Content .. 1738 1739 1740 1741 ..

Mitsubishi Outlander GS45X. Manual - part 1740

ON-VEHICLE SERVICE

TSB Revision

AUTOMATIC TRANSAXLE

23C-265

TRANSMISSION FLUID CHANGE

M1231021500187

If you have a transmission fluid changer, use this changer to

replace the transmission fluid. If you do not have a transmis-

sion fluid changer, replace the transmission fluid by the follow-

ing procedure.

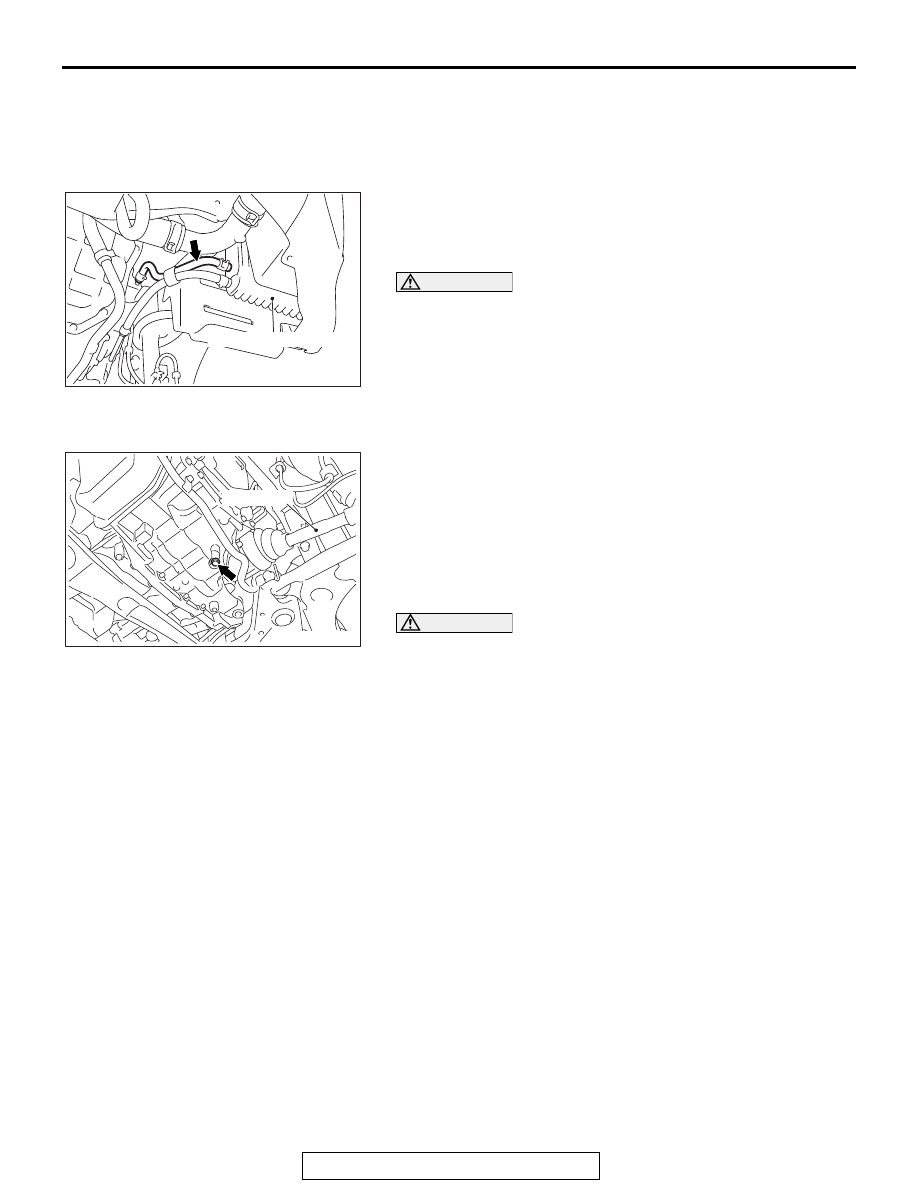

1. Disconnect the hose shown in the illustration which

connects the transaxle and the oil cooler (inside the

radiator). Place a container under the hose to collect the

discharge.

CAUTION

The engine should be stopped within one minute after it is

started. If all the transmission fluid has drained out before

then, the engine should be stopped at that point.

2. Start the engine and let the transmission fluid drain out.

(Running conditions: "N" range with engine idling)

Approximately 3.5 dm

3

(3.7 quarts) of transmission

fluid should be removed.

3. Remove the drain plug from the bottom of the transaxle case

to drain the transmission fluid.

Approximately 2.0 dm

3

(2.1 quarts) of transmission

fluid should be removed.

4. Install the drain plug with a new gasket, and tighten it to the

specified torque.

Tightening torque: 7.4

± 2.4 N⋅m (65 ± 21 in-lb)

CAUTION

Stop pouring if the full volume of transmission fluid cannot

be added.

5. Add new transmission fluid (DIA QUEEN ATF- J3) through

the oil filter tube.

Approximately 5.5 dm

3

(5.8 quarts) of transmission

fluid should be added.

6. Repeat the procedure in Step 2. (to pump out the rest of the

contaminated transmission fluid)

7. Add new transmission fluid (DIA QUEEN ATF- J3) through

the oil filter tube.

Approximately 3.5 dm

3

(3.7 quarts) of transmission

fluid should be added.

NOTE: Check for contamination or a burnt odor. If the trans-

mission fluid is still contaminated or burnt, repeat Steps 6

and 7 before proceeding to Step 8.

AC607757AB

Transmission fluid cooler

AC607758 AB

Drive shaft