Mitsubishi Outlander (2003+). Manual - part 256

SHOCK ABSORBER ASSEMBLY

REAR SUSPENSION

34-21

WARNING

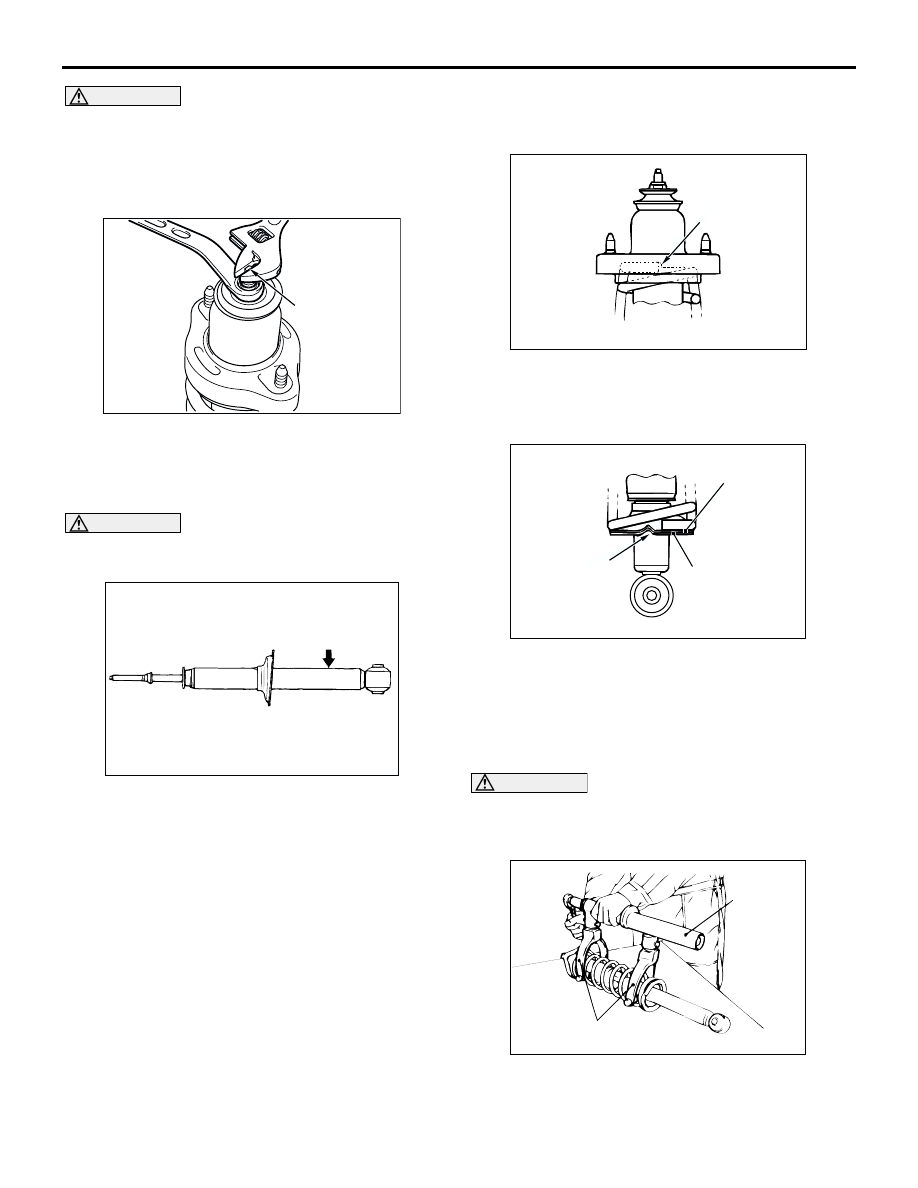

Do not use an impact wrench to remove the

self-locking nut. Vibration of the impact

wrench will cause special tools (MB991237

and MB991239) to slip and cause personal

injury.

2. While holding the piston rod, remove the

self-locking nut.

<<B>> SHOCK ABSORBER DISPOSAL

WARNING

Wear goggles when drilling to protect your

eyes from flying metal debris.

The gas must be discharged from the shock

absorber before discarding it. Place the shock

absorber horizontally with its piston rod extended.

Then drill a hole of approximately 3 mm in diameter

at the location shown in the illustration and discharge

the gas.

REASSEMBLY SERVICE POINTS

>>A<< UPPER SPRING PAD/LOWER SPRING

PAD INSTALLATION

<UPPER SPRING PAD>

Align the stepped section of the spring upper pad

with the upper end of the coil spring, and install the

spring upper pad.

<LOWER SPRING PAD>

Align the stepped section of the spring lower pad

with the stepped section of the spring seat of the

shock absorber, and install the spring lower pad.

>>B<< COIL SPRING INSTALLATION

CAUTION

Do not use an impact wrench to tighten the bolt

of special tool spring compressor body

(MB991237). It will break the special tool.

1. Use following special tools to compress the coil

spring, and install it to the lower spring pad.

•

MB991237: Spring Compressor Body

AC102268AC

Piston rod

AC102270 AC

AC304801AC

Spring upper pad

stepped section

AC304800 AB

Spring lower pad

Stepped section

Spring seat

AC001070

MB991237

MB991239

AB