Mitsubishi Outlander (2013+). Manual - part 253

VALVE STEM SEAL

ENGINE MECHANICAL

11A-35

>>E<< CAMSHAFT BEARING/CAMSHAFT

AND CAMSHAFT SPROCKET ASSEMBLY

(EXHAUST SIDE) INSTALLATION

CAUTION

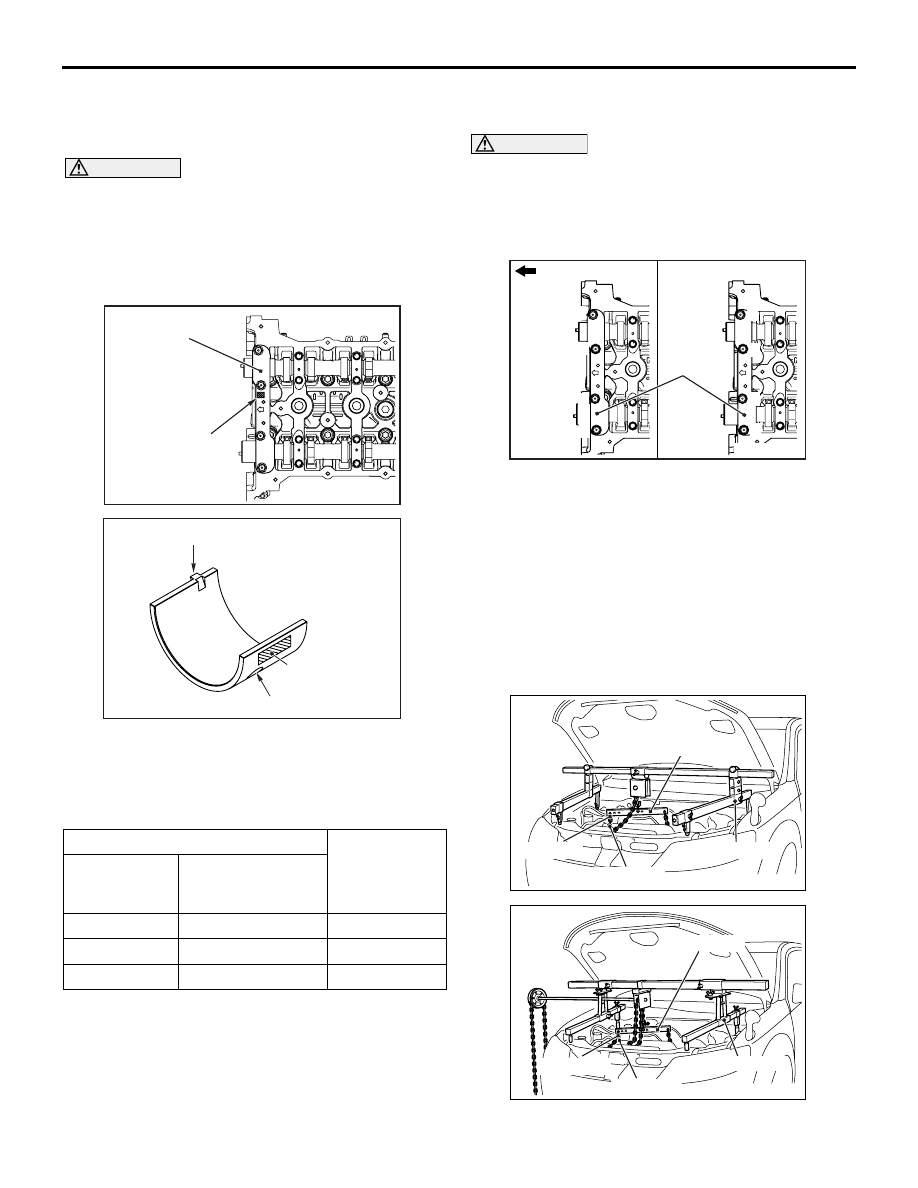

• Be careful not to drop the camshaft bearing.

•

AC611697

AC

Camshaft

bearing

front cap

assembly

Identification

mark

AC708893

Notch

Identification mark

Oil hole

AE

When installing the camshaft and camshaft

sprocket assembly (exhaust side), be careful

not to let the camshaft bearing which is

installed to the front cam bearing deviate from

its position.

When replacing the camshaft bearing, select a cam-

shaft bearing in relevant size according to the cam-

shaft bearing front cap identification mark in the table

below. Identification mark of the camshaft bearing is

painted in the position shown in the figure.

Camshaft

Camshaft

bearing

identification

mark

Identification

mark

Journal diameter

mm

1

40.000

− 40.008

1

2

40.008

− 40.016

2

3

40.016

− 40.024

3

>>F<< CAMSHAFT BEARING FRONT CAP

ASSEMBLY INSTALLATION

CAUTION

When the mounting bolts are tightened with the

camshaft bearing front cap tilted, the camshaft

bearing front cap is damaged. Install the cam-

shaft bearing front cap properly to the cylinder

head and camshaft.

AC511062

AB

4

3

2

1

4

3

2

1

(1)

(2)

Engine front

Camshaft

bearing

front cap

assembly

1. Install the camshaft bearing front cap to the

cylinder head, and temporarily tighten the

camshaft bearing front cap mounting bolts to the

specified torque in the order shown in the figure

(1).

Tightening torque: 17

± 3 N⋅m

2. Tighten again the camshaft bearing front cap

mounting bolts to the specified torque again in the

order shown in the figure (2).

Tightening torque: 30

± 2 N⋅m

AC506487

AD

MB991527

MB991454

MB991928

MB991956

AC506484

MB991527

AD

MB991454

MB991956

MB991895