Mitsubishi Outlander GS45X. Manual - part 502

OIL PAN AND OIL STRAINER

TSB Revision

ENGINE MECHANICAL <3.0L ENGINE>

11C-45

INSTALLATION SERVICE POINTS

.

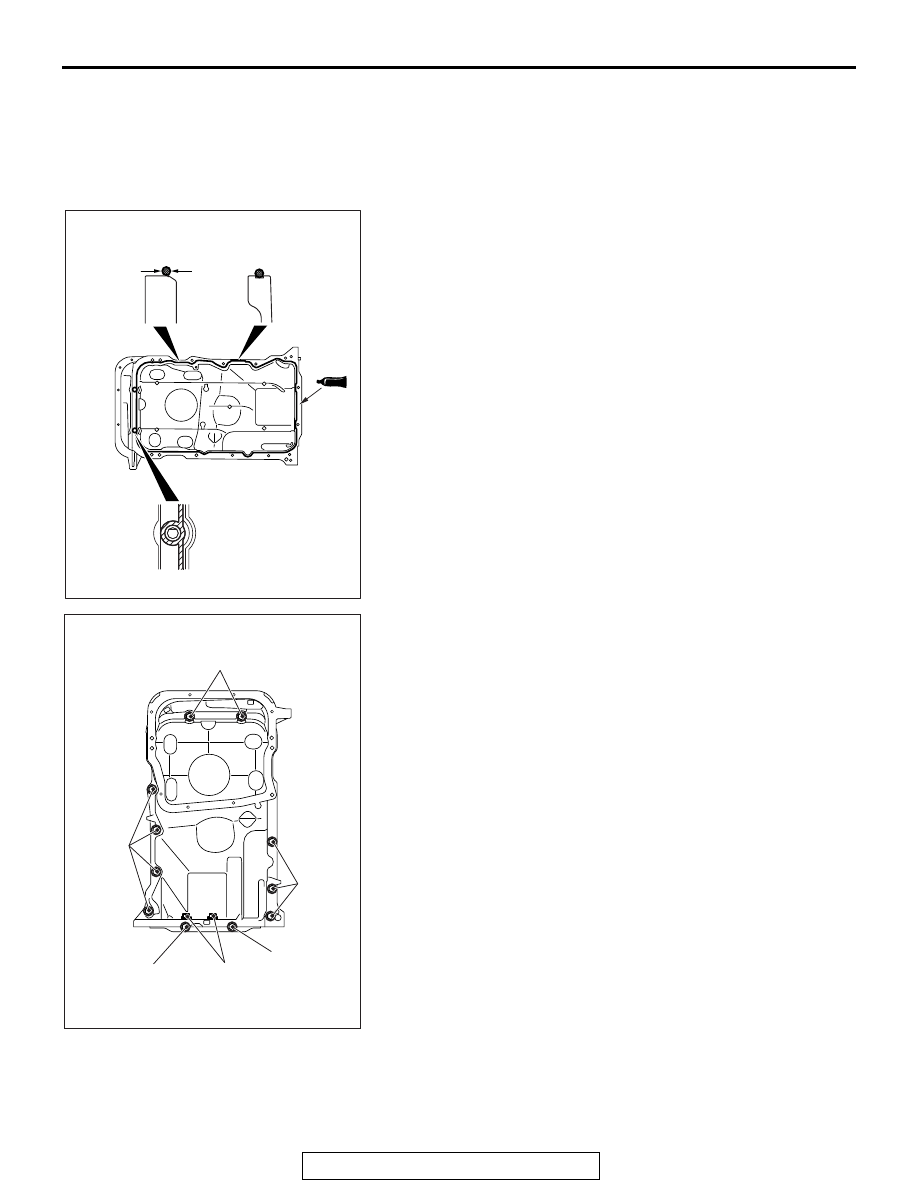

>>A<< ENGINE UPPER OIL PAN/COVER INSTAL-

LATION

1. Remove sealant from the oil pan and cylinder block mating

surfaces.

2. Apply a bead of the sealant to the cylinder block mating

surface of the engine oil pan as shown.

Specified sealant: ThreeBond 1227D or equivalent

NOTE: Install the engine lower oil pan immediately after

applying sealant.

3. Assemble the oil pan to the cylinder block to the engine

upper oil pan.

4. Install the bolts to the engine upper oil pan and cover as

shown, and tighten them to the specified torque.

Tightening torque: 9.5

± 2.5 N⋅m (85 ± 22 in-lb)

.

AC703031

Ø2 mm or Ø3 mm

(Ø0.08 in or Ø0.12 in)

AB

AC703032AB

Bolt specifications

Thread diameter × Length mm

M6 × 20

M6 × 20

M6 × 20

M6 × 10

M6 × 124

M6 × 124