Mitsubishi Outlander (2013+). Manual - part 321

TROUBLESHOOTING

MULTIPOINT FUEL INJECTION (MPI)

13A-165

NOTE: *1: On the new vehicle (mileage: 500 km or less), air flow sensor output value may be higher by

approximately 10 %.

NOTE: *2: On the new vehicle (mileage: 500 km or less), injector drive time may be longer by approximately

10 %.

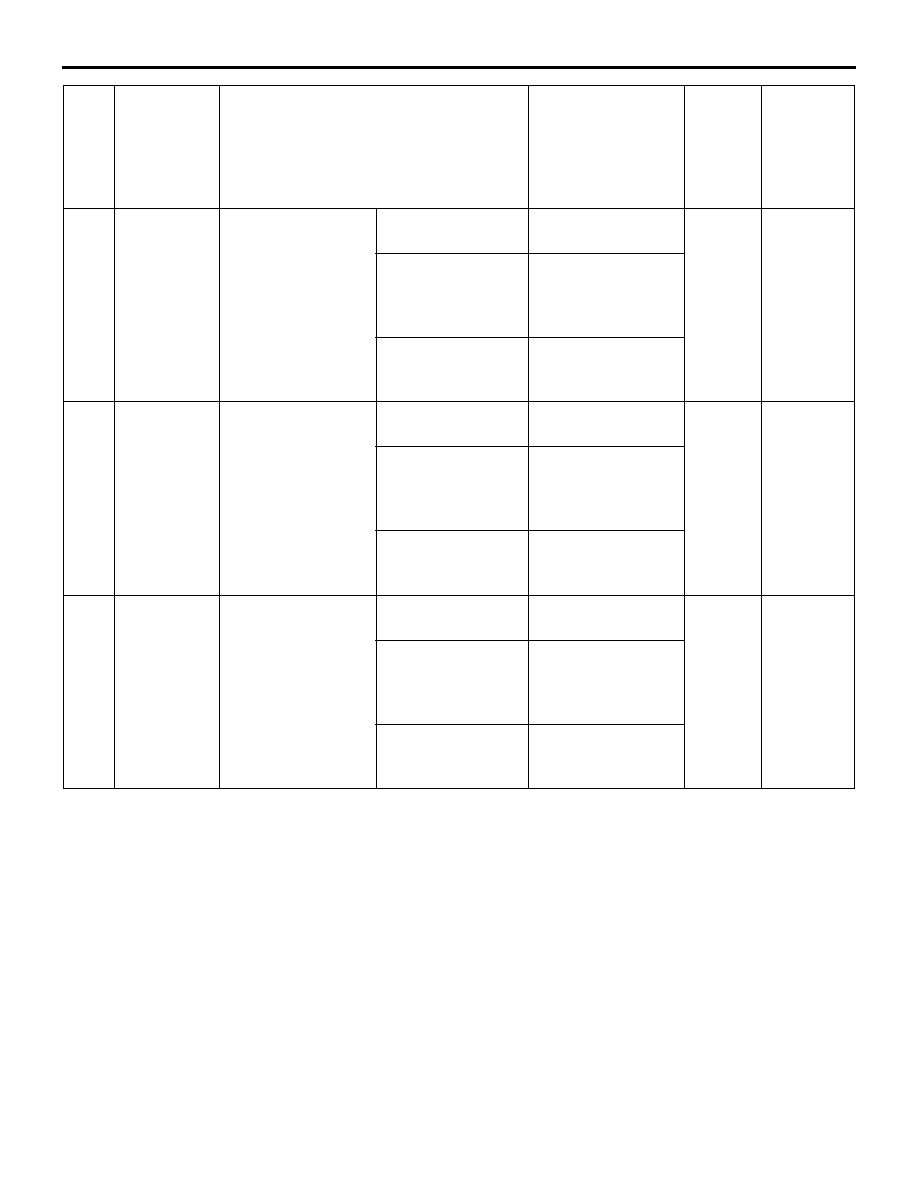

Engine-ECU monitoring items

• This monitor item includes many useful items for understanding the engine conditions controlled by the

engine-ECU.

• However, it is hard to show the definite specification of each item, since its value may vary to a large

extent with a little difference in the measuring conditions, environment, and changes with the lapse of

time, etc. on the objective vehicle. Therefore, this document will describe only the check conditions, dis-

play range, and behaviour of numeric values.

BE

Accelerator

pedal

position

sensor

(main)

Ignition switch:

"ON"

Release the

accelerator pedal

16

− 24 %

Code

No.

P2122,

P2123

Depress the

accelerator pedal

Increases in

response to the

pedal depression

stroke

Depress the

accelerator pedal

fully

80 % or more

BF

Accelerator

pedal

position

sensor (sub)

Ignition switch:

"ON"

Release the

accelerator pedal

6

− 14 %

Code

No.

P2127,

P2128

Depress the

accelerator pedal

Increases in

response to the

pedal depression

stroke

Depress the

accelerator pedal

fully

40 % or more

DD

Accelerator

pedal

position

sensor

(relative

value)

Ignition switch:

"ON"

Release the

accelerator pedal

0

− 5 %

−

−

Depress the

accelerator pedal

Increases in

response to the

pedal depression

stroke

Depress the

accelerator pedal

fully

95

− 100 %

Item

No.

Inspection

Item

Inspection condition

Normal condition

Code

No. or

inspecti

on

procedu

re No.

Reference

page