Mitsubishi Montero (2002-2004). Manual - part 453

PISTON AND CONNECTING ROD

TSB Revision

ENGINE OVERHAUL

11B-45

>>E<< PISTON AND CONNECTING ROD INSTALLATION

1. Liberally coat the circumference of the piston, piston ring,

and oil ring with engine oil.

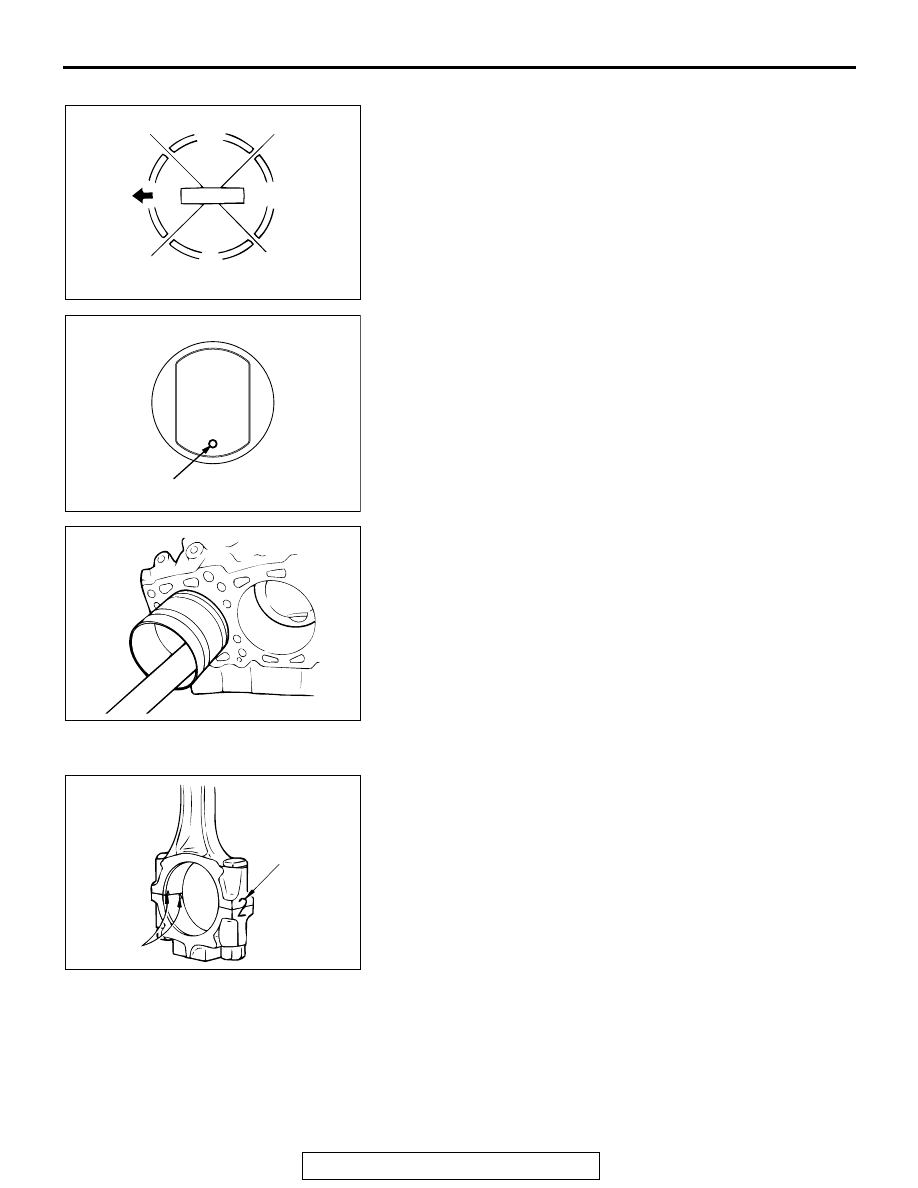

2. Arrange the piston ring and oil ring gaps (side rail and

spacer) as shown in the illustration.

3. Rotate the crankshaft so that the crank pin is on the center

of the cylinder bore.

4. Insert the piston and connecting rod assembly into the

cylinder with the front mark on the piston crown pointing to

the timing belt side.

5. Using a suitable piston ring compressor tool, install the

piston and connecting rod assembly into the cylinder block.

.

>>F<< CONNECTING ROD CAP INSTALLATION

1. Verifying the mark made during disassembly, install the

bearing cap to the connecting rod. If the connecting rod is

new with no index mark, make sure that the bearing locking

notches are on the same side as shown.

AKX00620

UPPER

SIDE RAIL

NO.1

PISTON PIN

TIMING

BELT SIDE

LOWER

SIDE RAIL

NO.2 RING GAP

AND SPACER GAP

AB

AK201081AB

FRONT MARK

AKX00721

AKX00735

CYLINDER NO.

NOTCHES

AB