Content .. 1213 1214 1215 1216 ..

Mitsubishi Outlander GS45X. Manual - part 1215

GENERATOR AND DRIVE BELT

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-13

REMOVAL SERVICE POINT

.

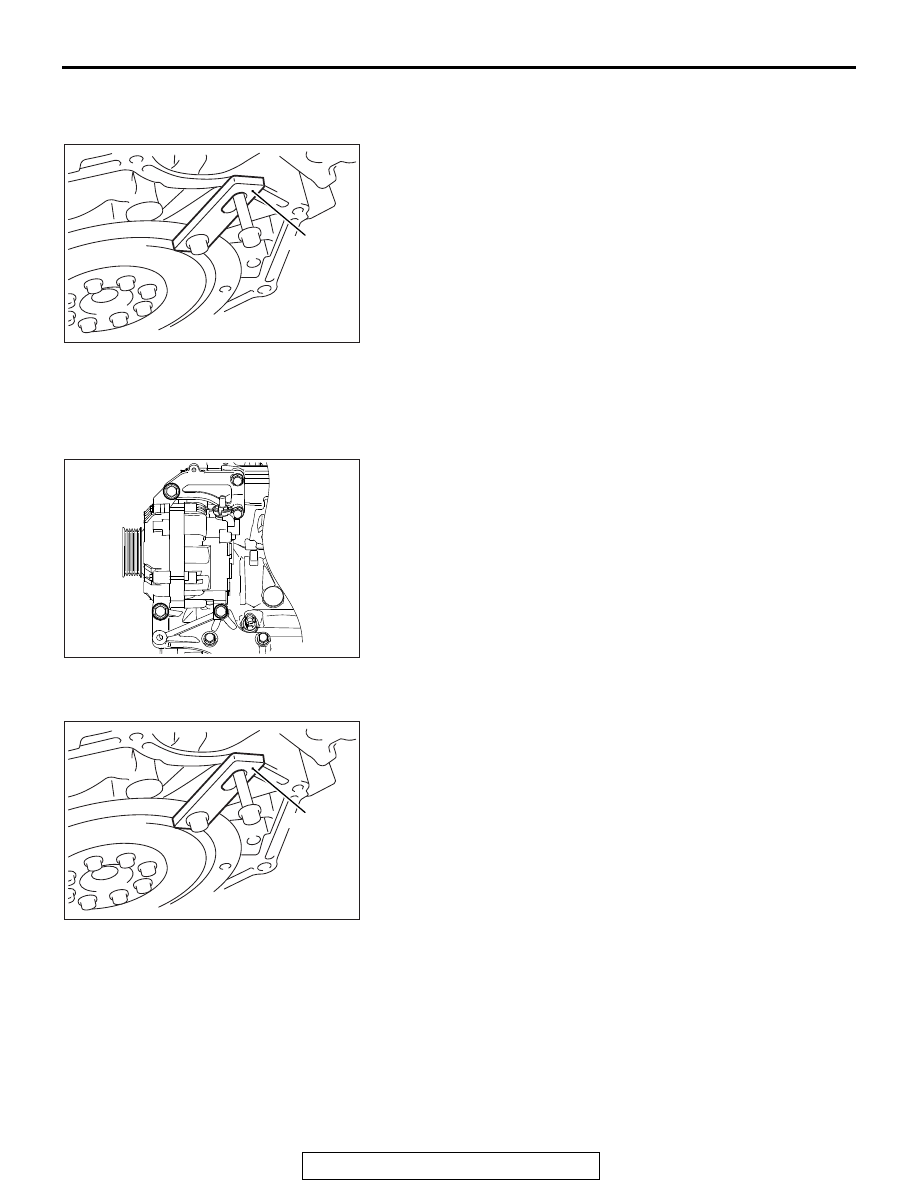

<<A>> CRANKSHAFT BOLT REMOVAL

1. Using special tool MD998781, hold the drive plate.

2. Remove the crankshaft bolt.

INSTALLATION SERVICE POINT

.

>>A<< GENERATOR INSTALLATION

1. Temporarily tighten the alternator to the alternator bracket.

2. In accordance with the tightening order shown in the

illustration, tighten the installation bolts for the alternator to

the specified torque.

Tightening torque: 47

± 11 N⋅m (35 ± 7 ft-lb)

.

>>B<< CRANKSHAFT BOLT INSTALLATION

1. Using special tool MD998781, hold the drive plate.

AK600940AC

MD998781

AK600845

1

2

3

AC

AK600940AC

MD998781