Content .. 1564 1565 1566 1567 ..

Mitsubishi Outlander GS45X. Manual - part 1566

ON-VEHICLE SERVICE

TSB Revision

POWER STEERING

37-27

4. Connect the all of the injector connectors.

5. Start the engine (idling).

6. Turn the steering wheel to the left and right until there are no

air bubbles in the oil reservoir.

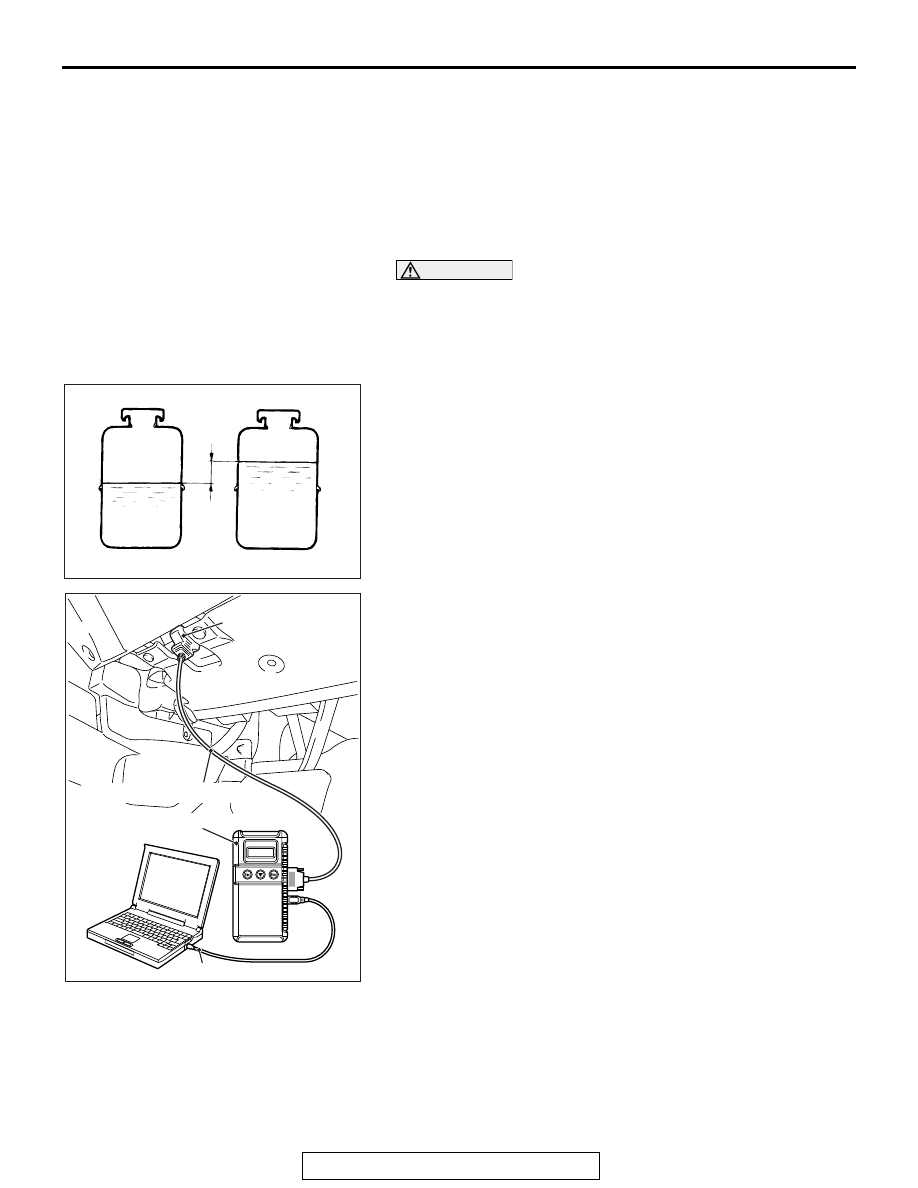

7. Confirm that the fluid is not milky, and that the level is

between the high and low dipstick marks.

8. Confirm that there is very little change in the fluid level when

the steering wheel is turned left and right.

CAUTION

If the fluid level rises suddenly after the engine is stopped,

the air has not been completely bled. If air bleeding is not

complete, there will be abnormal noises from the pump

and the flow-control valve, and this condition could cause

reduce the life of the power steering components.

9. Confirm that the change in the fluid level is no more than 5

mm (0.2 inch) when the engine is stopped and when it is

running.

10.If the change of the fluid level is 5 mm (0.2 inch) or more,

the air has not been completely bled from the system. The

air bleeding procedure must be repeated.

11.Use scan tool to check if the diagnostic trouble code is set. If

the diagnostic trouble code is set, erase it.

AC608306

With engine stopped

AC

Fluid level change: Within 5 mm (0.2 in)

With engine running

AC505420 AF

M.U.T.-III main harness A

V. C. I.

USB cable

Diagnosis connector