Mitsubishi Galant (2004+). Manual - part 135

ON-VEHICLE SERVICE

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-13

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

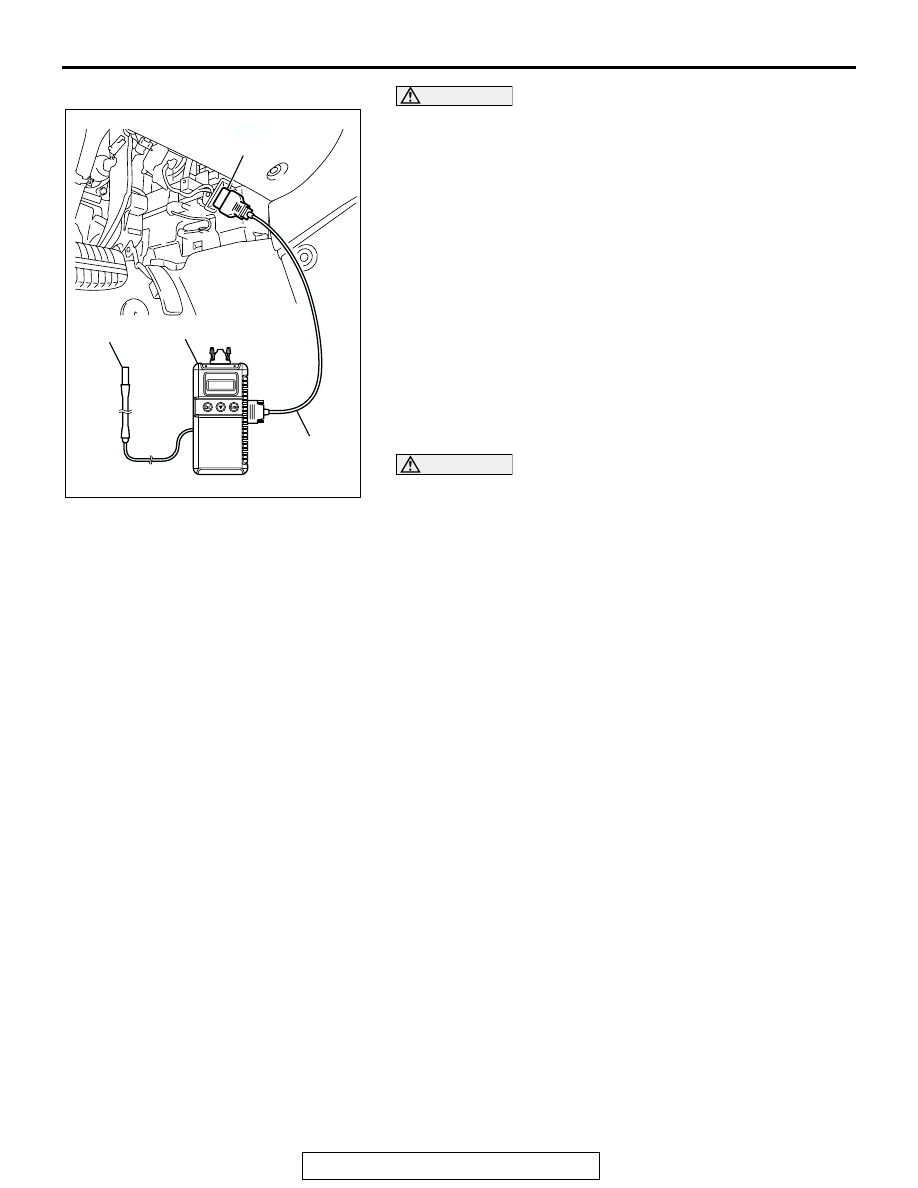

2. Connect scan tool MB991958 to the data link connector.

3. Set up a timing light.

4. Start the engine and run it at idle.

5. Check that the idle speed is approximately 700 r/min.

6. Select scan tool MB991958 actuator test "item number 17".

7. Check that basic ignition timing is within the standard value.

Standard value: 5

° BTDC ± 3°

8. If the basic ignition timing is not within the standard value,

check the following items:

• Diagnostic output

• Timing belt cover and crankshaft position sensor installation

conditions

• Crankshaft sensing blade condition

CAUTION

If the actuator test is not canceled, the forced drive will

continue for 27 minutes. Driving in this state could lead to

engine failure.

9. Press the clear key on scan tool MB991958 (select forced

drive stop mode), and cancel the actuator test.

10.Check that the actual ignition timing is at the standard value.

Standard value: Approximately 10

° BTDC

NOTE: Ignition timing fluctuates about

±

7

°

Before Top Dead

Center, even under normal operating condition.

NOTE: It is automatically further advanced by about 5

°

to

10

°

Before Top Dead Center at higher altitudes.

CURB IDLE SPEED CHECK

M1111003500568

Required Special Tool:

MB991958: Scan Tool (MUT-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: MUT-III USB Cable

• MB991910: MUT-III Main Harness A

1. Before checks, set the vehicle in the following condition.

• Engine coolant temperature: 80 − 95°C (176 − 203°F)

• Lights and all accessories: OFF

• Transaxle: P range

NOTE: Vehicles for Canada, the headlight, taillight, etc.

remain lit even when the lighting switch is in "OFF" position

but this is no problem for checks.

AC302077

AC305412

AC306958AB

MB991824

MB991910

MB991668

DATA LINK

CONNECTOR