Mitsubishi Outlander GS45X. Manual - part 504

CYLINDER HEAD GASKET

TSB Revision

ENGINE MECHANICAL <3.0L ENGINE>

11C-53

INSTALLATION SERVICE POINTS

.

>>A<< CYLINDER HEAD ASSEMBLY INSTALLA-

TION

CAUTION

Be careful that no foreign material gets into the cylinder,

coolant passages or oil passages. Engine damage may

result.

1. Use a scraper to clean the gasket surface of the cylinder

head assembly.

2. Check in the following procedure before reusing the cylinder

head bolt.

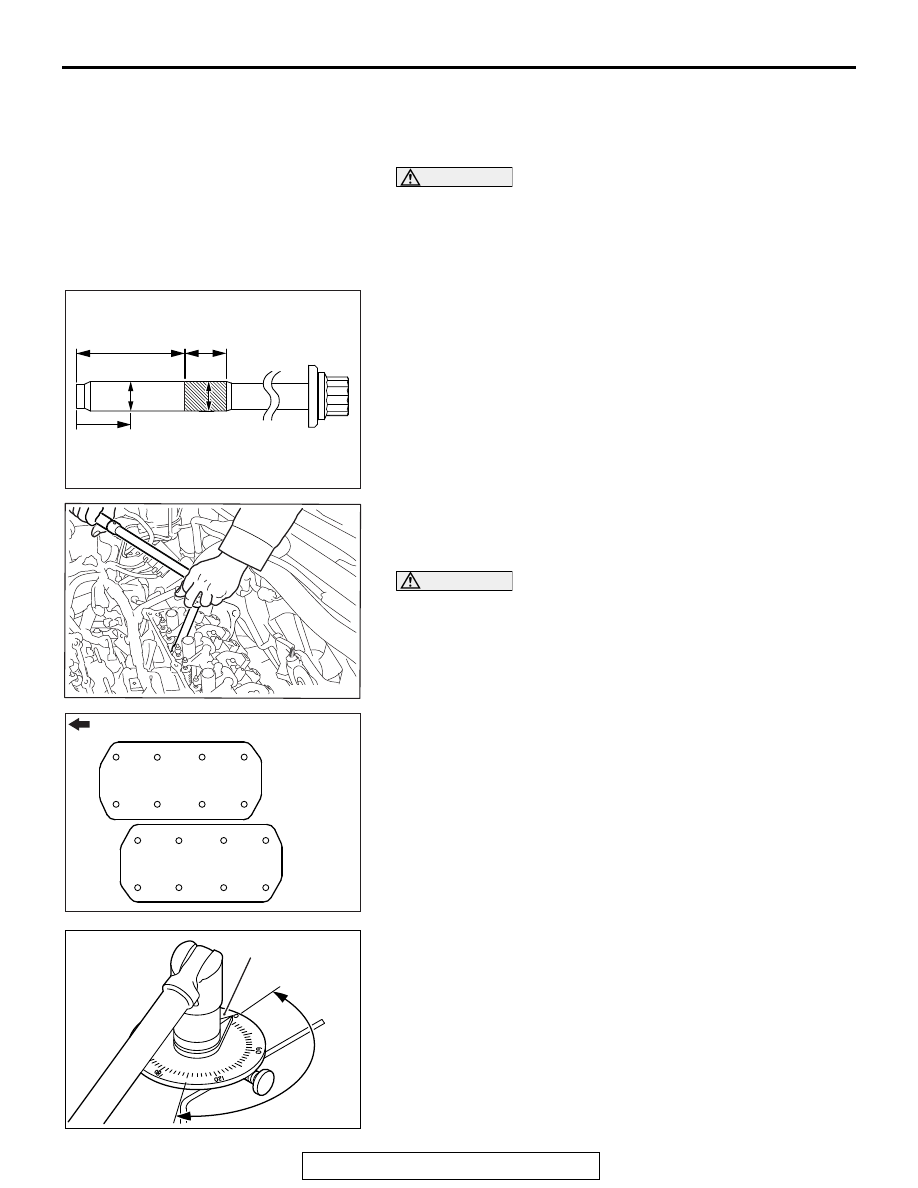

(1) Measure the outside diameter "A".

(2) Measure the smallest outside diameter "B" within the

range "X" shown in the illustration.

(3) If the difference of outside diameter of thread exceeds

the limit, replace the cylinder head bolt.

Limit: 0.1mm (0.0039 inch)

3. Tighten the bolts to the specified torque in the order shown

in the illustration. (in two or three cycles)

Tightening torque: 45

± 2 N⋅m (33 ± 1 ft-lb)

CAUTION

• If the bolt is turned less than 150 to 154 degrees, proper

fastening performance may not be achieved. Be sure to

turn the bolt exactly 150 to 154 degrees.

• If the bolt is overtightened, loosen the bolt completely

and then retighten it by repeating the tightening proce-

dure from step 1.

4. Using special tool MB991614, tighten the cylinder head bolt

another 150 to 154 degrees.

AK700001AB

34 mm

(1.34 in)

17 mm

(0.67 in)

A

B

B

X

AC703060AB

AC703072

Engine front

<Right

bank>

<Left

bank>

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

AC

AC703073

150˚ to 154˚

MB991614

AB