Mitsubishi Montero (2002-2004). Manual - part 452

PISTON AND CONNECTING ROD

TSB Revision

ENGINE OVERHAUL

11B-41

REMOVAL SERVICE POINTS

.

<<A>> CONNECTING ROD CAP REMOVAL

1. Mark the cylinder number on the side of the connecting rod

big end for correct reassembly.

2. Keep the removed connecting rods, caps, and bearings in

order according to the cylinder number.

.

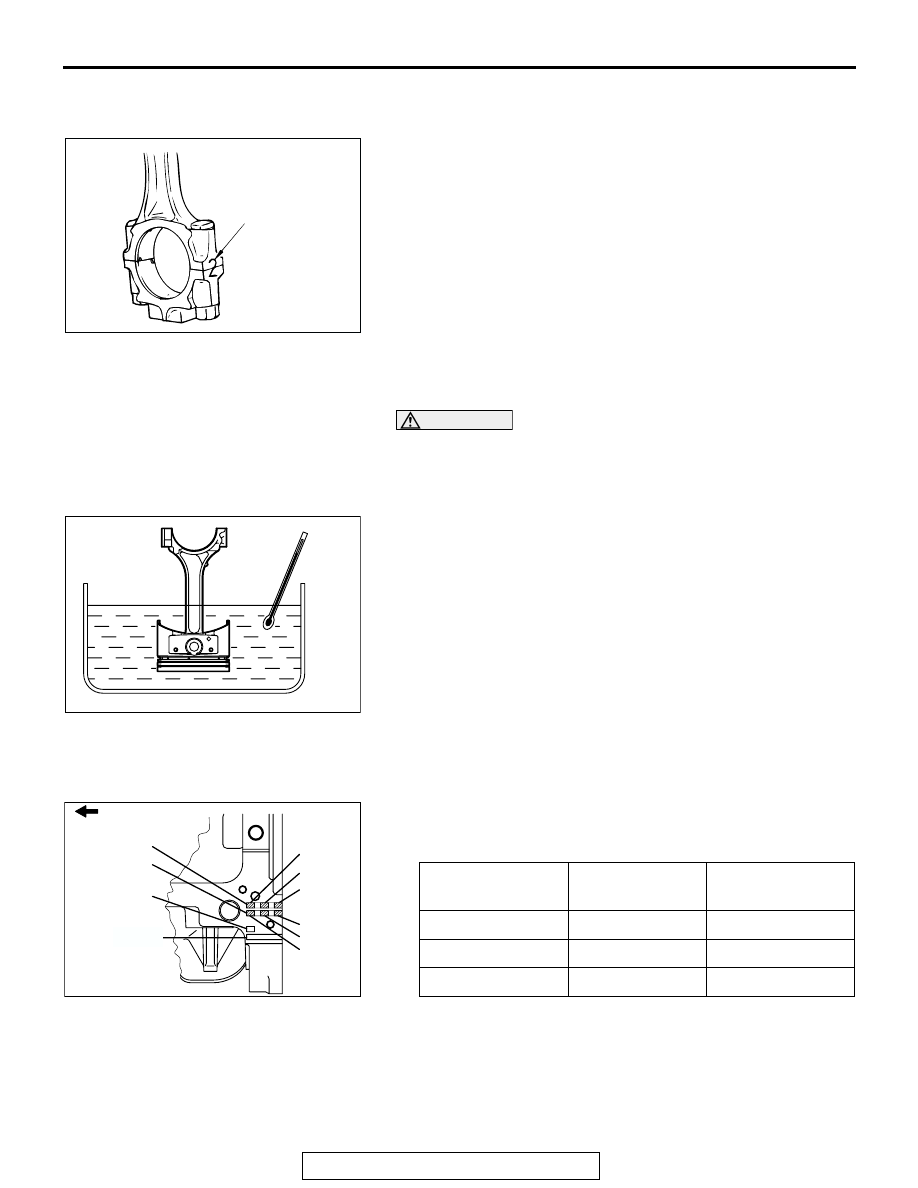

<<B>> PISTON PIN REMOVAL

1. Remove the snap rings.

CAUTION

The clearance between the piston and the piston pin is an

almost tight fit at room temperature. Therefore, be sure the

heat the piston before pulling out the piston pin. In addi-

tion, note that the piston is hot after heating.

2. Heat the piston approximately 70

°C (158°F) and pull out the

piston pin.

INSTALLATION SERVICE POINTS

.

>>A<< PISTON PIN INSTALLATION

1. When replacing the piston pin, read off the cylinder bore size

mark on the cylinder block as illustrated, and select a piston

according to the flowing table.

NOTE: The piston size mark shows on the top of the piston.

2. Set the snap ring into one side of the piston pin hole.

AKX00734

CYLINDER

NUMBER

AB

AKX01397

70˚C

(158˚F)

AB

CYLINDER BORE

SIZE MARK

PISTON CLASS PISTON SIZE

MARK

I

A

A

II

B

None

III

C

C

AK200850

TIMING BELT SIDE

CHECK DEGIT

No.4

No.1

No.2

No.3

AC

LEFT BANK

RIGHT BANK

No.6

No.5

CRANKSHAFT

BORE SIZE

MARK