Mitsubishi Lancer Evolution X. Manual - part 70

CAMSHAFT

TSB Revision

ENGINE MECHANICAL

11A-33

<<H>> POWER STEERING OIL PUMP ASSEMBLY

REMOVAL

1. With the hose installed, remove the power steering oil pump

assembly from the bracket.

2. Tie the removed power steering oil pump assembly with a

string at a position where it will not interfere with the removal

and installation of oil control valve.

.

<<I>> OIL FEEDER CONTROL VALVE REMOVAL

CAUTION

After removal of the oil feeder control valve, be careful to

prevent dust from getting into the oil passage in the cylin-

der head.

INSTALLATION SERVICE POINTS

.

>>A<< O-RING/OIL FEEDER CONTROL VALVE

INSTALLATION

CAUTION

When installing the oil control valve, be careful to avoid

damage to the O-ring.

Apply engine oil to the O-ring of the oil feeder control valve and

install the oil feeder control valve to the cylinder head.

.

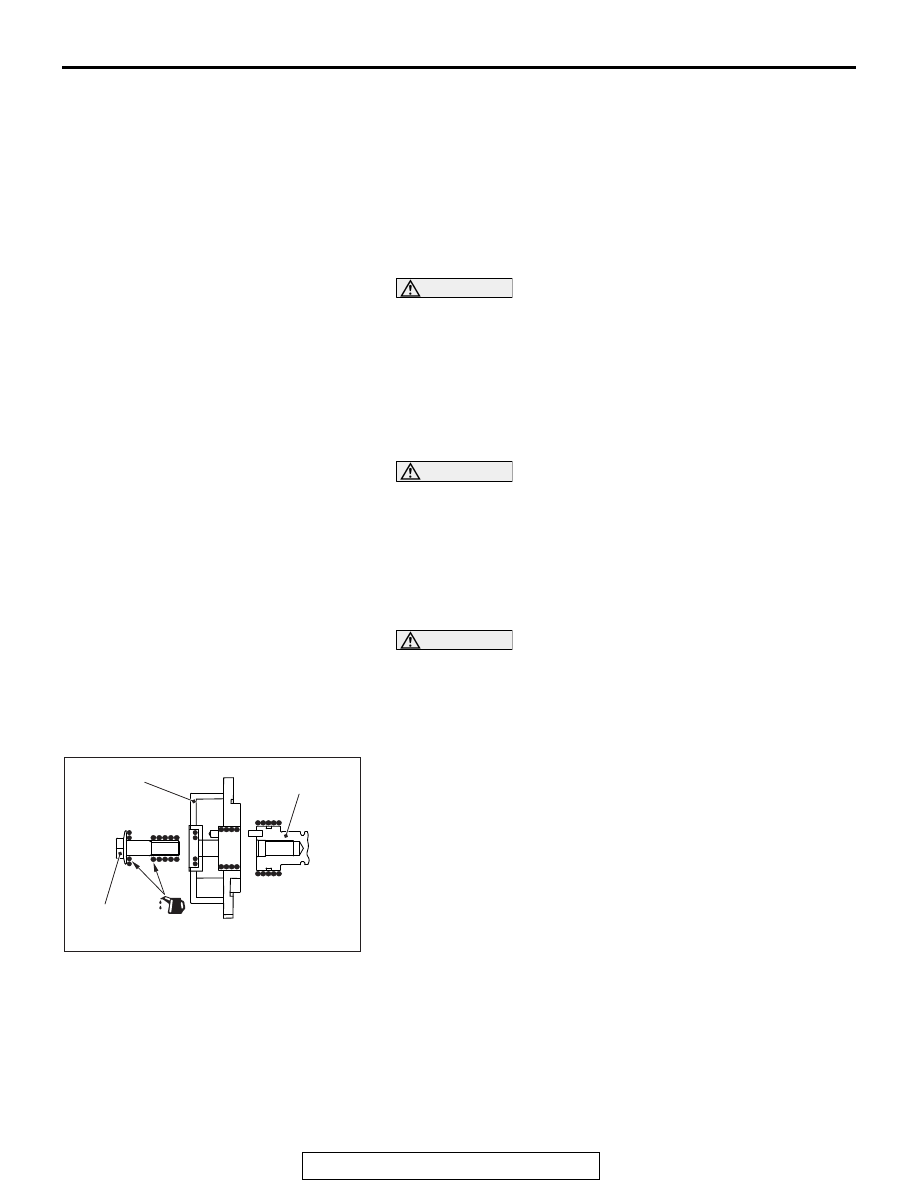

>>B<< CAMSHAFT/CAMSHAFT SPROCKET

INSTALLATION

CAUTION

The camshaft sprocket bolt cannot be reused.

Install the camshaft and camshaft sprocket assembly as fol-

lows.

1. Check that the knock pin is set to the right overhead

position.

2. an adequate and minimum amount of engine oil to the outer

of the camshaft edge and the entire insertion area around

camshaft sprocket assembly.

3. Set the knock pin hole of camshaft sprocket assembly to the

right overhead position, and slowly insert it into the camshaft

assembly to the specified position.

4. Install the camshaft sprocket to the camshaft.

5. Apply an adequate and minimum amount of engine oil to the

thread of the camshaft sprocket bolt and the lower area of

the flange.

AC708506AC

Camshaft

Camshaft

sprocket

Camshaft

sprocket bolt