Mitsubishi Outlander (2013+). Manual - part 394

AC102513

MB990326

AB

FRONT AXLE HUB ASSEMBLY

FRONT AXLE

26-14

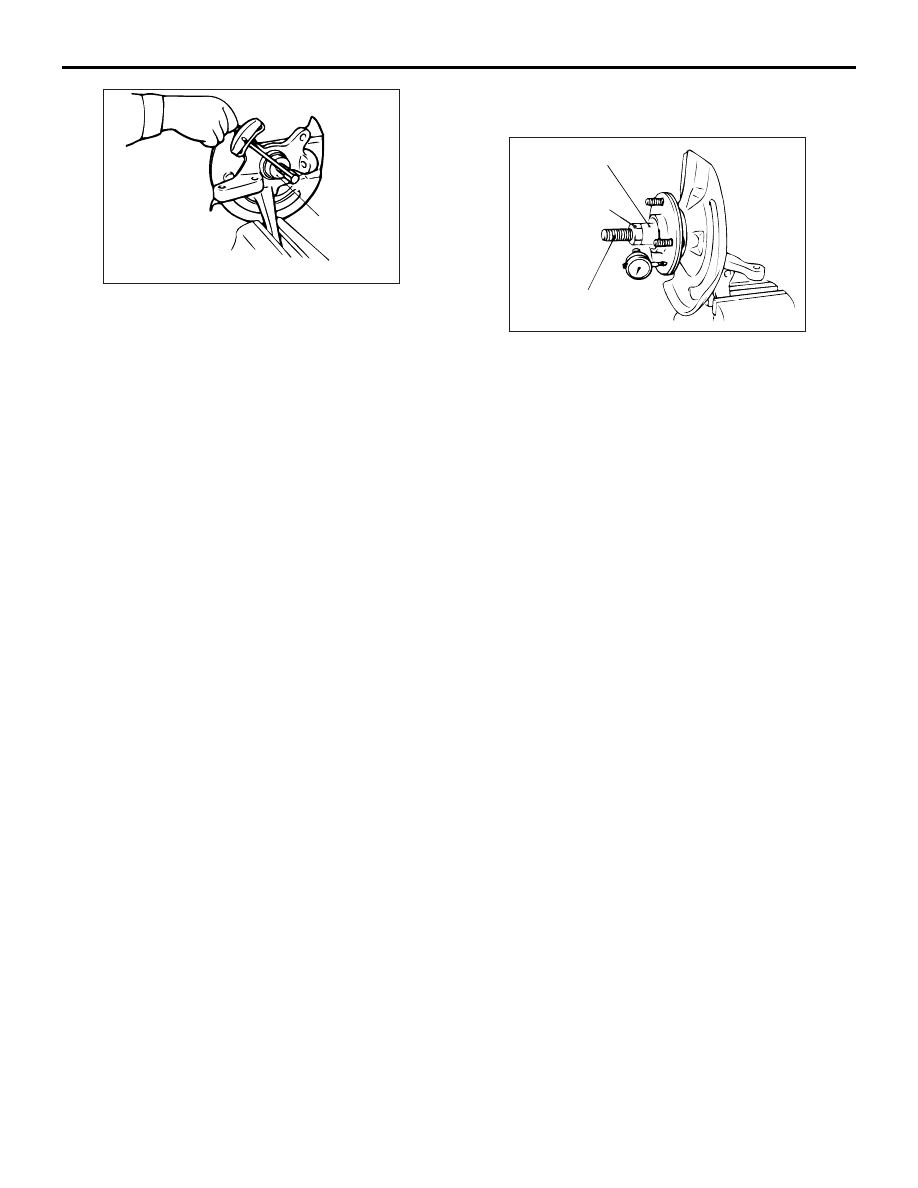

3. Use special tool preload socket (MB990326) to

measure the hub rotation starting torque.

Limit: 1.5 N

⋅m

4. Hub rotation starting torque should be within the

limit value, and there should be no roughness and

gritty feeling in rotation.

>>D<< WHEEL BEARING AXIAL PLAY

CHECK

AC102514 AN

MB991017

MB991000

270 ± 27 N·m

Tighten the nut with

the bolt secured.

1. Use the following special tools to measure the

wheel bearing axial play:

• Spacer (MB991000)

• Front hub remover and installer (MB991017)

Limit: 0.05 mm

2. If the axial play is not within the limit range while

the nut is tightened to the specified torque, the

bearing, hub and/or knuckle have probably not

been installed correctly. Replace the bearing and

re-install.

Tightening torque: 270

± 27 N⋅m