Mitsubishi Outlander (2013+). Manual - part 356

EMISSION CONTROL <MPI>

ENGINE AND EMISSION CONTROL

17-25

EMISSION CONTROL <MPI>

GENERAL INFORMATION

M1173000102105

The emission control system consists of the following

subsystems:

• Crankcase emission control system

• Evaporative emission control system

•

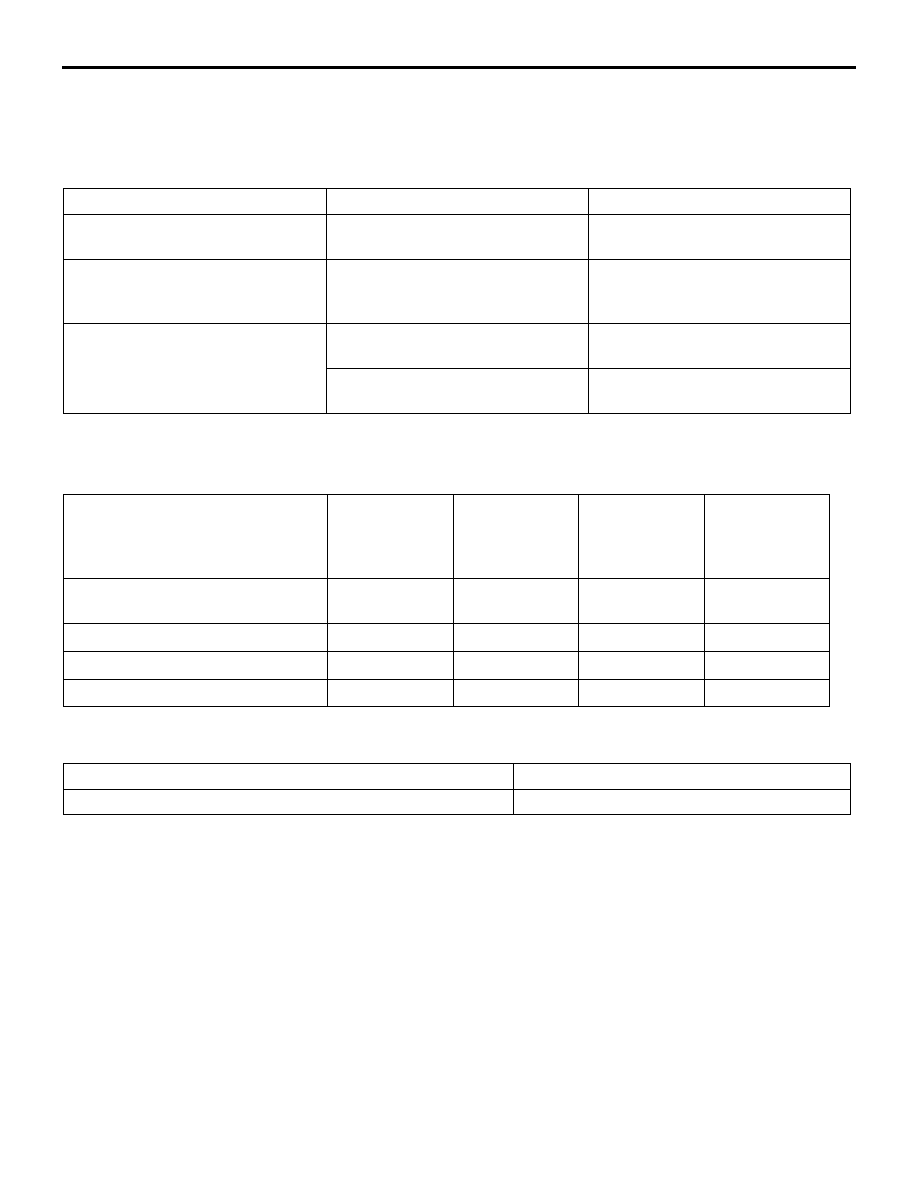

Items

Name

Specification

Crankcase emission control

system

Positive crankcase ventilation

valve

Variable flow type

(Purpose: HC reduction)

Evaporative emission control

system

• Canister

• Purge control solenoid valve

Equipped

Duty cycle type solenoid valve

(Purpose: HC reduction)

Emission reduction control system Air-fuel ratio control device - MPI

system

Oxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Catalytic converter

Monolith type

(Purpose: CO, HC, NOx reduction)

Emission reduction control system

EMISSION CONTROL DEVICE

REFERENCE TABLE

M1173006601224

Related parts

Crankcase

emission

control

system

Evaporative

emission

control

system

Air/fuel ratio

control

system

Catalytic

converter

Positive crankcase ventilation

valve

×

−

−

−

Purge control solenoid valve

−

×

−

−

MPI system component

−

×

×

−

Catalytic converter

−

−

−

×

SERVICE SPECIFICATION(S)

M1173000301593

Item

Standard value

Purge control solenoid valve coil resistance (at 20

°C) Ω

22

− 26