Mitsubishi Outlander (2013+). Manual - part 271

CYLINDER HEAD AND VALVES

ENGINE OVERHAUL

11B-38

REMOVAL SERVICE POINTS

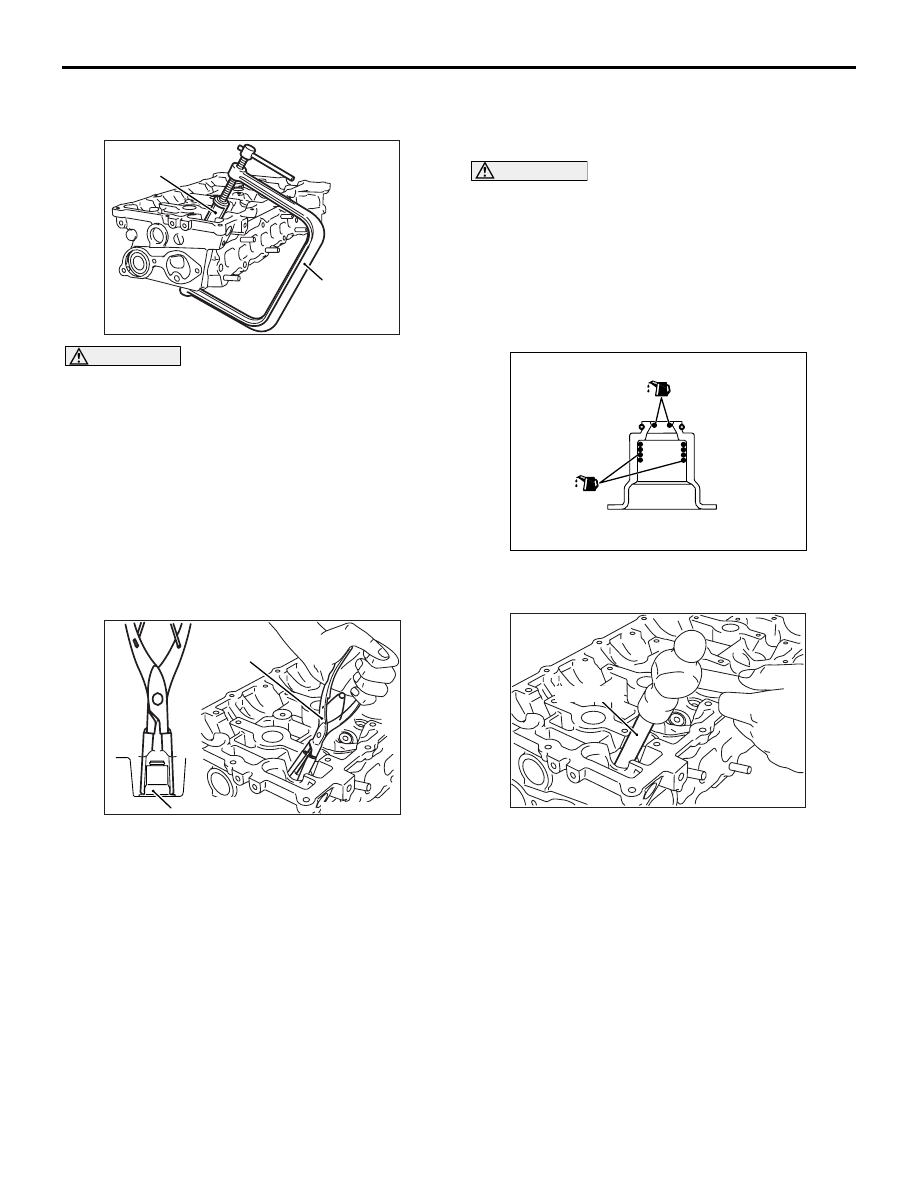

<<A>> RETAINER LOCK REMOVAL

AK502741AC

MB992089

MD998735

CAUTION

Be careful not to allow retainer holder C to inter-

fere with the wall of the tappet hole and to dam-

age it.

Use a special tool to compress the valve spring and

to remove the retainer lock.

• Valve spring compressor (MD998735)

• Retainer holder C (MB992089)

NOTE: Store removed parts such as valves and

springs with tags describing cylinder No. and

installed position attached for reassembly.

<<B>> VALVE STEM SEAL REMOVAL

AK502782AC

Valve stem seal

MB992085

Use special tool Valve stem seal pliers (MB992085)

to firmly pinch the base (larger external shape) of the

stem seal and twist it right and left for pulling out.

INSTALLATION SERVICE POINTS

>>A<< VALVE STEM SEAL INSTALLA-

TION

CAUTION

• The valve stem seal must not be reused.

• Do not damage the tappet wall during assem-

bly.

• Be sure to use a special tool to install the

valve stem seal. Poor installation causes oil

loss via valve guides.

•

AK503378 AD

If oil is not applied, the valve stem seal may

rise to the surface after it is press fitted.

1. Apply a thin coat of engine oil to a new valve stem

seal.

AK502742AC

MD998737

2. Use special tool Valve stem seal installer

(MD998737) to press fit the valve stem seal into

the valve guide with the valve stem used as a

guide.