Mitsubishi Outlander (2013+). Manual - part 276

AK502749

90˚

Paint mark

AC

Paint mark

PISTON AND CONNECTING ROD

ENGINE OVERHAUL

11B-58

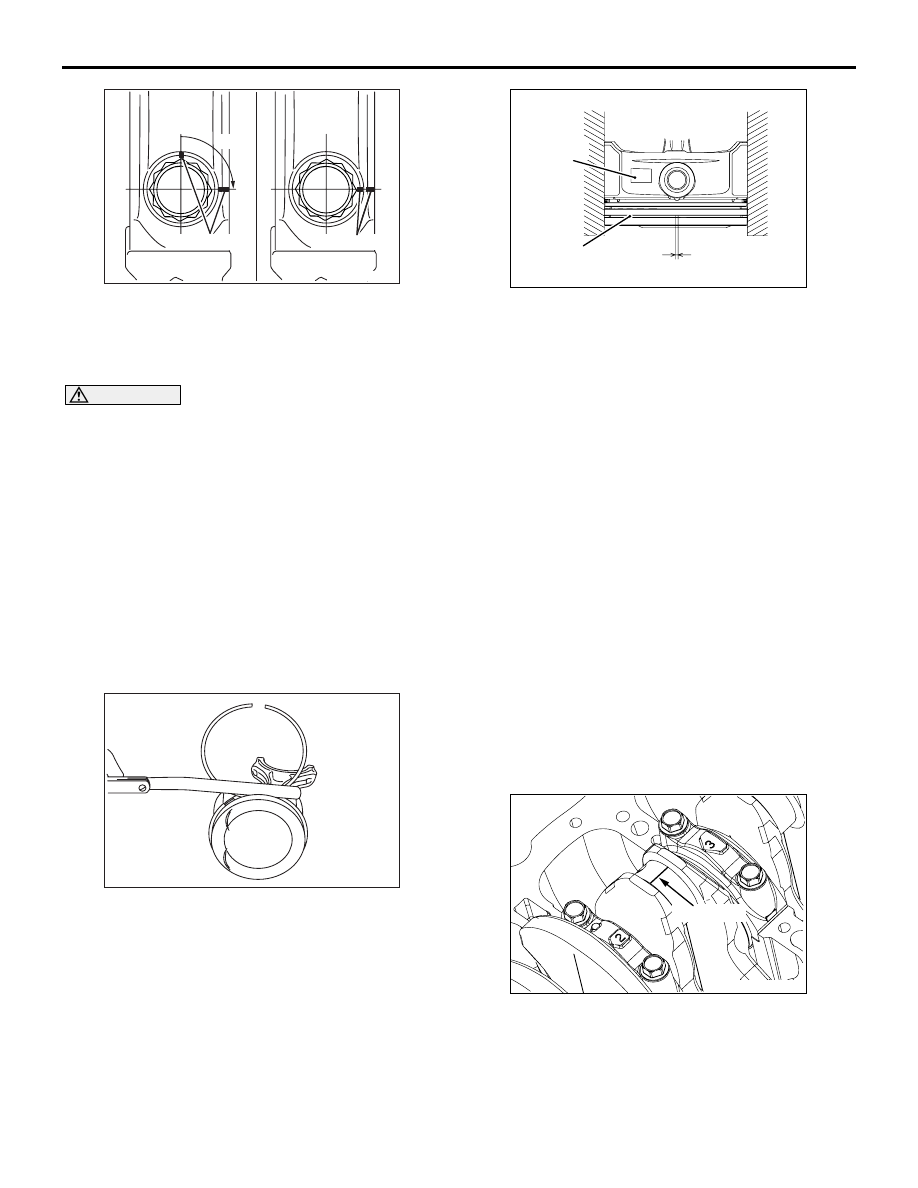

6. Put a paint mark on the bolt head as illustrated.

7. Put a paint mark on the connecting rod at 90

°

position in the tightening direction of the bolt with

reference to the paint mark position of the bolt.

CAUTION

• When the tightening angle is smaller than the

specified tightening angle, the appropriate

tightening capacity cannot be secured.

• When the tightening angle is larger than the

specified tightening angle, remove the bolt to

start from the beginning again according to

the procedure.

8. Tighten the bolt 90

°, and make sure that the paint

mark of the connecting rod is aligned with that of

the bolt.

INSPECTION

M1113008502703

PISTON RINGS

AK502751

1. Check clearance between piston rings and ring

grooves. If the limit is exceeded, replace piston

rings or piston, or both.

Standard value:

No. 1 ring: 0.03

− 0.07 mm

No. 2 ring: 0.03

− 0.07 mm

Limit: 0.1 mm

AK503370AG

Press down ring

with piston

End gap

Piston ring

Front mark

2. Put piston rings into the cylinder bore, press them

against the piston top face, and push them in.

After achieving squareness, measure the end gap

with a thickness gauge. If the end gap is

excessive, replace piston rings.

Standard value:

No. 1 ring: 0.15

− 0.28 mm <4B11>

No. 1 ring: 0.15

− 0.25 mm <4B12>

No. 2 ring: 0.30

− 0.45 mm <4B11>

No. 2 ring: 0.25

− 0.40 mm <4B12>

Oil ring: 0.10

− 0.35 mm

Limit:

No. 1 ring: 0.8 mm

No. 2 ring: 0.8 mm

Oil ring: 1.0 mm

CRANKSHAFT PIN OIL CLEARANCE

(PLASTIGAGE METHOD)

1. Wipe oil off the crankshaft pin and connecting rod

bearing.

2. Place a Plastigage in length equal to the bearing

width on the pin shaft straight in alignment with

the shaft centre.

AK503373AC

Plastigage

3. Carefully install the connecting rod cap and

tighten bolts to the specified torque of 5.0 N

⋅m →

20 N

⋅m → +90°.

4. Remove bolts and gently remove the connecting

rod cap.