Mitsubishi Outlander (2013+). Manual - part 393

FRONT AXLE HUB ASSEMBLY

FRONT AXLE

26-10

INSTALLATION SERVICE POINTS

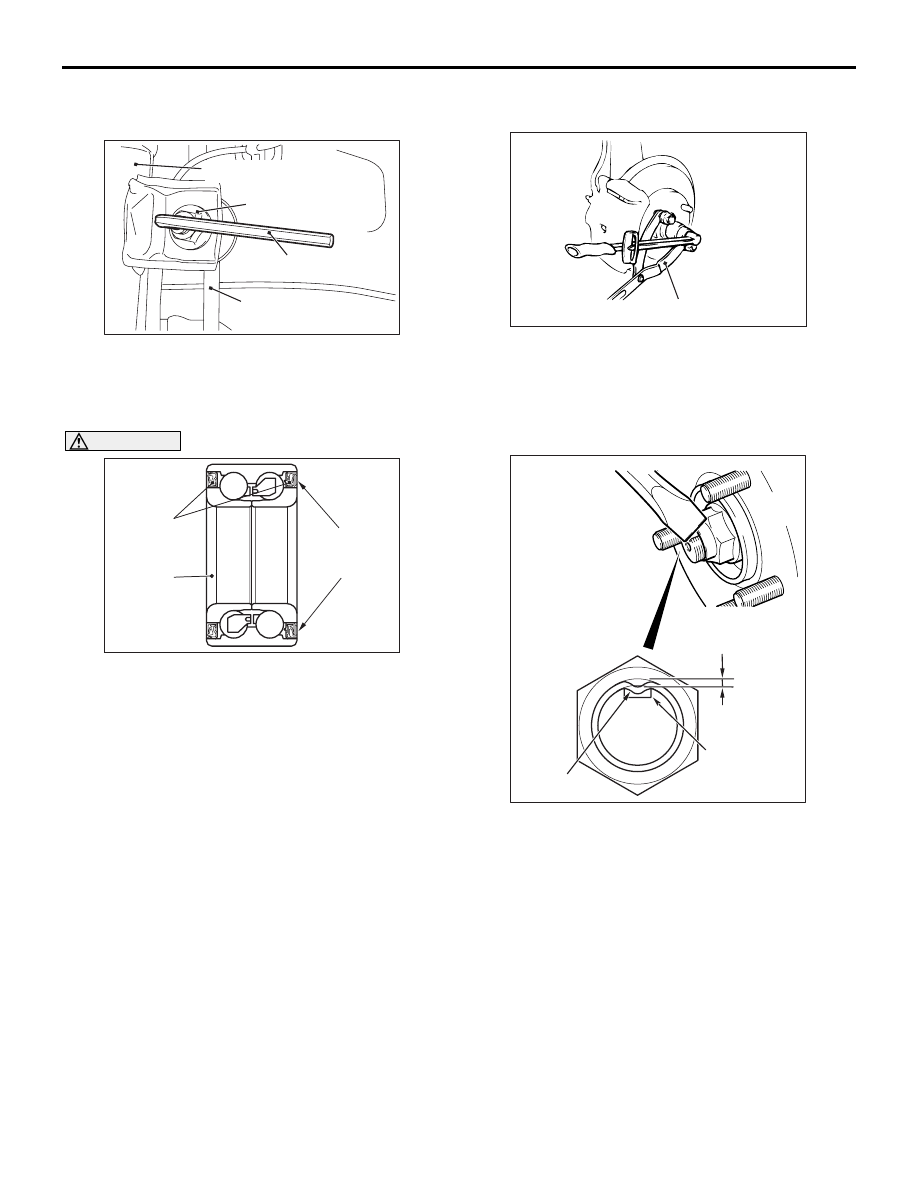

>>A<< STABILIZER LINK CONNECTION

AC613526 AB

Stabilizer link

Strut assembly

Hexagon wrench

Stabilizer link and

strut connection nut

Use a hexagon wrench to install the stabilizer link

and strut connection nut as shown in the figure.

>>B<< DRIVESHAFT NUT INSTALLATION

CAUTION

•

AC504925

Oil seal

Magnetic

encoder

AC

Wheel

bearing

The magnetic encoder collects metallic particles

easily, because it is magnetized. Make sure

that the magnetic encoder should not collect

metallic particles. Check that there is not any

trouble prior to reassembling it.

• When installing the driveshaft, make sure that

it does not contact with the magnetic encoder

(integrated with the inner oil seal) to avoid

damage.

• Do not apply the vehicle weight on the wheel

bearing before fully tightening the driveshaft

nut. Otherwise, the wheel bearing may be bro-

ken.

• Insert the driveshaft so that no hub bolt is ver-

tically above the groove of the driveshaft

assembly.

1. Check the hub seated surface for damage or

corrosion. Whenever solvent is used for removing

the corrosion, the surface should be degreased.

2. Check that the new driveshaft nut can be turned

smoothly by hand. Then tighten it until it is seated.

ACB04979AB

MB990767

3. Using special tool front hub and flange yoke

holder (MB990767), tighten the driveshaft nut.

Tightening torque: 270

± 27 N⋅m

4. After tightening to the specified torque, check that

the nut is seated securely.

ACA01211

1.6 mm

or more

AC

Groove

Staked portion

5. Use the chisel and a hammer to stake the nut until

the centre in the staked portion reaches the

shown dimension.

6. Finally, check that the nut is not cracked at its

staked portion.