Mitsubishi Lancer Evolution 8. Manual - part 8

POWER TRAIN – MANUAL TRANSMISSION

2-11

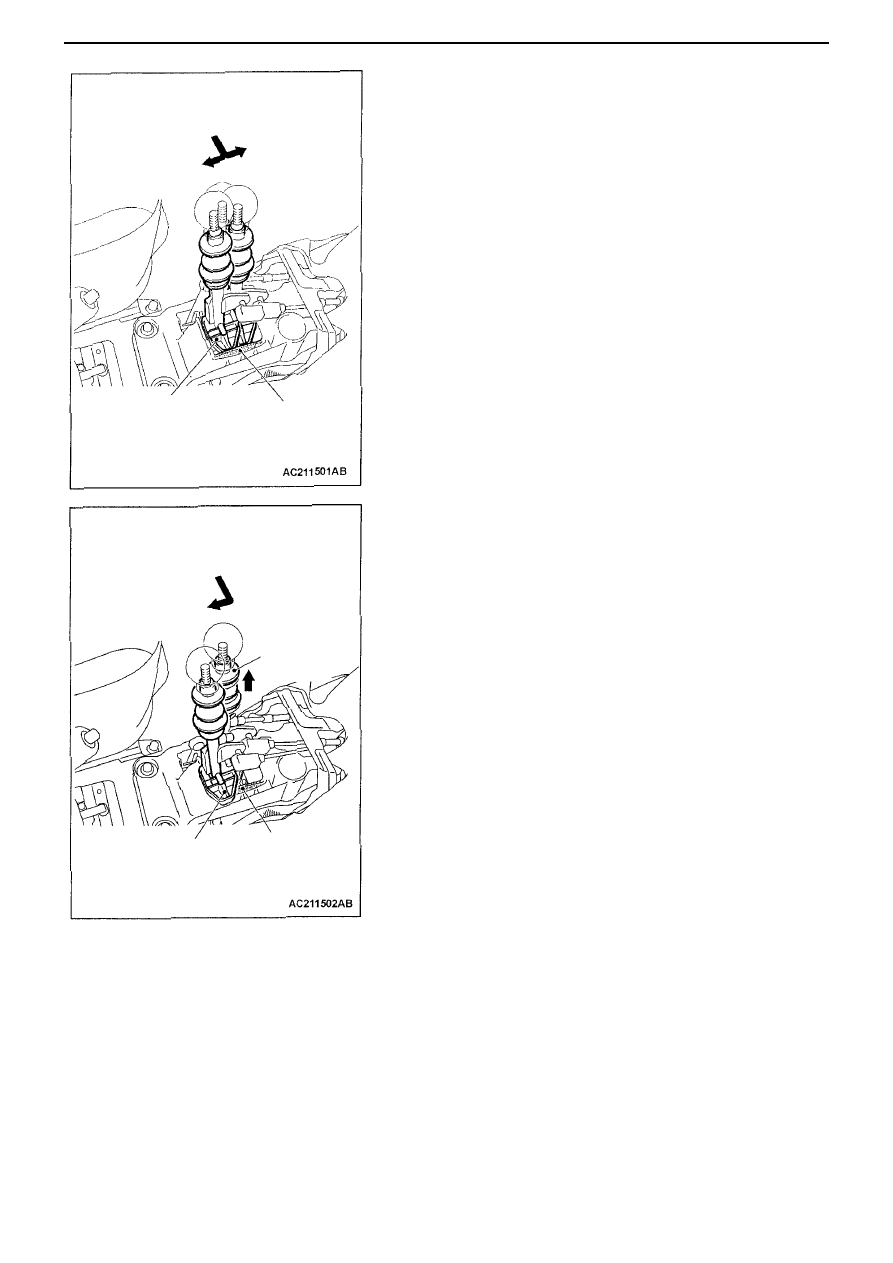

Reverse Gear protection when changing into 5

th

or 6

th

gear

The lock moves against the base bracket when shifting to 5

th

or 6

th

gear,

thus preventing a change into reverse.

When engaging reverse

Reverse can be engaged by pulling up the collar beneath the gear knob

Engaging to

5

th

gear

Engaging to

6

th

gear

Lock

Base bracket

Engaging reverse

Lift the collar

Lock

Base bracket