Mitsubishi Outlander (2013+). Manual - part 272

AK503333AC

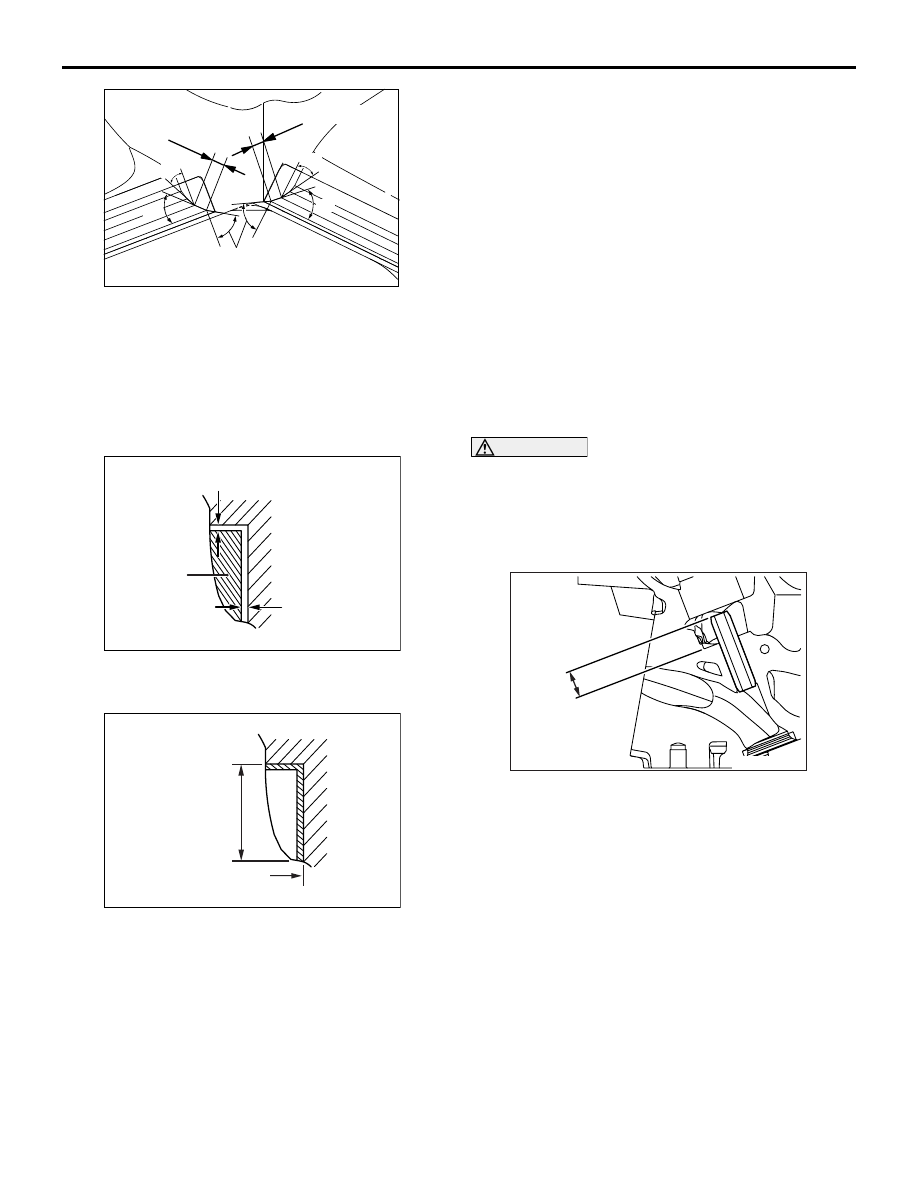

30˚

60˚

30˚

1.35 – 1.65 mm

1.16 – 1.46 mm

45˚

45˚

CYLINDER HEAD AND VALVES

ENGINE OVERHAUL

11B-42

2. Repair the valve seat so that seat width and seat

angle are to the specified shape.

3. Lap valve and valve seat with lapping compound

after repairing valve seat.

REPLACEMENT PROCEDURE OF VALVE

SEAT

AK300719AB

0.5 – 1 mm

0.5 – 1 mm

Cut

1. Scrape the valve seat to be replaced from inside

to make its wall thickness thin before pulling out.

AK300720AB

Oversize hole diameter

Valve seat

height

2. Repair the valve seat hole of the cylinder head to

match it with the diameter of the oversize valve

seat to be press fitted.

Inlet valve seat bore diameter:

0.3 O.S.: 36.22

− 36.24 mm

Exhaust valve seat bore diameter:

0.3 O.S.: 30.22

− 30.24 mm

3. Press fit the valve seat, taking care not to score

the cylinder head bore at room temperature.

4. Ream the valve seat.

Refer to "Repair procedure of valve seat."

REPLACEMENT PROCEDURE OF VALVE

GUIDE

1. Pull out the valve guide with a press toward the

cylinder block side.

2. Ream the valve guide hole of the cylinder head to

match it with the diameter of the oversize valve

guide to be press fitted.

CAUTION

Do not use a valve guide with the same size as

that of the pulled out valve guide because it can-

not be press fitted.

Valve guide bore diameter

0.25 O.S.: 11.23

− 11.25 mm

AK603511AC

14.6 – 15.2 mm

3. Press fit the valve guide to the illustrated

dimension.

Standard value: 14.6

− 15.2 mm

NOTE: Press fit the valve guide from the cylinder

head top surface.

4. After pressing fit the valve guide, insert a new

valve to check for sliding.