Mitsubishi Montero (2002-2004). Manual - part 450

CYLINDER HEAD AND VALVES

TSB Revision

ENGINE OVERHAUL

11B-33

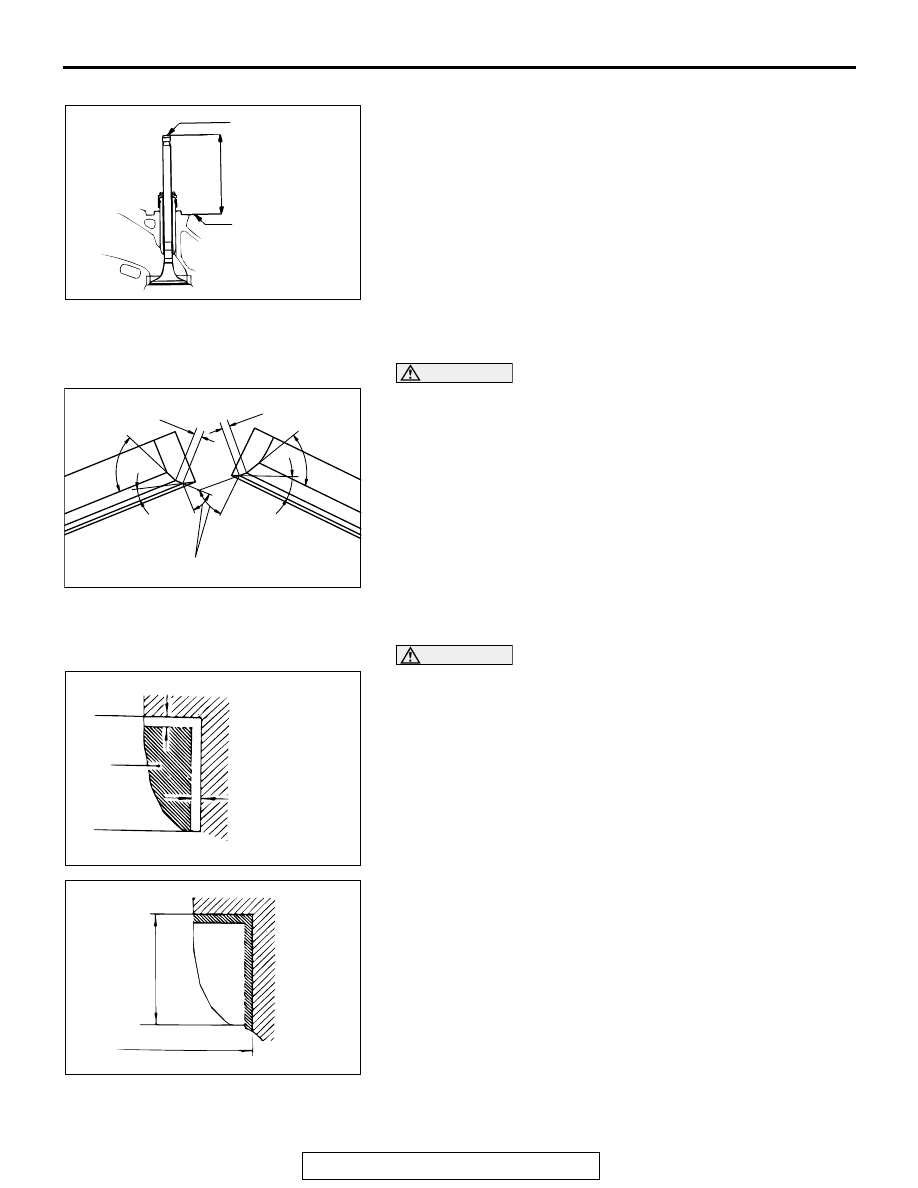

VALVE SEAT

Assemble the valve, then measure the valve stem projection

between the end of the valve stem and the spring seating sur-

face. If the measurement exceeds the specified limit, replace

the valve seat.

Standard value:

<Intake> 48.30 mm (1.9021 inches)

<Exhaust>51.71 mm (2.039 inches)

Limit:

<Intake> 48.80 mm (1.921 inches)

<Exhaust> 52.01 mm (2.048 inches)

.

VALVE SEAT RECONDITIONING PROCEDURE

CAUTION

Before correcting the valve seat, check for the clearance

between the valve guide and valve and, if necessary,

replace the valve guide.

1. Using the special tool or a seat grinder, correct to obtain the

specified seat width and angle.

2. After correcting the valve seat, lap the valve and valve seat

using lapping compound. Then, check the valve stem

projection.

.

VALVE SEAT REPLACEMENT PROCEDURE

CAUTION

Before replacing the valve seat, check the valve guide and,

if necessary, replace the valve guide.

1. Cut the valve seat from the inside to thin the wall thickness.

Then, remove the valve seat.

2. Rebore the valve seat hole in the cylinder head to a selected

oversize valve seat diameter.

Seat ring hole diameter:

Intake valve

0.3 oversize 37.80

− 37.83 mm (1.4882 − 1.4894 inches)

0.6 oversize 38.10

− 38.13 mm (1.5000 − 1.5012 inches)

Exhaust valve

0.3 oversize 34.80

− 34.83 mm (1.3701 − 1.3713 inches)

0.6 oversize 35.10

− 35.13 mm (1.3819 − 1.3831 inches)

3. Before fitting the valve seat, either heat the cylinder head up

to approximately 250

°C (482°F) or cool the valve seat in

liquid nitrogen, to prevent the cylinder head bore from

galling.

AKX00695

SPRING SEATING

SURFACE

VALVE STEM END

VALVE STEM

PROJECTION

AB

AK101830AB

0.9

– 1.3 mm

0.9 – 1.3 mm

65˚

65˚

15˚

25˚

43.5˚

– 44˚

AKX00610

0.5 – 1 mm

(0.020 – 0.039 in)

0.5 – 1 mm (0.020 – 0.039 in)

CUT

AWAY

AB

AKX00611

HEIGHT OF

SEAT RING

OVERSIZE DIAMETER

AB