Mitsubishi Montero (2002-2004). Manual - part 448

ROCKER ARMS AND CAMSHAFT

TSB Revision

ENGINE OVERHAUL

11B-25

ROCKER ARM

1. Check the roller surface and replace the rocker arm if

recesses, damage or heat seizure is observed.

2. Check roller rotation and replace the rocker arm if uneven

rotation or roller backlash of the roller is observed.

3. Check the inside diameter and replace the rocker arm if

damage or seizure is observed.

.

CAMSHAFT

1. Check the camshaft bearing journals for damage and

binding. If the journals are binding, check the cylinder head

for damage. Also check the cylinder head for clogged oil

holes.

2. Check the tooth surface of the distributor drive gear teeth of

the camshaft and replace if abnormal wear is evident.

3. Check the cam surface for abnormal wear and damage and

replace if necessary. Also measure the cam height and

replace if out of minimum limit.

Standard value:

Intake 37.39 mm (1.472 inches)

Exhaust 37.14 mm (1.462 inches)

Minimum limit:

Intake 36.89 mm (1.452 inches)

Exhaust 36.64 mm (1.443 inches)

.

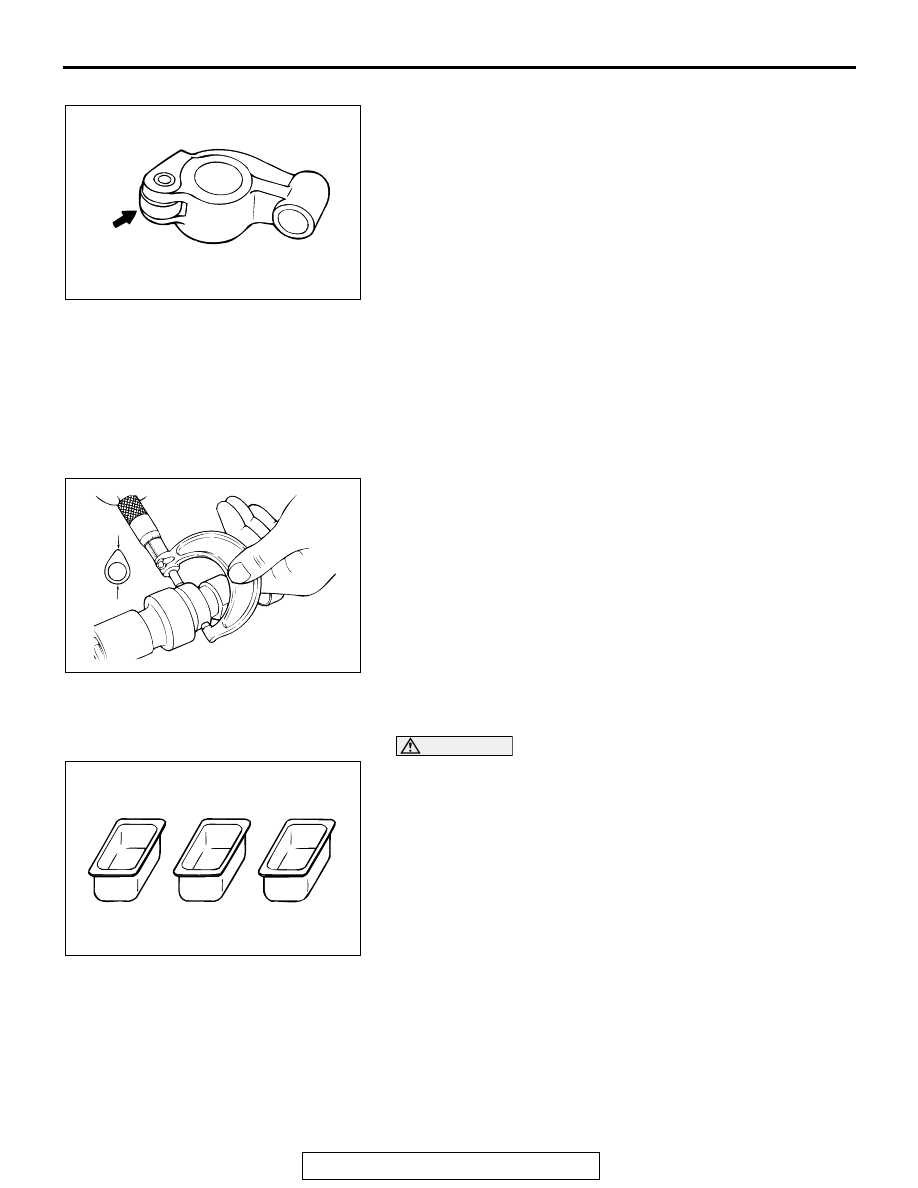

LASH ADJUSTERS

CAUTION

• The lash adjusters are precision-engineered mecha-

nisms. Do not allow them to become contaminated by

dirt or other foreign substances.

• Do not attempt to disassemble the lash adjusters.

• Use only fresh diesel fuel to clean the lash adjusters.

1. Prepare three containers and approximately 5 dm

3

(30.5

quart) of diesel fuel. Into each container, pour enough diesel

fuel to completely cover a lash adjuster when it is standing

upright. Then, perform the following steps with each lash

adjuster.

AKX00723

ROLLER TIP

AB

AKX00685

AKX00625

OUTSIDE

CLEANING

INSIDE

CLEANING

FILLING

DIESEL FUEL

A

B

C

AB