Mitsubishi Outlander (2003+). Manual - part 415

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL

54A-55

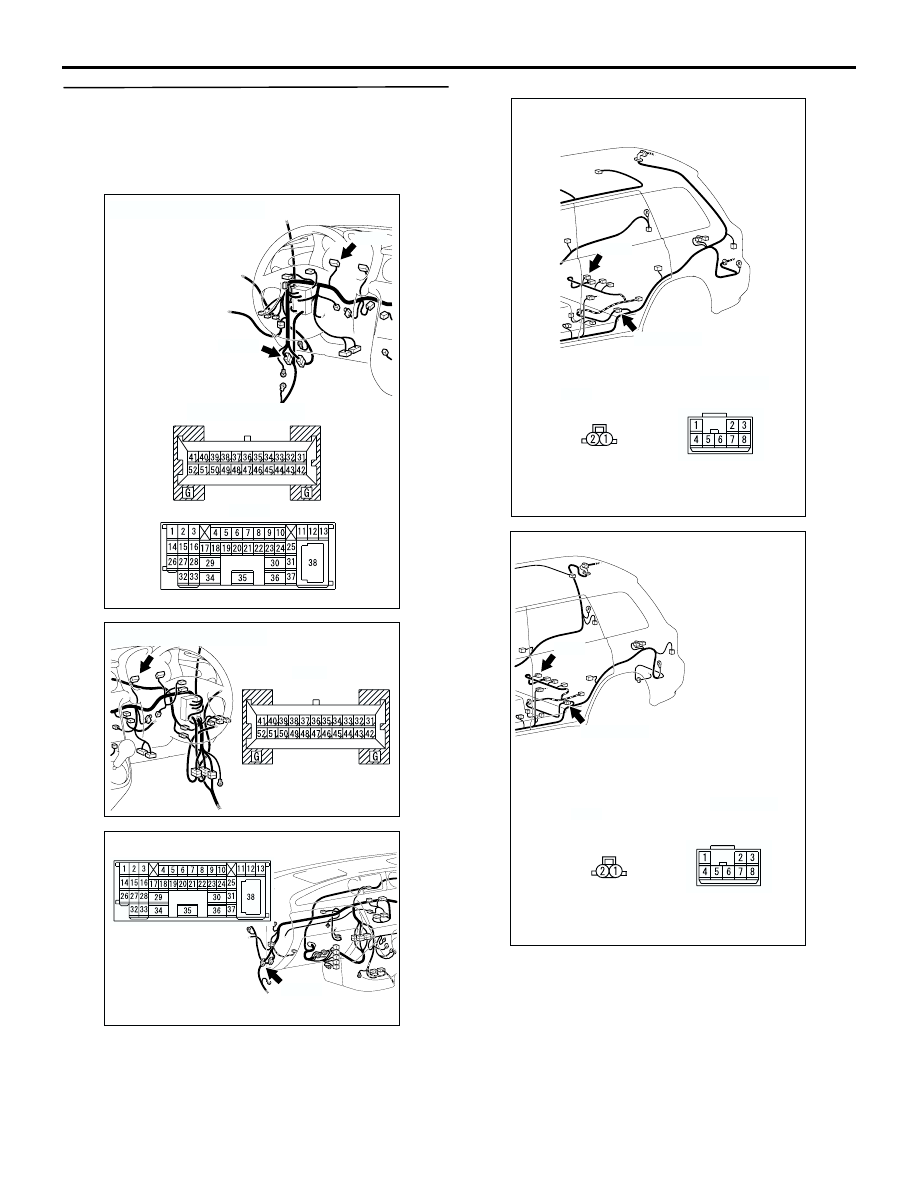

STEP 3. Check the wiring harness between

combination meter connector C-04 (terminal 43)

and fuel gauge unit connector D-15 (terminal 1)

<2WD> or fuel pump and gauge unit (main)

connector D-16 (terminal 2) <4WD>.

NOTE:

Prior to the wiring harness inspection, check fuel

gauge unit (sub) connector D-12, intermediate

connector C-117, D-24, and repair if necessary.

AC308717

AR

C-04

C-117

Connectors: C-04, C-117 <LHD>

C-04 harness side

C-117

AC308769

Connector: C-04 <RHD>

C-04 harness side

AS

AC308735

AU

C-117

Connector: C-117 <RHD>

AC301594

Connectors: D-12, D-24 <LHD>

AD

D-12

D-24

D-12

harness side

D-24

AC308788

Connectors: D-12, D-24 <RHD>

AE

D-12

D-24

D-12

harness side

D-24