Mitsubishi Lancer Evolution VI. Manual - part 115

HEATER AND MANUAL AIR CONDITIONER –

On-vehicle Service

55-12

Caution

(1) To connect the quick joint, press section “A” firmly

against the service valve until a click is heard.

(2) When connecting, run your hand along the hose

while pressing to ensure that there are no bends

in the hose.

5.

Start the engine.

6.

Set the blower switch to HI (Fast) position

7.

Set the A/C switch to ON position

8.

Set the temperature control to Max. cooling position

9.

Set the mode selection to Face position

10. Set the air selection to Recirculation position

11. Fix engine speed to 1,500 r/min.

12. Check that the high-pressure side pressure is 1,667 –

1,765 kPa.

NOTE

If the pressure is not within this range, adjust it as follows;

cool down the condenser using a cooling fan if the

pressure is higher, and cover the condenser to protect

it from ventilation air if it is lower.

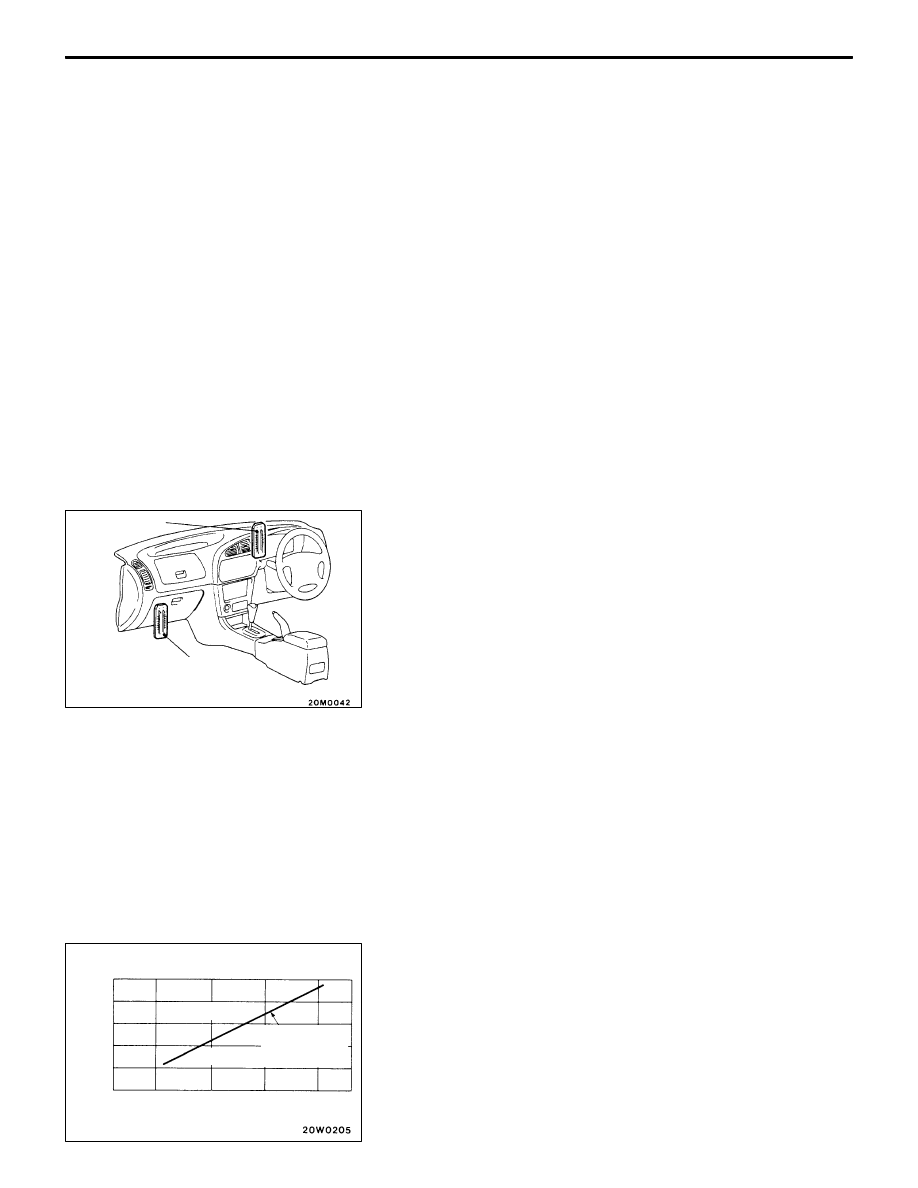

13. Set a dry-bulb/wet-bulb thermometer at the air inlet, and

set a dry-bulb thermometer at the air outlet.

Caution

(1) Set the dry-bulb thermometer at a position where

the temperature sensing section can be directly

blown with cooled air.

(2) Place the dry-bulb/wet-bulb thermometer at a

position where it is not exposed to cooled air

blown out.

14. After the temperature of the air blown out from the air

outlet has been stabilized (10 – 15 minutes after starting),

read the dry-bulb thermometer set at the air outlet and

the wet-valve thermometer set at the air inlet.

15. The air conditioning system is considered in good

condition if the intersecting point of the measurements

obtained in Step (14) is below the performance evaluation

reference line on the graph.

Caution

Do not remove the quick joint immediately after the

performance test has been completed. Stop the engine

and wait until the high-pressure side pressure of the

gauge manifold has been lowered sufficiently.

Dry-bulb ther-

mometer

Dry-bulb/wet-bulb

thermometer

Reading of wet-bulb thermometer

set at air inlet (

°

C)

Performance

evaluation

reference line

In order

Not in order

0

Reading of dry-bulb

thermometer set at air outlet

(

°

C)

15

20

25

30

5

10

15

20

25