Content .. 1628 1629 1630 1631 ..

Mitsubishi Galant 9G. Manual - part 1630

ON-VEHICLE SERVICE

TSB Revision

ANTI-LOCK BRAKING SYSTEM (ABS)

35B-104

12.After inspection, disconnect scan tool MB991958

immediately after turning the ignition switch to the "LOCK"

(OFF) position.

IN THE EVENT OF A DISCHARGED BATTERY

M1352003500547

WARNING

If the ABS is not operating, the vehicle will be unsta-

ble during braking, Do not drive the vehicle with the

ABS-ECU connector disconnected or with the ABS

not operating.

If the engine is started using a booster cable when the battery

is completely flat, and the vehicle is then driven without waiting

for the battery to be recharged, the engine may misfire and it

may not be possible to drive the vehicle. This is because the

ABS consumes a large amount of current when carrying out its

initial checks. If this happens, recharge the battery fully.

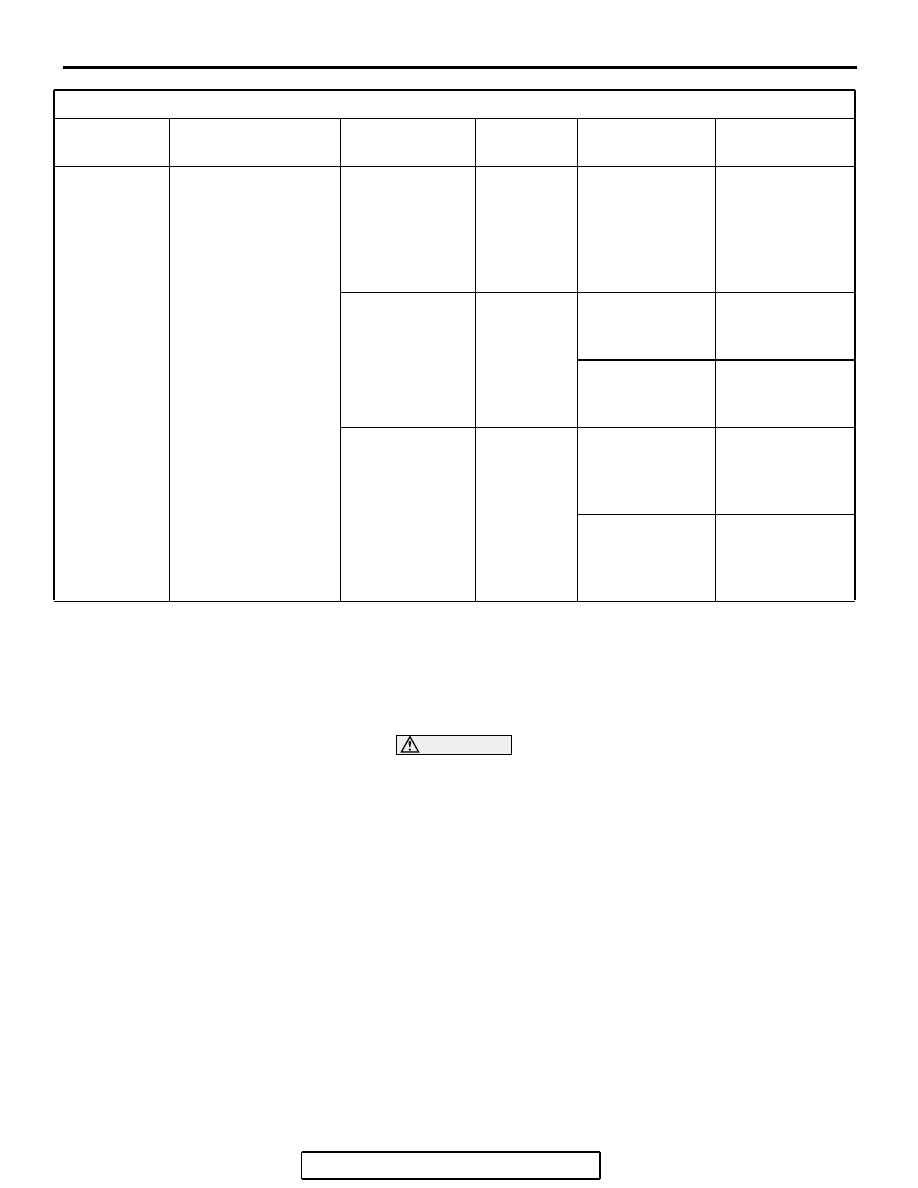

DIAGNOSIS TABLE

MUT-III

DISPLAY

OPERATION

INSPECTION

RESULT

JUDGMENT PROBABLE

CAUSE

REMEDY

01 FR VALVE

02 FL VALVE

03 RR VALVE

04 RL VALVE

• Depress brake

pedal to lock

wheel.

• Using scan tool

MB991958, select

the wheel to be

checked and force

the actuator to

operate.

• Turn the selected

wheel manually to

check the change

of brake force.

Brake force is

released for

three seconds

after wheels

have been

locked.

Normal

−

−

Wheel does not

lock when brake

pedal is

depressed.

Abnormal

Clogged brake

line other than

hydraulic unit

Check and clean

brake line

Clogged

hydraulic circuit

in hydraulic unit

Replace

hydraulic unit

assembly

Brake force is

not released

Abnormal

Incorrect

hydraulic unit

brake tube

connection

Connect correctly

Hydraulic unit

solenoid valve

not functioning

correctly

Replace

hydraulic unit

assembly