Mitsubishi Outlander (2013+). Manual - part 277

CRANKSHAFT AND CYLINDER BLOCK

ENGINE OVERHAUL

11B-62

CAUTION

• When the tightening angle is smaller than the

specified tightening angle, the appropriate

tightening capacity cannot be secured.

• When the tightening angle is larger than the

specified tightening angle, remove the bolt to

start from the beginning again according to

the procedure.

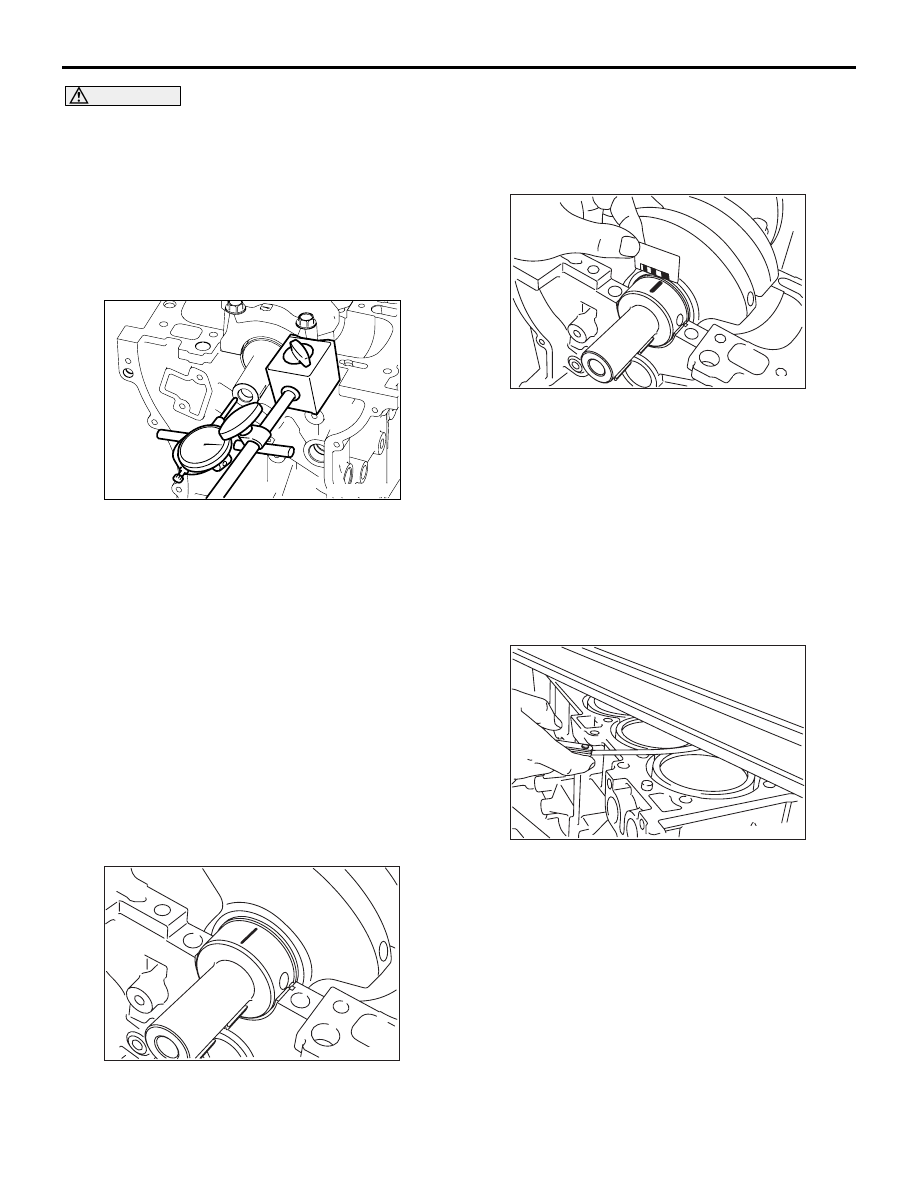

5. Use special tool Angle gauge (MB991614) to

tighten bolts 45

° according to the tightening order.

AK503375

6. Check axial play of the crankshaft after installing

the crankshaft bearing cap. If the axial play

exceeds the limit, replace the thrust bearing.

Standard value: 0.05

− 0.25 mm

Limit: 0.4 mm

INSPECTION

M1113008802823

CRANKSHAFT OIL CLEARANCE

(PLASTIGAGE METHOD)

Oil clearance can be easily measured by using a

"Plastigage."

When using a "Plastigage," perform measurement in

the following procedure.

1. Fully wipe oil off the outside diameter of the

crankshaft and inside diameter of the bearing.

2. Assemble the crankshaft.

AK502747

3. Place a Plastigage in length equal to the bearing

width on the journal shaft straight in alignment

with the shaft centre.

4. Carefully install the bearing cap and tighten the

bolt according to the main point of installation

>>B<<.

5. Remove the bolt, and then carefully remove the

crankshaft bearing cap.

AK502748

6. Measure the crushed Plastigage width (area most

widely crushed) using a scale printed on the

Plastigage bag.

Standard value: 0.012

− 0.030 mm

Limit: 0.1 mm

CYLINDER BLOCK

1. Visually check the cylinder block for scratch, rust

and corrosion. Use a flaw detecting agent to

check for cracks. If it is found faulty, repair or

replace it.

AK502746

2. Measure distortion on the top surface of the

cylinder block using a straight edge and thickness

gauge.

If distortion exceeds the limit, grind and repair it.

A gasket or the like must not be adhered to the

top surface of the cylinder block during

measurement.

Distortion on bottom

Standard value: Within 0.05 mm

Limit: 0.2 mm

Grinding limit: 0.2 mm

3. Check the cylinder wall for scratch or seizure. If

there is any defect, replace the cylinder block.