Mitsubishi Montero (2002-2004). Manual - part 451

OIL PAN AND OIL PUMP

TSB Revision

ENGINE OVERHAUL

11B-37

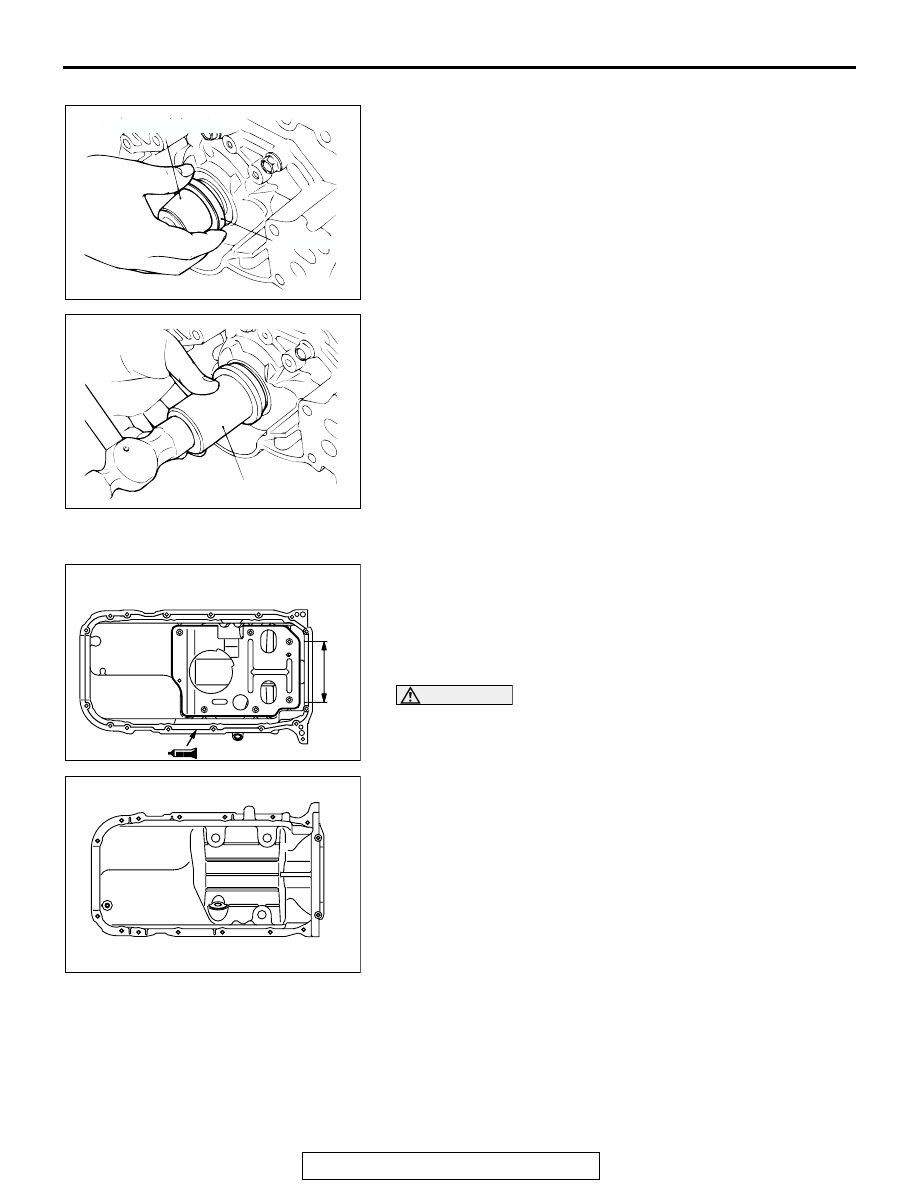

>>B<< CRANKSHAFT OIL SEAL INSTALLATION

1. Install the guide of special tool MD998717 to the front end of

the crankshaft.

2. Apply engine oil to the lip area of a new oil seal and push it

in until it contacts the oil pump case.

3. Using special tool MD998717, press-fit the oil seal into the

oil pump case.

.

>>C<<OIL PAN INSTALLATION

1. Clean the gasket surfaces of the cylinder block and upper oil

pan.

2. Apply a 4 mm (0.2 inch) diameter bead of sealant Mitsubishi

Genuine Parts number MD970389, or equivalent to the oil

pan. Be sure to install the oil pan quickly while the sealant is

wet (within 15 minutes).

CAUTION

When installing the upper oil pan, be sure not to expel the

sealant from the oil pan flange at portion A in the illustra-

tion.

3. Tighten the upper oil pan bolts in the sequence shown.

Tightening torque: 9

± 3 N⋅m (80 ± 26 in-lb)

4. After installation, keep the sealed area away from the oil and

coolant for approximately one hour.

.

AKX00659 AB

MD998717 (GUIDE)

OIL SEAL

AKX00660

MD998717

AB

AKX01403AB

LIQUID GASKET APPLICATION AREA

(TOP VIEW)

A

AKX01404AC

1

5

11

14

15

10

6

2

3

7

12

16

9

13

8

4

FLANGE BOLT TIGHTENING

SEQUECE(BOTTOM VIEW)