Mitsubishi Outlander (2013+). Manual - part 435

ON-VEHICLE SERVICE

BASIC BRAKE

35A-7

CAUTION

Replace the check valve when it is faulty.

ACC00529

Intake

manifold

side

Booster side

(1)

(2)

AB

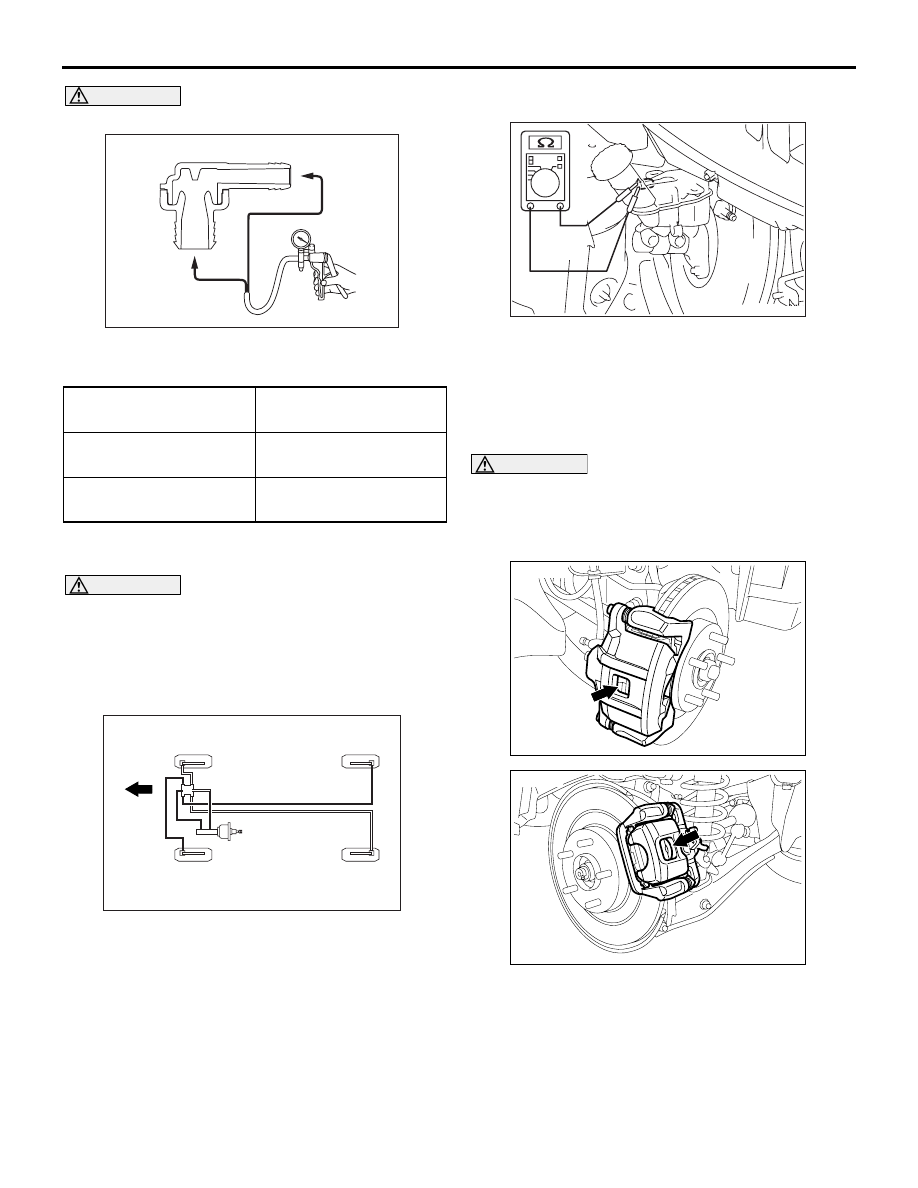

2. Using a vacuum pump, check operation of the

check valve.

Vacuum pump

connection

Normal condition

When connected to the

booster side (1)

Vacuum is generated

and maintained.

When connected to the

engine side (2)

No vacuum is generated.

BLEEDING

M1351001401362

CAUTION

Be sure to use the specified brand and type of

brake fluid. Avoid mixing with other type of brake

fluid.

Brake fluid: DOT3 or DOT4

BLEEDING OF BRAKE PIPELINE

AC607427AD

Front of

vehicle

3

4

1

2

1. Perform the bleeding in the order shown in the

figure.

BRAKE FLUID LEVEL SWITCH CHECK

M1351009100986

AC505508AB

The brake fluid level switch is normal when the fol-

lowing conditions are met: When the brake fluid level

is above "MIN," continuity is detected; and when the

level is below "MIN," no continuity is detected.

BRAKE PAD CHECK

M1351017300703

CAUTION

If there is a significant difference in thickness

between the brake pads at right and left, check

the sliding area and the run-out of the brake disc

(Refer to

ACB05917

<Front>

AB

ACB05918

<Rear>

AB

1. Visually check the thickness of brake pad from the

inspection hole of the caliper body.

Standard value: 10.0 mm <Front>, 9.0 mm

<Rear>

Limit: 2.0 mm <Front>, 1.5 mm <Rear>

2. If the brake pad thickness is less than the limit

value, replace the brake pad (Refer to