Mitsubishi Montero (2004+). Manual - part 475

DIFFERENTIAL CARRIER ASSEMBLY

TSB Revision

REAR AXLE

27-39

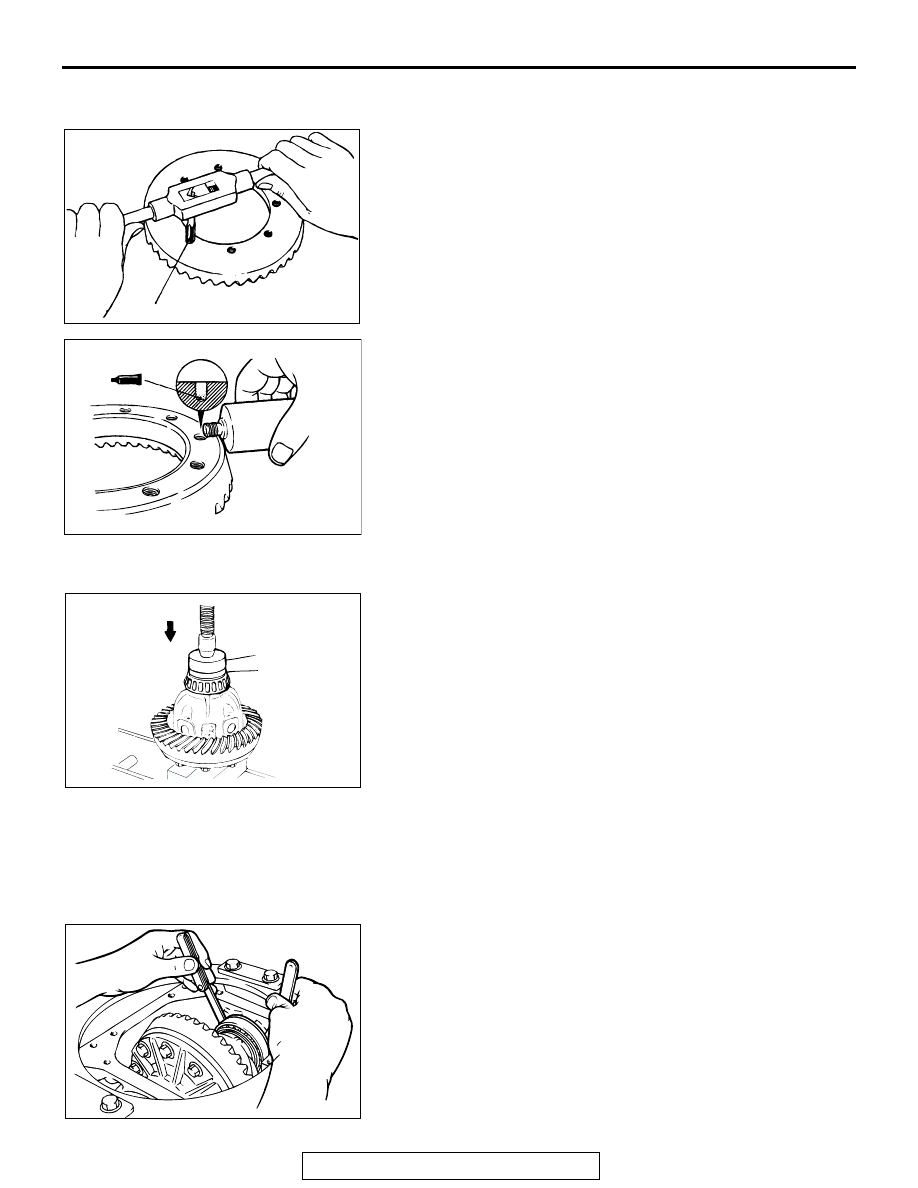

>>H<< DRIVE GEAR INSTALLATION

1. Clean the drive gear attaching bolts.

2. Remove the adhesive adhered to the threaded holes of the

drive gear by turning the tap (M10 x 1.25). Clean the

threaded holes by applying compressed air.

3. Apply 3M

stud locking 4170 or equivalent to the threaded

holes of the drive gear.

4. Install the drive gear onto the differential case with the

mating marks properly aligned. Tighten the bolts to the

specified torque in a diagonal sequence.

Tightening torque: 152

± 15 N⋅m (112 ± 10 ft-lb)

.

>>I<< SIDE BEARING INNER RACE INSTALLATION

Use special tools MD998812 and MD998829 to press-fit the

side bearing inner races into the differential case.

.

>>J<< BEARING CAP INSTALLATION/FINAL DRIVE GEAR

BACKLASH ADJUSTMENT

Adjust drive gear backlash as follows:

1. Assemble the differential case with the side bearing outer

race to the gear carrier.

2. Press the differential case to one side to measure the

clearance of the side bearing outer race and the gear carrier.

3. Select two pairs of side bearing spacer. Determine the

thickness by adding 1/2 of the clearance to the pre-load

0.05mm (0.002 inch).

ACX01068AB

TAP

ACX02430

ACX02431AB

MD998812

MD998829

ACX01071