Content .. 1211 1212 1213 1214 ..

Mitsubishi Outlander GS45X. Manual - part 1213

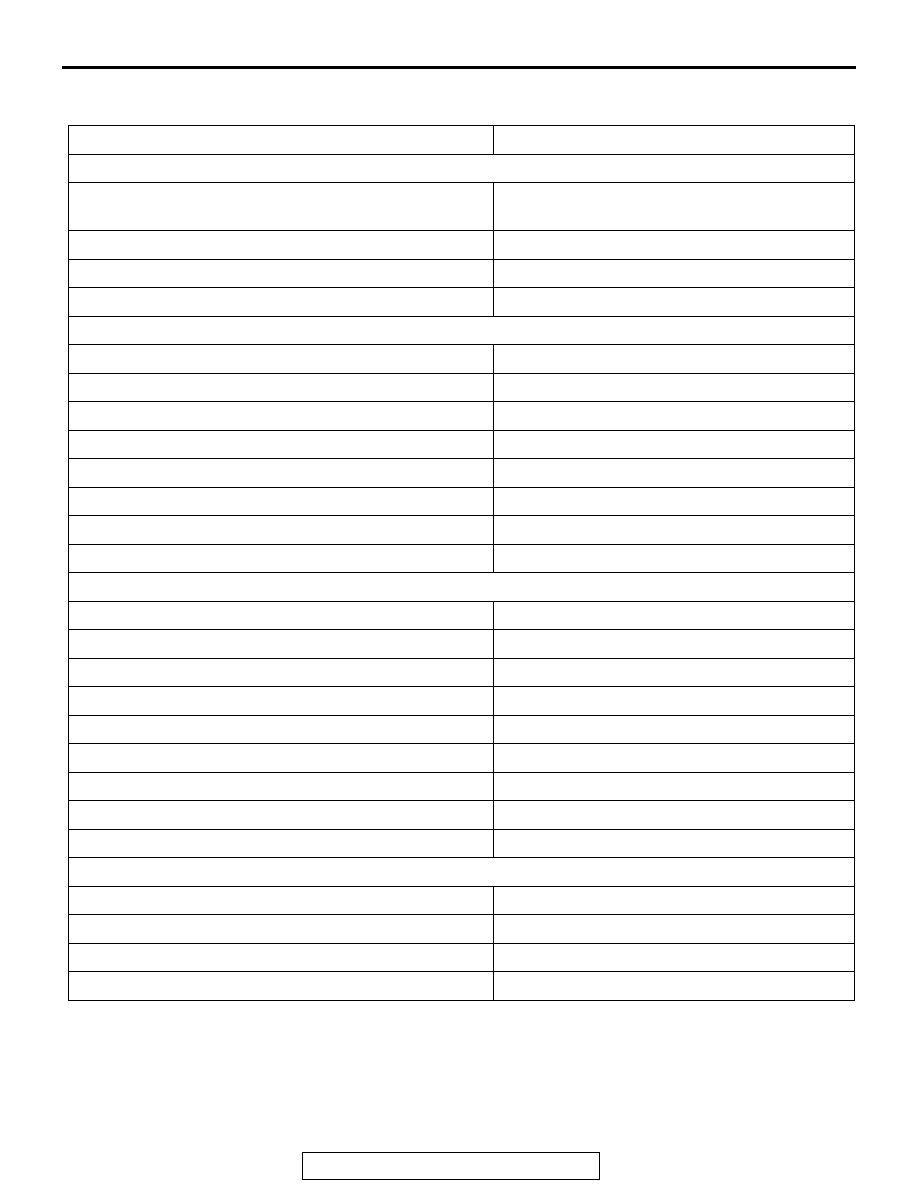

FASTENER TIGHTENING SPECIFICATIONS

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-5

FASTENER TIGHTENING SPECIFICATIONS

M1113023404260

Item

Specification

Generator and drive belt

Crankshaft bolt

200 N

⋅m (148 ft-lb) → 0 N⋅m (0 ft-lb) → 110 N⋅m

(81 ft-lb)

→ +60°

Drive belt auto tensioner bolt

23

± 6 N⋅m (17 ± 4 ft-lb)

Generator bracket bolt

23

± 6 N⋅m (17 ± 4 ft-lb)

Generator bolt

47

± 11 N⋅m (35 ± 7 ft-lb)

Intake manifold plenum and throttle body assembly

Exhaust gas recirculation pipe bolt

23

± 6 N⋅m (17 ± 4 ft-lb)

Throttle body bolt

23

± 6 N⋅m (17 ± 4 ft-lb)

Boost sensor bolt

5.0

± 1.0 N⋅m (45 ± 8 in-lb)

Solenoid valve bolt

5.0

± 1.0 N⋅m (45 ± 8 in-lb)

Throttle body stay bolt

23

± 6 N⋅m (17 ± 4 ft-lb)

Engine hanger right bolt

23

± 6 N⋅m (17 ± 4 ft-lb)

Intake manifold plenum stay bolt

23

± 6 N⋅m (17 ± 4 ft-lb)

Intake manifold plenum bolt

22

± 1 N⋅m (16 ± 1 ft-lb)

Timing belt

Timing belt front cover bolt

7.0

± 1.0 N⋅m (62 ± 8 in-lb)

Engine support bracket bolt M8

20

± 5 N⋅m (15 ± 3 ft-lb)

Engine support bracket bolt M10

48

± 11 N⋅m (36 ± 7 ft-lb)

Crankshaft position sensor bolt

9.5

± 2.5 N⋅m (84 ± 22 in-lb)

Auto-tensioner bolt

23

± 3 N⋅m (18 ± 2 ft-lb)

Tensioner arm bolt

41

± 10 N⋅m (30 ± 7 ft-lb)

Idler pulley bolt

41

± 10 N⋅m (30 ± 7 ft-lb)

Camshaft sprocket bolt

90

± 10 N⋅m (65 ± 7 ft-lb)

Timing belt rear cover bolt

10

± 2 N⋅m (89 ± 17 in-lb)

Intake manifold

Ignition coil bolt

9.5

± 2.5 N⋅m (84 ± 22 in-lb)

Spark plugs

18

± 2 N⋅m (13 ± 1 ft-lb)

Injector and fuel rail bolt

12

± 1 N⋅m (104 ± 9 in-lb)

Intake manifold nut

22

± 1 N⋅m (16 ± 1 ft-lb)