Mitsubishi Outlander. Body repair manual - part 8

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-21

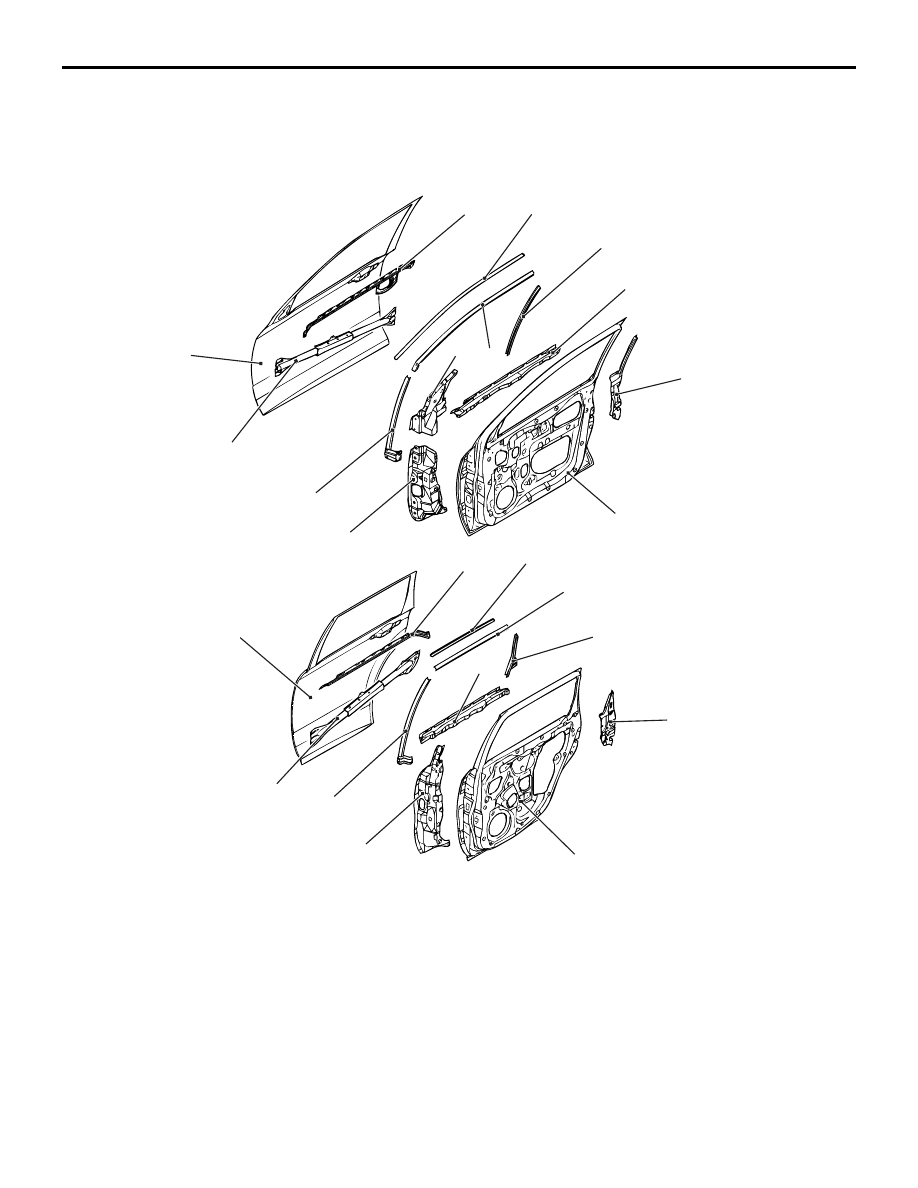

DOOR

M4010015000161

A one-piece top-bottom pressed door structure was

employed for the door outer panel and door inner

panel to improve door panel rigidity.

AB200222

AB200221

AB202356

Front Door

Rear Door

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

BT

23

1.

Front door hinge reinforcement

2.

Front door sash front

3.

Front door side door beam

4.

Front door outer panel

5.

Front door belt line reinforcement

6.

Front door weather strip hold upper

7.

Front door hinge reinforcement upper

8.

Front door sash upper

9.

Front door sash rear

10. Front door belt line reinforcement inner

11. Front door latch reinforcement

12. Front door inner panel

13. Rear door hinge reinforcement

14. Rear door sash front

15. Rear door side door beam

16. Rear door outer panel

17. Rear door belt line reinforcement

18. Rear door weather strip holder

19. Rear door sash upper

20. Rear door belt line reinforcement inner

21 Rear door sash rear

22. Rear door latch reinforcement

23. Rear door inner panel