Mitsubishi Outlander GS45X. Manual - part 465

HYDRAULIC UNIT

TSB Revision

ACTIVE STABILITY CONTROL SYSTEM (ASC)

35C-287

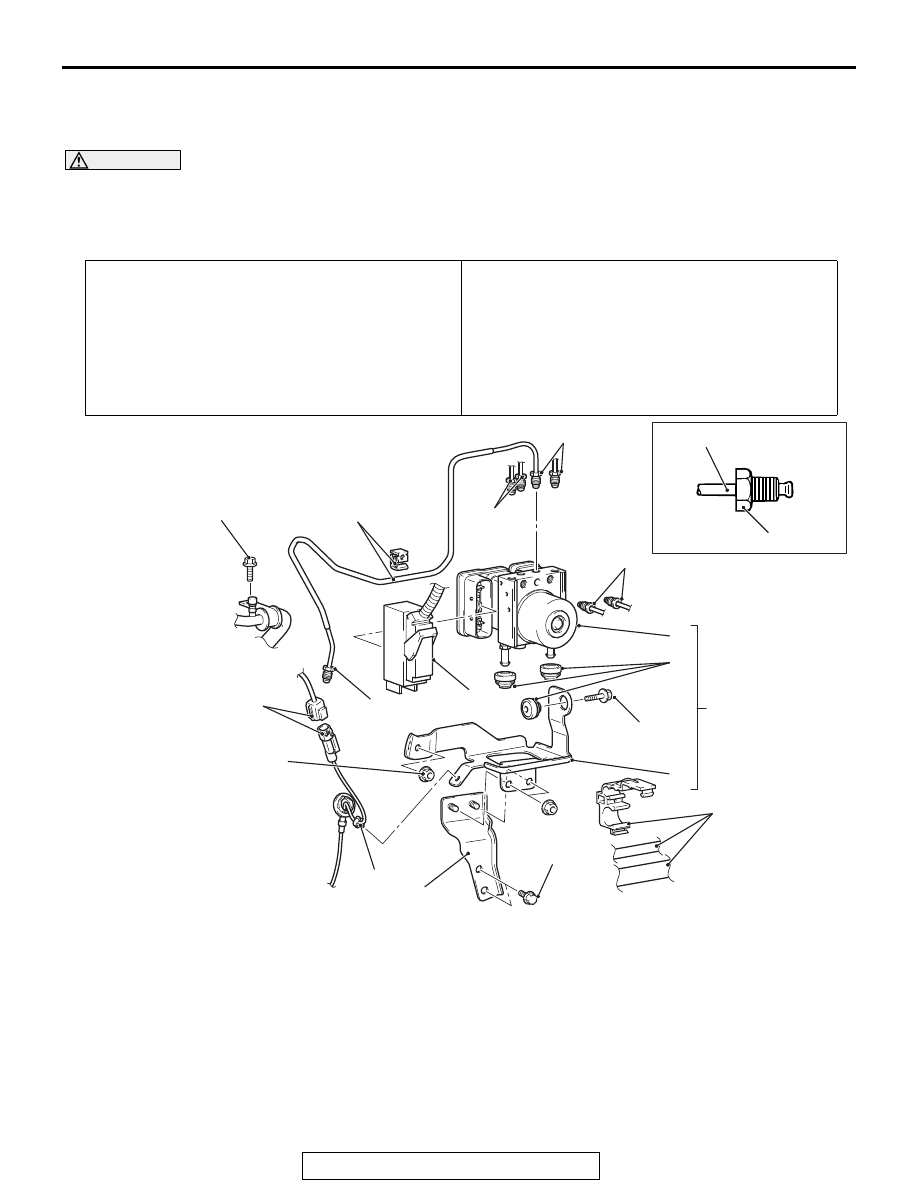

HYDRAULIC UNIT

REMOVAL AND INSTALLATION

M1355005600572

CAUTION

When the hydraulic unit (integrated with ASC-ECU) is replaced, after turning the ignition switch ON or

OFF (vehicle information from ETACS-ECU is registered), always carry out the calibration of all sen-

sors (steering wheel sensor, G and yaw rate sensor, and brake fluid pressure sensor) at one time.(

Refer to

.)

Pre-removal operation

• Strut tower bar removal (Refer to GROUP 42A − Strut

Tower Bar

.)

• Brake fluid draining

• Intake manifold plenum removal (Refer to GROUP 15 −

Intake Manifold Plenum

Post-installation operation

• Intake manifold plenum installation (Refer to GROUP 15 −

Intake Manifold Plenum

• Brake fluid refilling and air bleeding (Refer to GROUP 35A

− On-vehicle Service, Brake Fluid Level Inspection and

Bleeding

• Strut tower bar installation (Refer to GROUP 42A − Strut

Tower Bar

.)

• Hydraulic unit check (Refer to

AC703833 AB

5

1

11

5

10 ± 2 N·m

89 ± 17 in-lb

24 ± 4 N·m

18 ± 3 ft-lb

5

9

12

16 ± 3 N·m

12 ± 2 ft-lb

5

10

13 ± 2 N·m

111 ± 22 in-lb

3

8

4

5

2

6

7

Removal steps

1.

ASC-ECU harness connector

2.

Suction pipe installation bolt

3.

Wheel speed sensor harness

connector connection

4.

Wheel speed sensor harness clip

connection

>>A<<

5.

Brake tube connection

6.

Brake tube and clip connection

7.

Suction pipe, liquid pipe and clip

connection

8.

Hydraulic unit (ASC-ECU) and

hydraulic unit bracket

<<A>>

9.

Hydraulic unit (ASC-ECU)

10. Hydraulic unit bracket insulator

11. Hydraulic unit bracket B

12. Hydraulic unit bracket A

Removal steps (Continued)