Mitsubishi Outlander (2003+). Manual - part 10

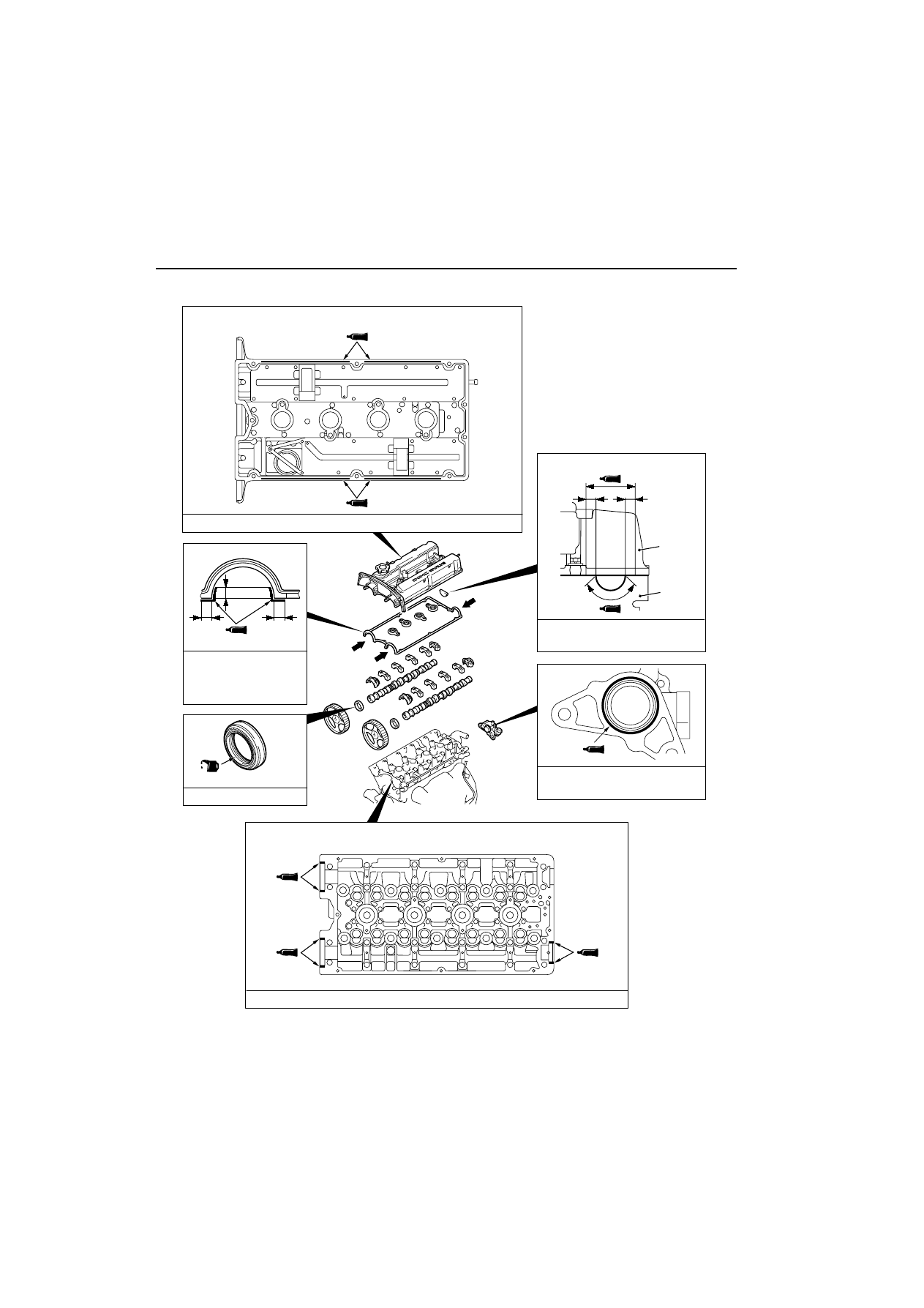

CAMSHAFT AND VALVE STEM SEAL

ENGINE MECHANICAL

11A-17

LUBRICATION AND SEALING POINTS

<The bottom view of the rocker cover>

Sealant: MITSUBISHI GENUINE PART MD970389 or equivalent

Engine oil

(Lip section)

10 mm

10 mm

10 mm

<View A>

Sealant: 3M ATD Part No.8660

or equivalent

10 mm

10 mm

Rocker

cover

Cylinder

head

φ

3 mm

AC300541

A

A

A

Sealant:

MITSUBISHI GENUINE

PART MD970389 or

equivalent

Sealant: MITSUBISHI GENUINE

PART MD970389 or equivalent

Sealant: MITSUBISHI GENUINE PART MD970389 or equivalent

<Top view of cylinder head>