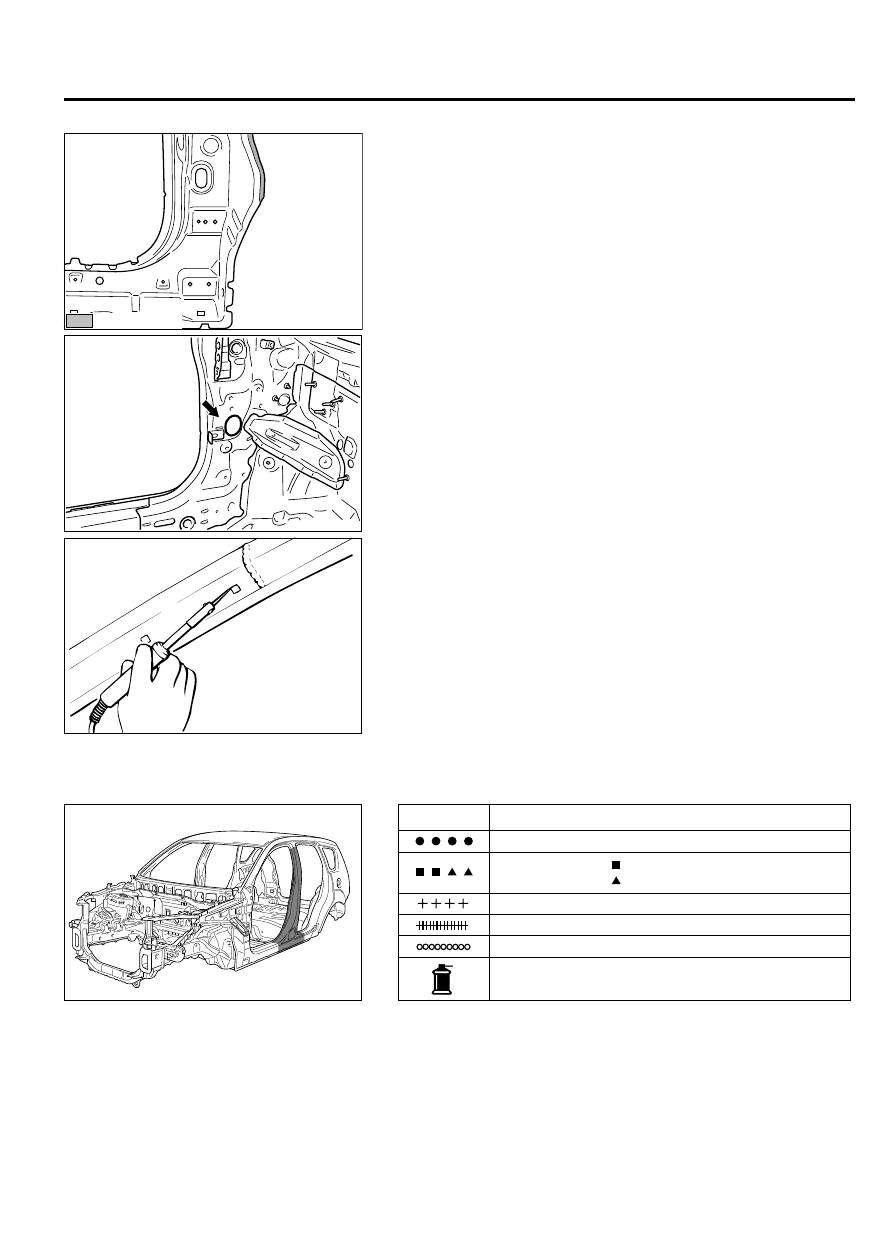

When installing the front pillar outer, apply body sealant as

shown in the figure.

ZB600138 0000

5.

After installing the front pillar outer, seal the hole and flange

with bolt and aluminum tape, and then fill the hole with foam

materials as shown in the figure.

Foam : 3M™ AAD ULTRAPRO Panel foam-Yellow

ZB600112 0001

6.

Wait 2 hours after filling the foam materials to remove the bolt

and aluminum tape, then melt the foam materials with a

soldering gun to ensure that a clip, etc. can be inserted in the

hole filled with foam materials

CENTER PILLAR

M40300000060USA0000010000

ZB600148 0000

( )

Symbol

Operation description

Spot welding

MIG plug welding

indicates two panels to be welded

indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent applications locations

(Use access holes to apply liberally to butt-welded joints.)

WELDED PANEL REPLACEMENT

3-17

CENTER PILLAR