Mitsubishi Outlander (2003+). Manual - part 259

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM

35A-7

BLEEDING

M1351001400400

CAUTION

Use only brake fluid DOT 3 or DOT 4. Never mix

the specified brake fluid with other fluid as it will

influence the braking performance significantly.

MASTER CYLINDER BLEEDING

The master cylinder used has no check valve, so if

bleeding is carried out by the following procedure,

bleeding of air from the brake pipeline will become

easier (When brake fluid is not contained in the

master cylinder).

1. Fill the reserve tank with brake fluid.

2. Keep the brake pedal depressed.

3. Have another person cover the master cylinder

outlet with a finger.

4. With the outlet still closed, release the brake

pedal.

5. Repeat steps 2

−

4 three or four times to fill the

inside of the master cylinder with brake fluid.

BRAKE LINE BLEEDING

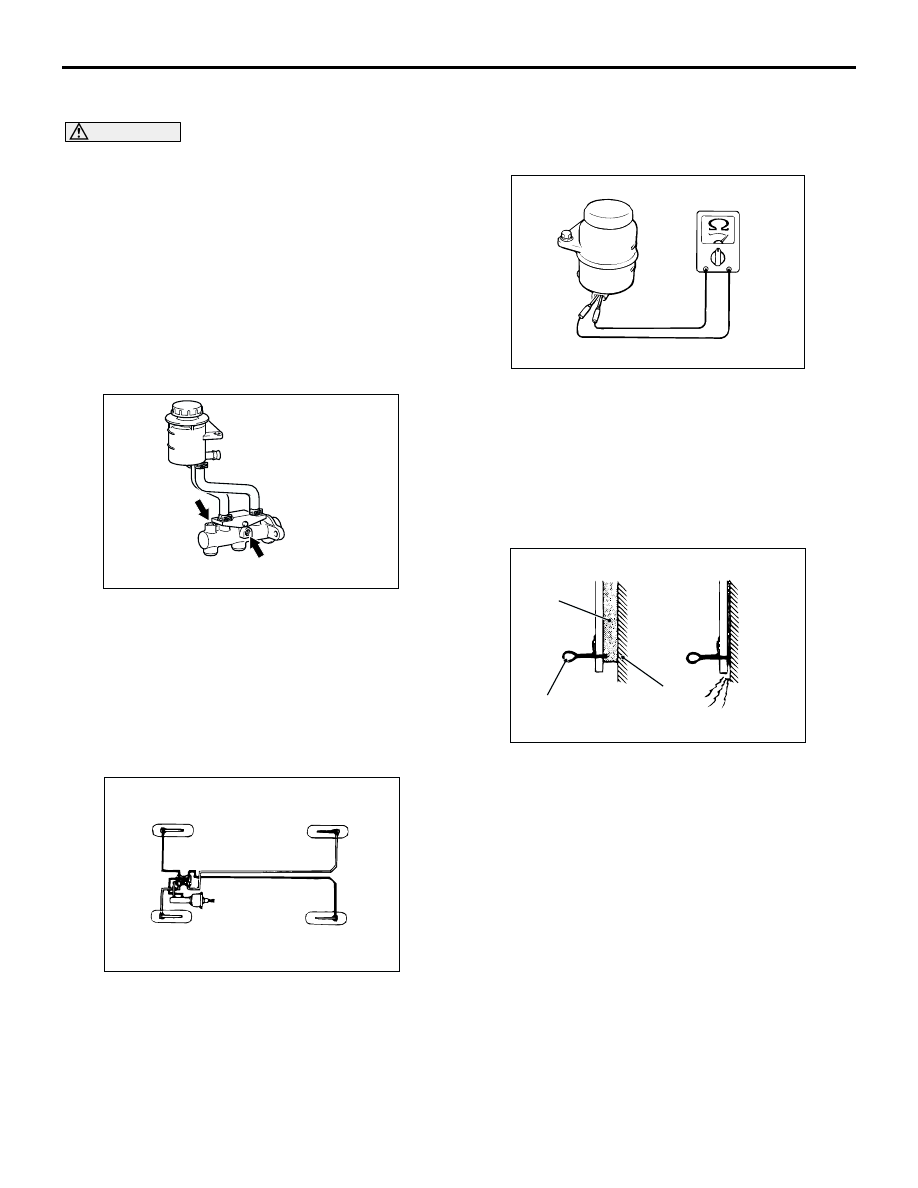

Start the engine and bleed the air in the sequence

shown in the figure.

BRAKE FLUID LEVEL SENSOR CHECK

M1351009100351

The brake fluid level sensor is in good condition if

there is no continuity when the float surface is above

"MIN" and if there is continuity when the float surface

is below "MIN".

DISC BRAKE PAD CHECK AND

REPLACEMENT

M1351002300343

NOTE:

The brake pads have indicators that contact the

brake disc when the brake pad thickness becomes 2

mm, and emit a squealing sound to warn the driver.

AC301227AB

Outlet

Outlet

AC301228AB

4

2

1

3

AC102357

AC000879

When new

When worn

AD

Pad

Wear indicator

Brake

disc