Mitsubishi Outlander (2003+). Manual - part 258

SERVICE SPECIFICATIONS

BASIC BRAKE SYSTEM

35A-3

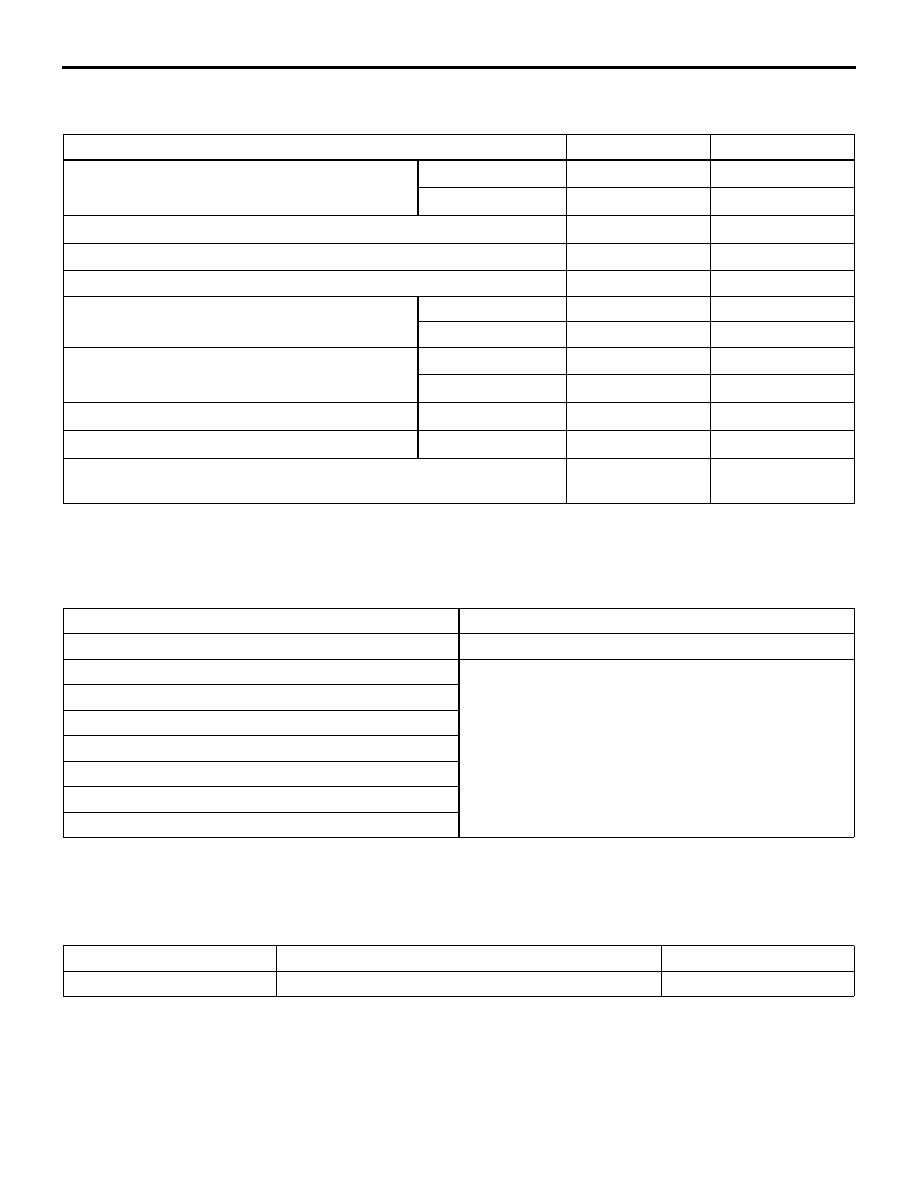

SERVICE SPECIFICATIONS

M1351000300530

LUBRICANTS

M1351000400377

SEALANT

M1351000500385

Item

Standard value

Limit

Brake pedal height mm

L.H. drive vehicles 150

−

153

−

R.H. drive vehicles 176.2

−

179.2

−

Brake pedal free play mm

3

−

8

−

Brake pedal to floor board clearance mm

100 or more

−

Disc brake pad thickness mm

10.0

2.0

Disc brake disc thickness mm

Front

24.0

22.4

Rear

10.0

8.4

Disc brake disc run-out mm

Front

−

0.04

Rear

−

0.05

Disc brake drag force N

Front/Rear

68 or less

−

Wheel bearing axial play mm

Front/Rear

−

0.05

Brake booster push rod protruding length mm (When applying

negative pressure of 66.7 kPa to the brake booster)

10.15

−

10.40

−

Item

Specified lubricant

Brake fluid

DOT3 or DOT4

Guide pin

Repair kit grease

Lock pin

Guide pin boot inner surface

Lock pin boot inner surface

Piston boot mounting grooves

Brake piston boot inner surface

Guide pin bush inner surface

Item

Specified sealant

Remark

Fitting thread part

3M ATD Part No.8661 or equivalent

Semi-drying sealant