Mitsubishi Galant (2004+). Manual - part 134

ON-VEHICLE SERVICE

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-9

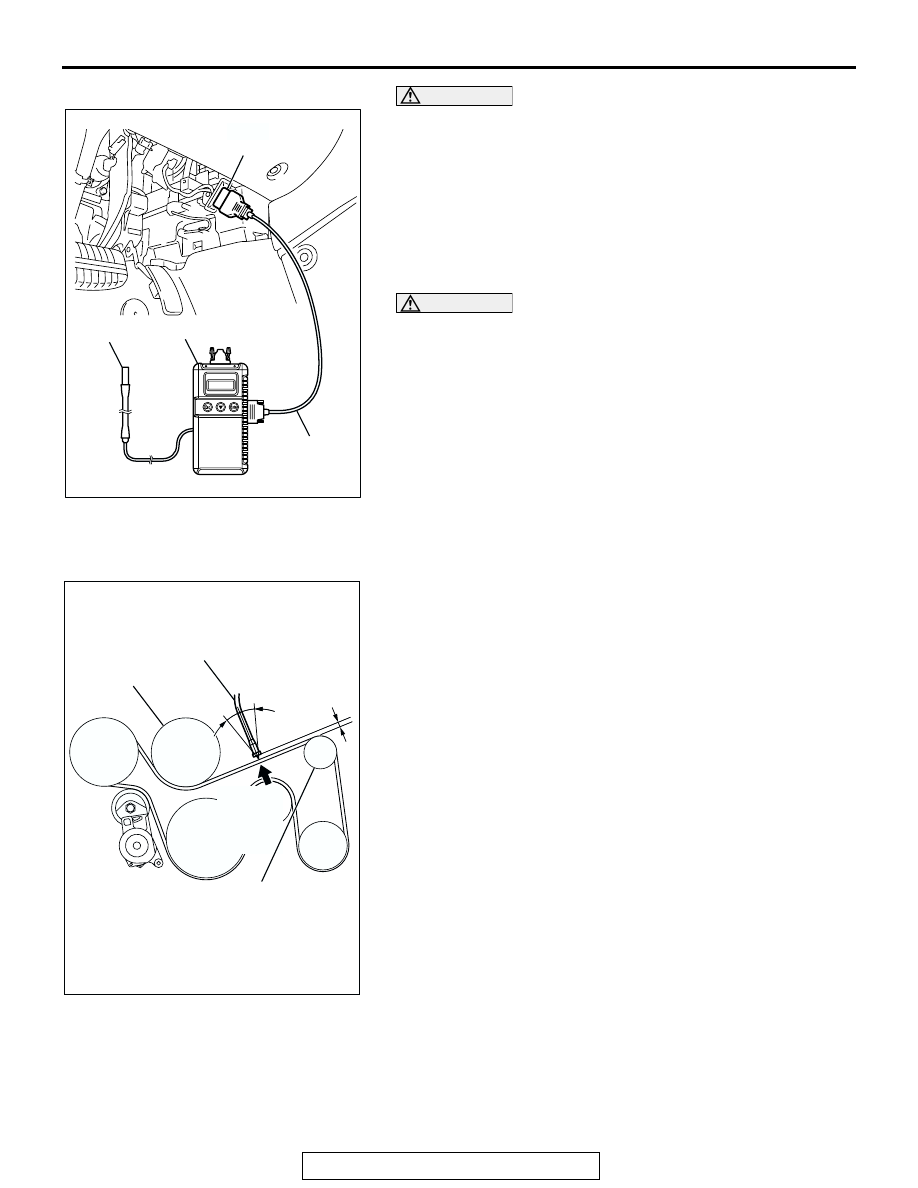

CAUTION

To prevent damage to scan tool MB991824, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991824.

(1) Connect special tool MB991668 to scan tool MB991824.

(2) Connect scan tool MB991910 to scan tool MB991824.

(3) Connect scan tool MB991910 to the data link connector.

(4) Turn the ignition switch to the "ON" position and select

"Belt Tension" from the menu scan tool MB991824

screen.

CAUTION

• The temperature of the surface of the belt should be as

close to normal temperature as possible.

• Do not allow any contaminants such as water or oil to

get onto the microphone.

• If strong gusts of wind blow against the microphone or

if there are any loud sources of noise nearby, the val-

ues measured by the microphone may not correspond

to actual values.

• If the microphone is touching the belt while the mea-

surement is being made, the values measured by the

microphone may not correspond to actual values.

• Do not take the measurement while the vehicle's engine

is running.

(5) Hold special tool MB991668 to the middle of the drive

belt between the pulleys (at the place indicated by arrow),

approximately 10

− 20 mm (0.40 − 0.78 inch) away from

the rear surface of the belt so that it is perpendicular to

the belt (within an angle of

± 15 degree).

(6) Gently tap the middle of the belt between the pulleys (the

place indicated by the arrow) with your finger as shown in

the illustration, and measure that the vibration frequency

of the belt is within the standard value.

Standard value: 120

− 154 Hz

3. If not within the standard value, replace the auto-tensioner.

(Refer to

).

.

AC302077

AC305412

AC306958AB

MB991824

MB991910

MB991668

DATA LINK

CONNECTOR

AC301266AB

MB991668

10 – 20 mm

(0.40 – 0.78 in)

WATER

PUMP

PULLEY

GENTLY

TAP WITH

YOUR

FINGER

15˚

15˚

GENERATOR

PULLEY