Mitsubishi Outlander (2003+). Manual - part 146

ENGINE CONTROL

ENGINE AND EMISSION CONTROL

17-3

ENGINE CONTROL

GENERAL INFORMATION

M1171000100329

A cable-type accelerator mechanical

suspended-type pedal has been adopted.

SERVICE SPECIFICATIONS

M1171000300099

TROUBLESHOOTING

INTRODUCTION TO ENGINE CONTROL

SYSTEM DIAGNOSIS

M1171002000287

If there is a malfunction in the engine control system,

the accelerator cable, accelerator pedal or throttle

lever may be faulty.

ENGINE CONTROL SYSTEM

DIAGNOSTIC TROUBLESHOOTING

STRATEGY

M1171002100314

Use these steps to plan your diagnostic strategy.

If you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find an

engine control system fault.

1. Gather information from the customer.

2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify that the malfunction is eliminated.

SYMPTOM CHART

M1171002200322

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Throttle Valve will not Fully Open or Close <4G63>

DIAGNOSIS

STEP 1. Check the accelerator cable adjustment.

Q: Is the accelerator cable properly adjusted?

YES :

Go to Step 2 .

NO :

Adjust the accelerator cable (Refer to

). Then go to Step 3 .

STEP 2. Check the throttle valve.

Check that the throttle lever of the throttle body

assembly moves smoothly by moving it by hand.

Q: Does the throttle lever of the throttle body

assembly move smoothly?

YES :

Go to Step 3 .

NO :

Cleaning the throttle body (Refer to GROUP

13A, On-vehicle Service

), or

replace the throttle body assembly (Refer to

GROUP 13A, Throttle Body

Then go to Step 3 .

STEP 3. Retest the system.

Q: Does the throttle valve fully open and close?

YES :

The procedure is complete.

NO :

Return to Step 1 .

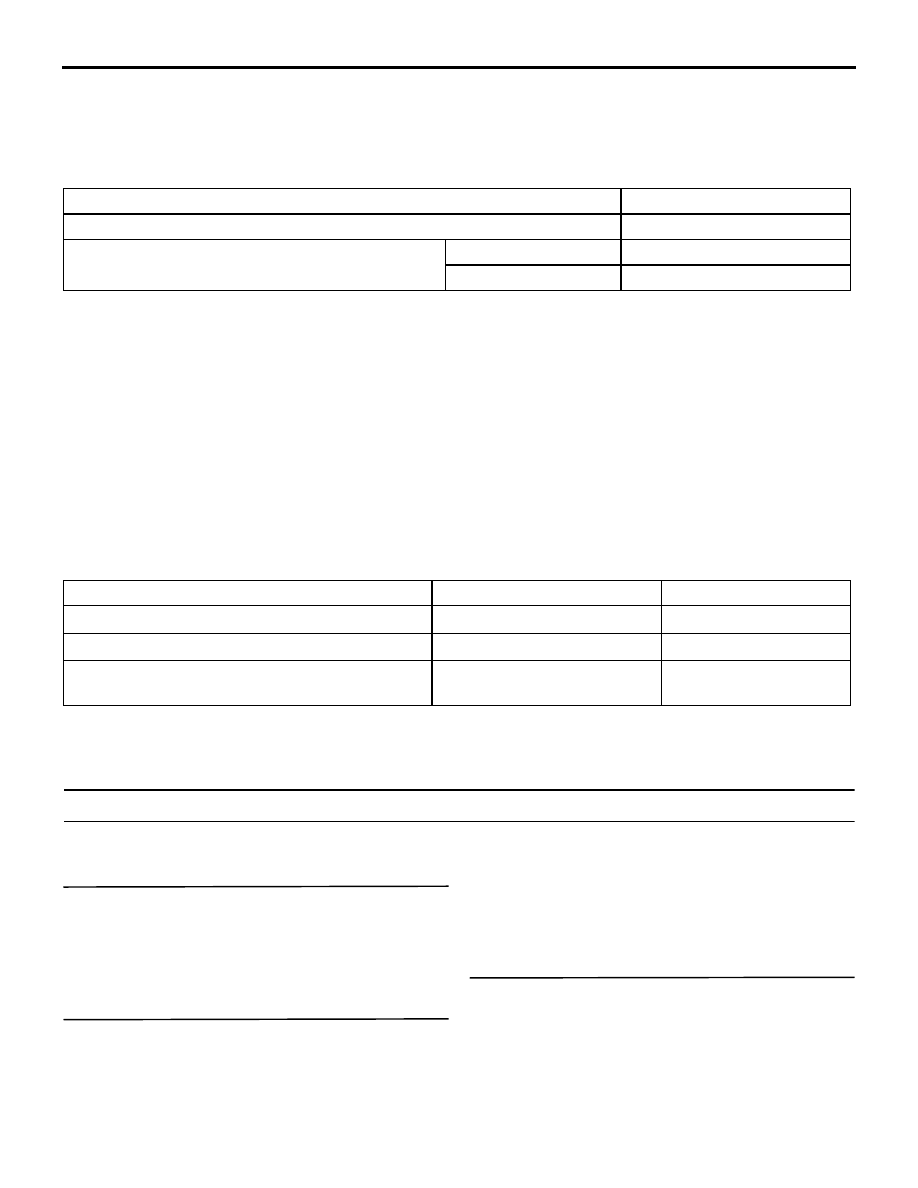

Items

Standard value

Accelerator cable play mm

1.0

−

2.0

Engine idle speed r/min

4G63

750

±

50

4G69

700

±

100

SYMPTOM

INSPECTION PROCEDURE

REFERENCE PAGE

Throttle valve will not fully open or close <4G63> 1

Throttle valve will not fully open or close <4G69> 2

Accelerator pedal operation is not smooth (over

acceleration)

3